Josh Shapiro, LA-based Watchmaker, on Becoming a Rare, Vertically Integrated American Manufacture

Or how high-end independent watchmaking can come back to the US.

Josh Shapiro seems like an unlikely person to help restore traditional watchmaking in the United States. He started as a pole vault coach and a school teacher before becoming the administrator of a private school. Growing up in a machine shop gave him an appreciation for metals and working with his hands, and a flashy Chronoswiss Opus poster in a local shop helped spark his interest in watchmaking. With some formal training, a lot of practice with ETA 6498 movements and a passion to work with his hands, Josh Shapiro began producing watch dials and found an industry legend as a mentor, David Walter. Now in a new atelier in Inglewood, California, Josh produces luxury, custom pieces and is putting the final touches on an in-house, hand-wound calibre with a tourbillon moon phase also in the works. His current collection is called the Infinity Series.

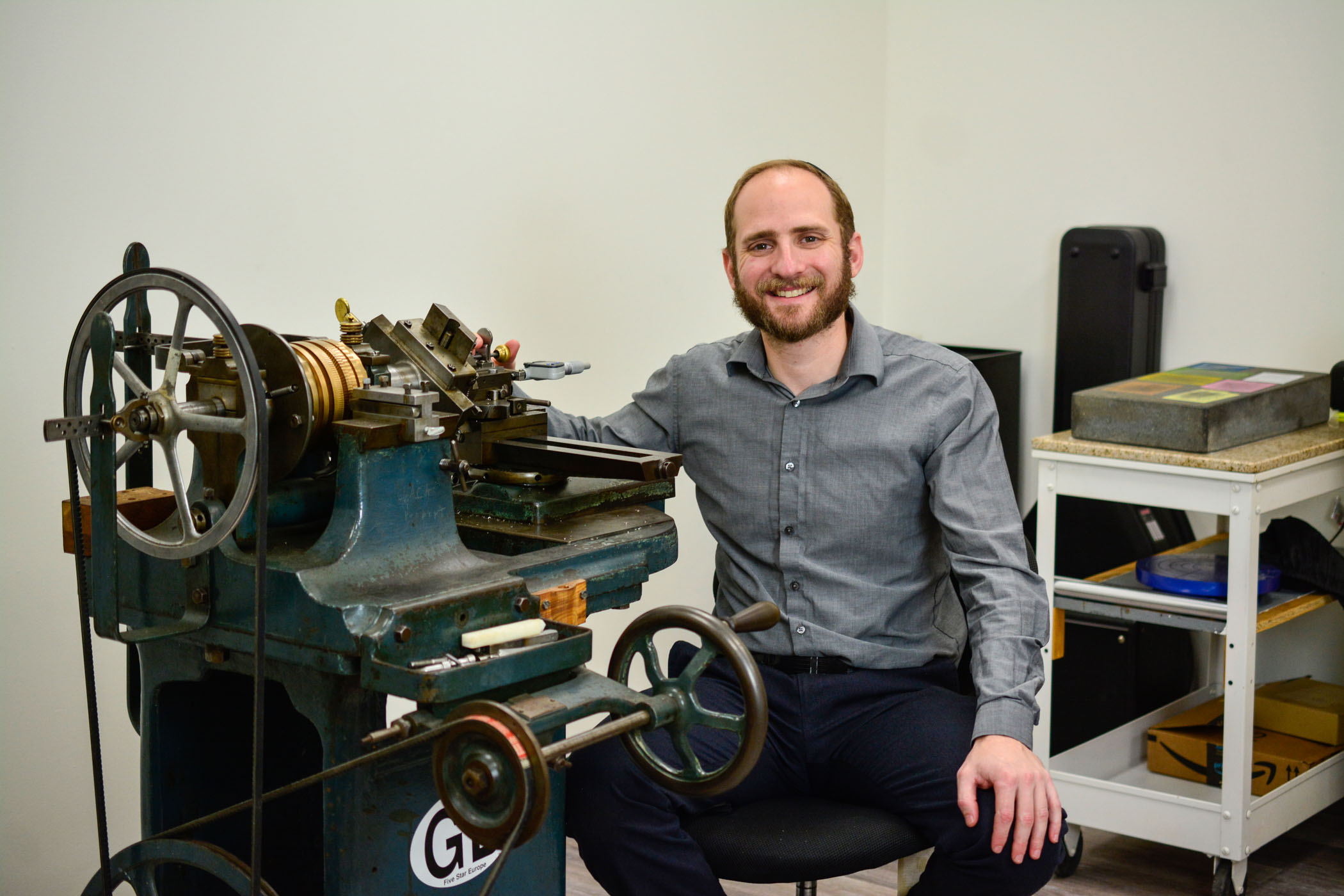

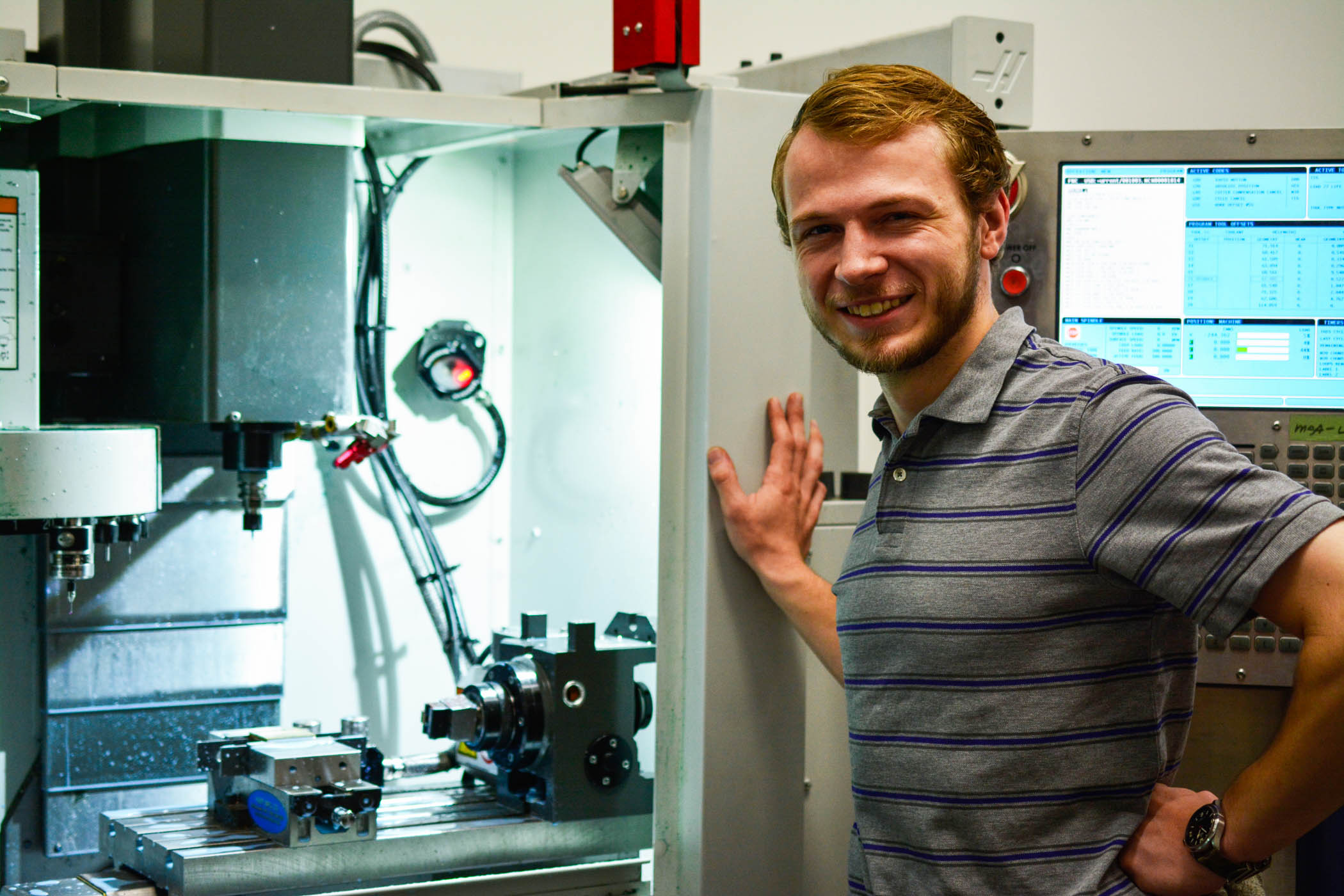

J.N. Shapiro employs two additional watchmakers as Josh also continues his role as a school principal and teacher. Artur Akmaev is a renowned hand-engraver, skeletonizer and hand finisher, while Eric Storlie is a SAWTA trained (Swiss American Watchmakers Training Alliance) watchmaker, an accomplished horological machinist and experienced watch restorer. Josh himself focuses on horological machining and engine turning dials. I recently met all three at his shop and we talked about his early life, the relatively new company and development of in-house movements, and the future of American watchmaking.

