Inside Tudor Watch, Kenissi and the Industrial Ecosystem Behind the Brand

Visiting Tudor and discovering, for the first time, the entire ecosystem behind the brand, including its key industrial partners.

Tudor was founded in 1926 by Hans Wilsdorf, the man who also co-founded Rolex. As such, the brand celebrates its 100th anniversary this year (to be precise, the anniversary was three days ago, on February 17th). To mark this significant milestone, Tudor opened its doors to a select group of journalists, granting rare access not only to its manufacture and its affiliated movement company, Kenissi, but also to a wide range of its component production facilities. Our journey through the brand’s production sites was certainly more transparent than industry practice. We were given access not only to the brand’s own facilities, but also to those of some of their external partners – something that is usually avoided elsewhere… Visiting a brand’s manufacturing sites is often the best way to truly understand it – to grasp the scale of its operations, its approach to quality control, and its philosophy of product design. In this respect, this exclusive opportunity proved particularly revealing. It offered unexpected insights and uncovered aspects of Tudor’s industrial capabilities that are seldom seen – or even known – within the industry.

Before delving into this discovery of Tudor’s industrial platform, it is important to say a few words about Tudor’s trajectory over the past 15 to 20 years. Since 2010, the brand has undergone a significant transformation. It slowly shifted from a company reliant on outsourced movements (Sellita) to one with modern in-house mechanical capabilities, while still keeping prices relatively accessible. The key to understanding Tudor is that it combines Rolex-level industrial discipline with pragmatic engineering choices. Today, the vast majority of Tudor watches are powered by Kenissi movements (more details below), except for two product lines: Clair de Rose and 1926.

The brand’s industrial strategy was instrumental for its take-off and for the rapid development of its activities. Tudor does not communicate any production or sales figures. In their report released just a few days ago, Morgan Stanley and LuxeConsult estimate the brand’s turnover at CHF 480 million, for 180,000 pieces. An underestimated figure in my eyes, this view was reinforced by our visit to Tudor’s industrial facilities. Whatever the exact figure, to give you an idea of the brand’s importance, Tudor would not be far from entering the top 10 Swiss watch brands…

The Tudor Manufacture

Now based in Le Locle, the Tudor manufacture was inaugurated in 2023, leaving its Geneva headquarters (support operations are still based in Les Acacias, adjacent to Rolex’s HQ). It provides a cutting-edge environment for operating the brand’s production activities, namely the assembly of its watches.

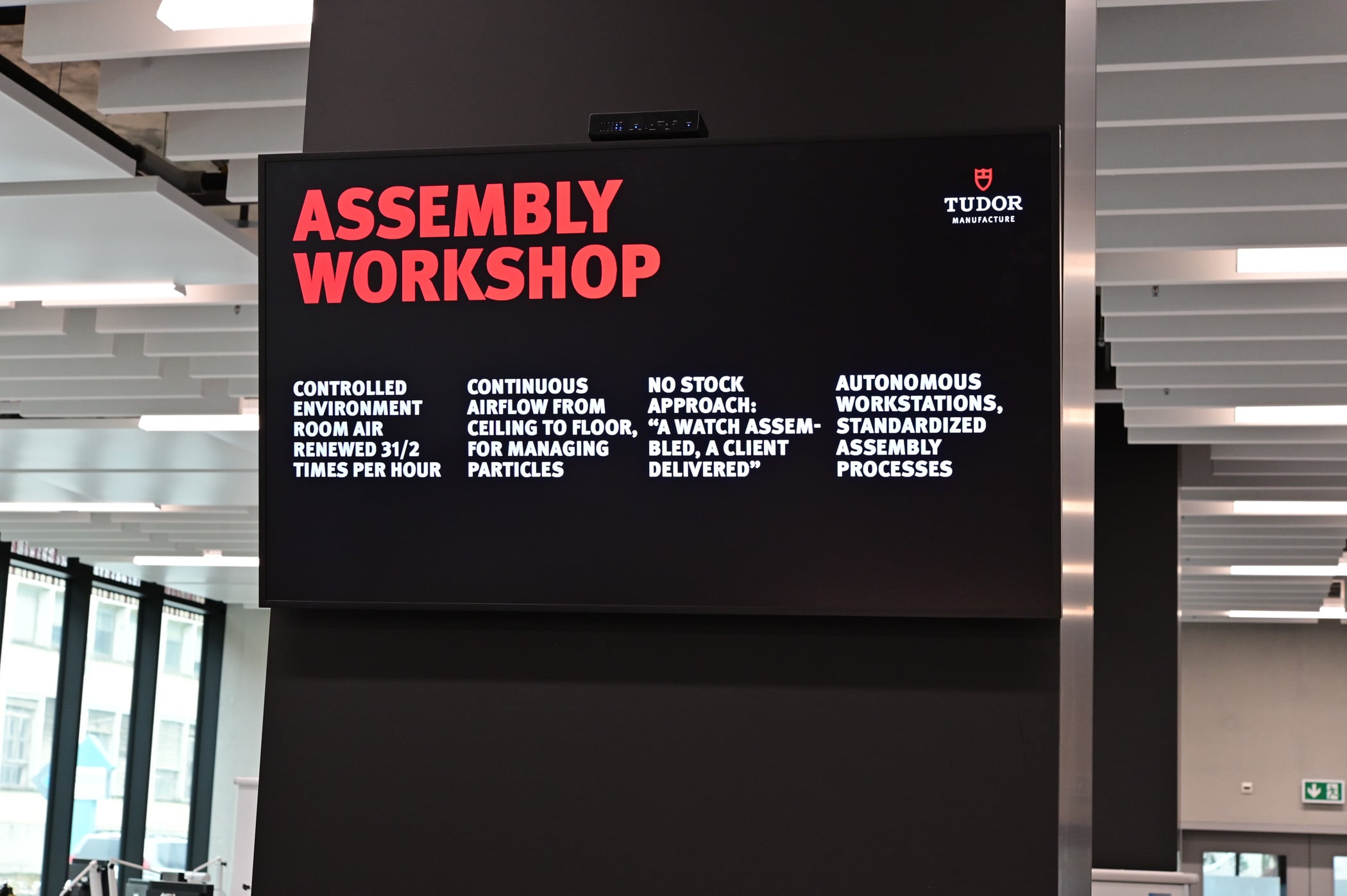