Erik Slaven, MONOCHROME – Hi Josh, thanks for taking some time out of your busy day. My first question is one we often start with at MONOCHROME. What is your earliest horological memory? Was there a particular watch that sparked your interest?

Josh Shapiro, J.N. Shapiro Watches – I guess my oldest horological memory goes back to my grandfather when he would carry his wristwatch in a pocket. He took off the straps and just had it in his pocket.

So, he literally used a wristwatch as a pocket watch…

Yeah, it was interesting. I’d say what really got me into watches was when I walked into the local watch store here in Los Angeles, Feldmar, and they had this big, beautiful poster of a Chronoswiss Opus chronograph. You could really see all of the inner workings of the chronograph and the different wheels and such.

Yes, they really pioneered the skeletonized chronograph.

I was just mesmerized when I saw that. It was right around the time I got married and I hadn’t done anything with my hands for a long time, so I was like, “I want to do that. I want to skeletonize a watch”. And that’s what really started everything for me. So, for the next year, I was just learning watchmaking and skeletonizing just for fun.

Ok, so this was just for your own pleasure.

Yes, it definitely started as a hobby. At that point, I was a full-time teacher and not even an administrator yet. I was still going to school getting my Master’s in history and watchmaking was just for fun.

Very interesting. So, outside of the world of horology, you’re an experienced teacher and now a high school principal. Do you try to bring watchmaking and this passion into the classroom?

Yes, well, first of all, I’m now a part-time principal and watchmaking is now my full-time gig. However, I do still teach a bit and one of the classes is a STEM class – Science, Technology, Engineering, Mathematics – and for that, you can bring in watchmaking machines and have the students work on them. From there, I’ve had some apprentices during the summer and have seen some really talented kids that I’ve invited to work in my workshop. Just yesterday, I brought a small milling machine into the STEM classroom and we’ve also done a lot of CAD design and 3D design. They always like to see the watches I’m working on. I’ve had talented students come here during the summer and help me with watches, and some have gotten better at CAD design than even myself.

Very cool, do you ever have a formal internship program?

Oh yeah, in the summer I’ve had internships with some of the high school students. They’d work for the summer and it’s really fun.

It’ll be interesting to see if they move on to become watchmakers themselves.

Yeah, definitely.

So, as we talked earlier you have a love for history and also grew up in a machine shop. I’m assuming that was your father’s.

Father’s and grandfather’s.

How did that help lead to watchmaking? Was it just a passion to work with your hands or with metals?

Well, I just grew up so much around metals and machines. Three months of the year I’d be there and there’d also be trees and junk to explore, but oftentimes I’d just be tinkering around the shop. I really liked hammering and anvils, and that was a big part of my childhood. By the time I was in high school, I wasn’t going into my father’s shop anymore, I was doing my own thing. I kind of just forgot about that whole side of myself. I’d say by the time I got married, it all just really came back to me.

Was this in LA County?

Yes, I grew up in Arcadia and the shop was in El Monte.

Ok, so you started this as a hobby. I’m assuming you were skeletonizing off-the-shelf ETA movements.

Yes, just 6498 movements to start with.

And you also worked through the British Horological Institute’s Distance Learning Program.

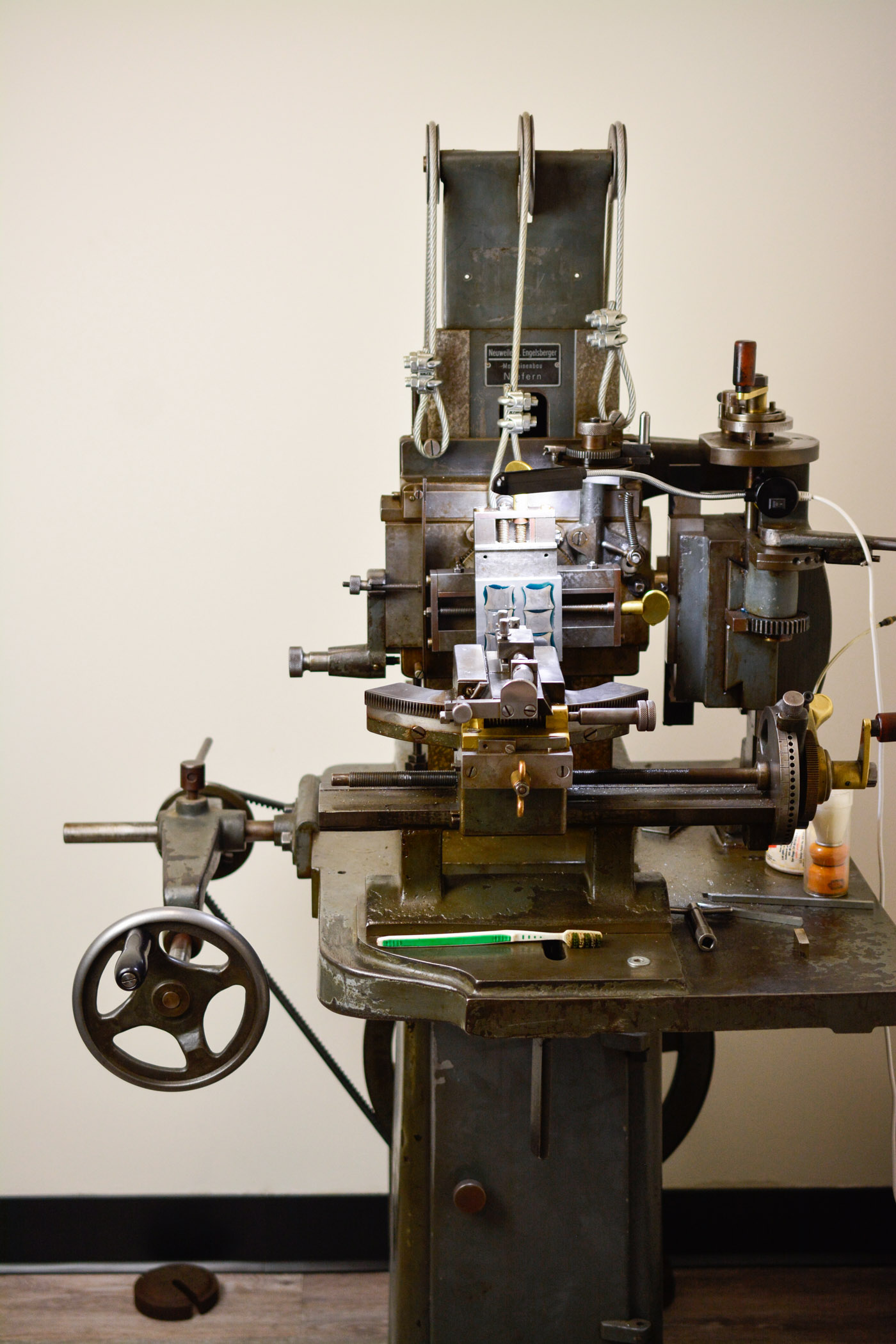

Yes, I worked with their Distance Learning Program and it was really nice. They send you a whole curriculum and you buy the materials, and then just work through the curriculum. In the end, you’re supposed to fly to Great Britain and take a test. I never did that. I could never get away and the money I was actually saving up for the trip ended up going towards engine turning machines. I guess I really burned that bridge. It’s ok, though. I realized that I was never going to go into servicing and sit there at a bench all day doing that. I definitely like the production side of things. By the time I finished that course, I was already really getting into guilloché and dial-making and machining and was onto a different phase than just the pure horological side of things.

When you were skeletonizing these early ETA 6498 movements, did you do anything with them or sell them?

Yes, well I sold them to some friends and family. They were definitely amateur watches in the big scheme of things. There was one person, maybe six or seven years ago, and he wanted a watch with a dial, not skeletonized. He also wanted me to turn this into a business. I didn’t know if it would ever turn into anything, but I made his watch with a dial and, you know, it was all right. When I started making that dial, however, I started really looking into dial-making. I had already read George Daniels’ Watchmaking, but then I started really paying attention to the engine turning section. That’s when I got the bug for that part of this and really pursued it. And I realized if I’m going to do this, I have to invest a lot of money in engine turning machines, so it’s going to have to rise to a professional level. At that point, I took a full three years and focused on refining my skills. I didn’t put out anything until it was at a really high level, not a hobby level.

So, how long has it been now since you’ve been professionally producing watches?

The Infinity series, my own name brand, has only been out for about two and a half years. Before that, I was making dials for other people or a one-off custom watch here and there, and that was for two or three years. So, I guess for about five years I’ve been a professional watchmaker. Where it’s no longer simply a fun hobby. Before all of that, I was simply selling my amateur skeletonized watches for whatever it cost me for the movement and case.

Before your professional work, you weren’t simply modifying a watch, you were still working on a movement and case and dial, and then assembling it all yourself.

I would do all of those things myself. I have a couple of them laying around, but usually keep them hidden so my watch guys don’t make fun of me.

You have to start somewhere. I think it’s cool. So, you then started professionally engine turning dials for master watch and clockmaker, David Walter. Tell me about that.

David is basically like America’s George Daniels. He’s been making clocks for over 40 years and has made some insanely complicated clocks that have sold for hundreds of thousands of dollars. We’re talking clocks with twenty or thirty complications. Before he was a clockmaker, he was a watchmaker at Omega in their complications division. So, he was a master watchmaker and started tinkering with clocks for fun and that just exploded for him. Now he’s gone back to both watches and clocks. He reached out to a friend of mine asking if he could make an engine-turned dial, and that was right at the point where I was getting serious. He connected us together and it’s been a great relationship. I’ve made him a lot of dials, but I’ve really been the one to benefit as I’ve just learned so much from him. So much about machining and watchmaking… Wisdom for the industry, connections… He’s just been a huge mentor.

Do you have any aspirations to make clocks?

No, I don’t think I have any aspirations to make clocks. I’ve talked to him about this, though. I would love to somehow sit down and make a clock with him. Just to learn more from him and have a special clock to hang up in the shop. That would be really special.

You’re currently buying movements, do you have any plans for your own in-house calibres?

Right now, we’re working on a time-only movement in which we’re making everything. Well, let me paraphrase that. We’re making a good chunk of all of the components in the movement. Whatever we’re not making is coming from vintage American movements, so we can say it’s completely American made. We’re also making the case and dial, and we’re working on another tourbillon moonphase.

Will the tourbillon also be in-house?

Oh yeah!

That’s a tough one to make.

Yes. And it’s the same thing, as just about all of the parts will be made right here.

So, you’re currently working on a hand-wound, in-house movement. What other movements are part of the collection now?

The current movement I’m working with now is called the UWD movement – Uhren Werke Dresden. And they’re a company, of course, out of Dresden, Germany. It’s a little complicated. There’s a Tempus Arte group that owns a few different watch companies and that started with Marco Lang. With investors, UWD was going to supply some movements to the industry. They made a fantastic movement, but eventually, sales just weren’t high enough and Lang & Heyne ultimately absorbed UWD. So, now the employees of Lang & Heyne make the UWD movement. It’s still branded as UWD, but it’s the Lang & Heyne employees producing it. It’s just a fantastic movement and I think I’m one of the only people using it.

Does it have a chronometer rating?

No, but it probably could as it’s very accurate. About two to four seconds per day.

Oh ok, so it’s right there. It’s just not officially certified.

Right, exactly.

Looking at your dials, I know a big part of this is the use of meteorite metals. Tell me about the dials and hands, and where you draw inspiration for your designs.

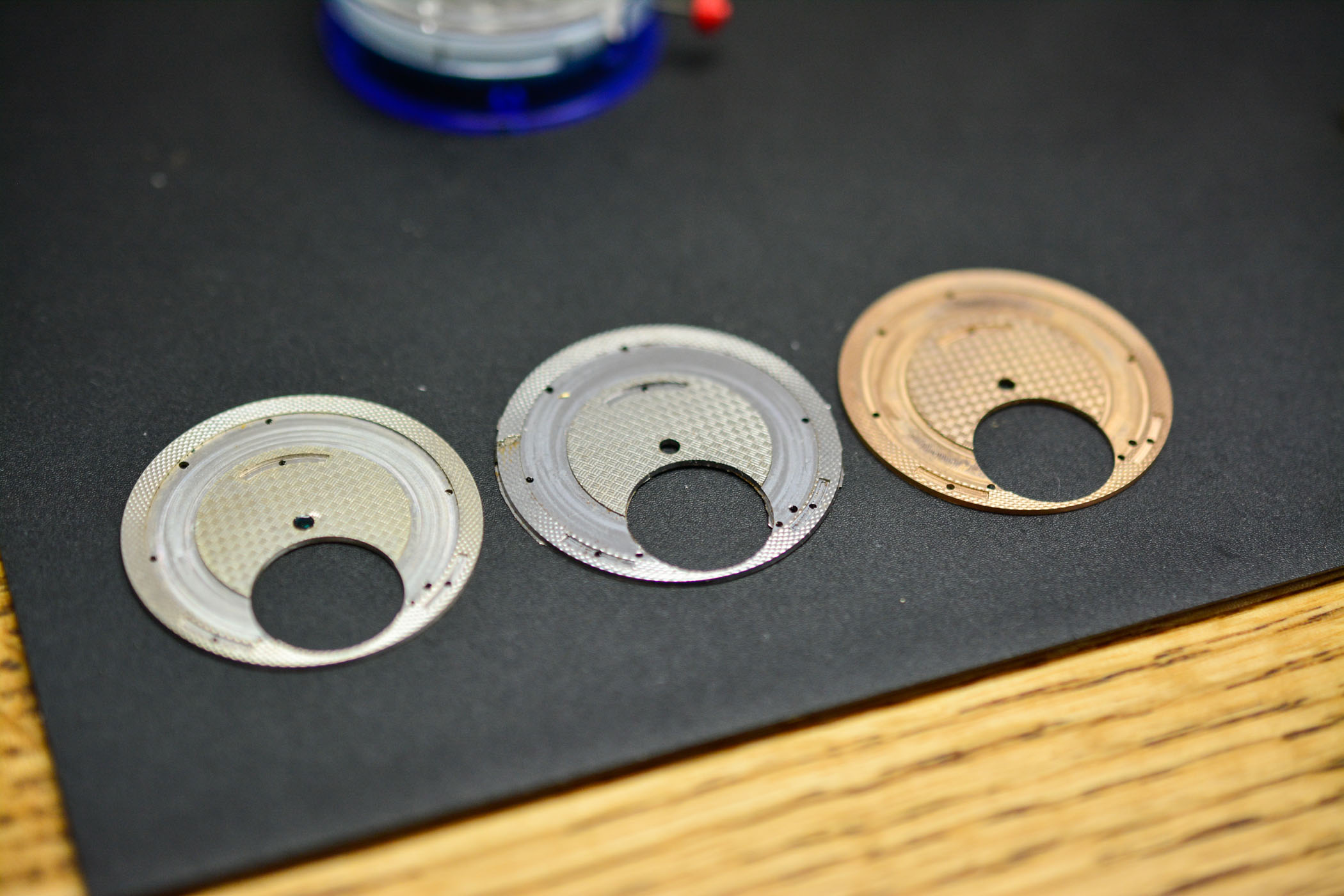

I was really inspired by George Daniels and Breguet and Lépine before them. They all had this really classic aesthetic. I’ve evolved beyond that, but that was the original inspiration. I like very clean engine-turned patterns that aren’t flashy or distracting, like the basket weave and barleycorn. Such classic patterns. They’re intricate and beautiful and detailed, and also help differentiate sectors of the dial, giving a function beyond just form. I was always drawn to that. When I started producing my own line of watches, I realized that I needed to do something new, up the ante and really display the skills I’ve been honing for years. So, I invented this pattern I call the infinity weave, which is a basket weave within a basket weave. I took my normal basket weave, which is already pretty tiny, and then made a pattern that has four tiny baskets within that, which is getting pretty microscopic. The cuts are around the size of human hair. And it’s obviously something meant for this macro age of watch photography and enthusiasts with loupes. When you look at it on your wrist, you see a full pattern, but your eye can’t really distinguish the details of it. But, when you look at it under a loupe, you’re like, “oh my gosh.”

There’s a guy on Instagram, I forget his name, but he does a lot of macro photography.

Atom Moore? Yeah, he’s a good friend of mine. He’s shot some of my watches. So, usually my dials are made out of silver and I do a frosting technique to get this matte white finish, but since then I started experimenting with different metals, different platings. I’ve made some dials with rose gold and also made flame-blued steel dials, and then meteorite. I did a limited series with Collective Horology, they’re a watch club. We did a series of ten with them, which was only available to the club members and it sold out very quickly. Since then, I’ve gotten a ton of orders from all of the publicity from that.

Are you going to eventually give up the work you do with school and focus on this full time?

Yeah, I get that asked a lot. The answer is, I really don’t want to. I like having that balance where a good chunk of my day… Like, now I’m here basically from 8:30 to 4 and then I go to the school from 4 to 6:30. It’s a Jewish school, so the general studies are in the afternoon and that’s what I’m the head of. I’m giving up more and more responsibilities every year, but I really like being there. I helped start the school and have been there for almost ten years, and I like working with high school-aged kids. It’s a million times more stressful than watchmaking or running a watch business. Being an administrator in a high school.

Were you trained as an educator in college?

Yeah, well I got both an undergraduate and Master’s in history, so I never did a formal teacher credential program. I then worked at private high schools. I was also a pole vault coach at a public school for about six years, so I got a lot of teaching experience with that. That was all before watchmaking and marriage and so on. But, really fun years.

Did you ever see this coming back in those days?

Watchmaking… No, not at all. I honestly knew very little about watches back then.

There are very few vertically integrated manufactures in the United States. It looks like you’re about to become the third or fourth main one. You’ve got RGM and Weiss, and not much more.

Yes, it’s very exciting. Hopefully, American watchmaking is going to come back really strong. A lot of people don’t realize how big of a powerhouse we were with American watchmaking.

Oh yes, we had Waltham and Hamilton and Ingersoll…

It was huge. It’s gotten so bad, though. Someone was in Switzerland recently and was with a group of watchmakers in their thirties, watchmakers who were born and lived in an era where American watchmaking has been dead. So, these Swiss watchmakers were telling this person how frustrated they were that they had to ship a lot of watchmaking machines from America. They were so confused. What were these watchmaking machines doing in America? And then they told this guy that they figured it out. The machines must have been in America in the 1960s and 1970s to make guns. They were needed for Vietnam and World War II before that. What else would they use watchmaking machines for? The answer is for watchmaking.

There was over a century of watchmaking in America. And it suddenly just died.

Yes, just imploded. A big part of that was the United States just wasn’t protecting the watchmaking industry. The tariffs were very loose, so the Swiss could easily undercut American watch companies. Also, during World War II, a lot of employees working at these watch companies went into different industries. Aeronautics and such, just tons of new fields were opening up. It’s a combination of these things that killed it. And then, of course, the quartz crisis in the 1960s and 1970s finished it off completely.

Do you know of any other American watchmakers that are up and coming that might be a big deal in the next five years or so?

Oh yeah. Well, first there’s my friend Keaton Myrick in Oregon. He’s pretty far along, already doing a lot in-house. Before Weiss, there was RGM and then Keaton. Weiss has come along and is more into high production, more into mass-producing movements and being more affordable. In the USD 2,000 range. And then there’s a lot of microbrands popping up. There’s DM Tiffany in Arizona doing exciting stuff. Orion Watches make really great watches. There’s definitely a lot happening. What I hope is that American Watchmaking in twenty years will become what Germany and Japan are now. Japan has its mass production of watches. We kind of have that now with companies like Timex, which is still an American-ish company. Same thing with Shinola. A lot of their components are imported. But, Japan also has its really high-end side with Grand Seiko and Credor. And Germany, of course, has a lot of high-end companies as well. That’s where I hope we are in twenty years. I mean, nothing will ever be quite like Switzerland. The watchmaking industry is the industry there. It defines the country. America will never be like that. Germany and Japan have a lot of other industries and then a handful of brands that are on par with the Swiss.

I think that wraps things up. Thanks again Josh, it was great talking with you. Best of luck with the new shop.

Thanks, Erik. It was a pleasure.

More details on J.N. Shapiro Watches, here at www.jnshapirowatches.com.

1 response

Nice to see people with the skill making a living out of watch making. The watch shown reminds me of Roger Smith’s Series 1, which is not a bad thing.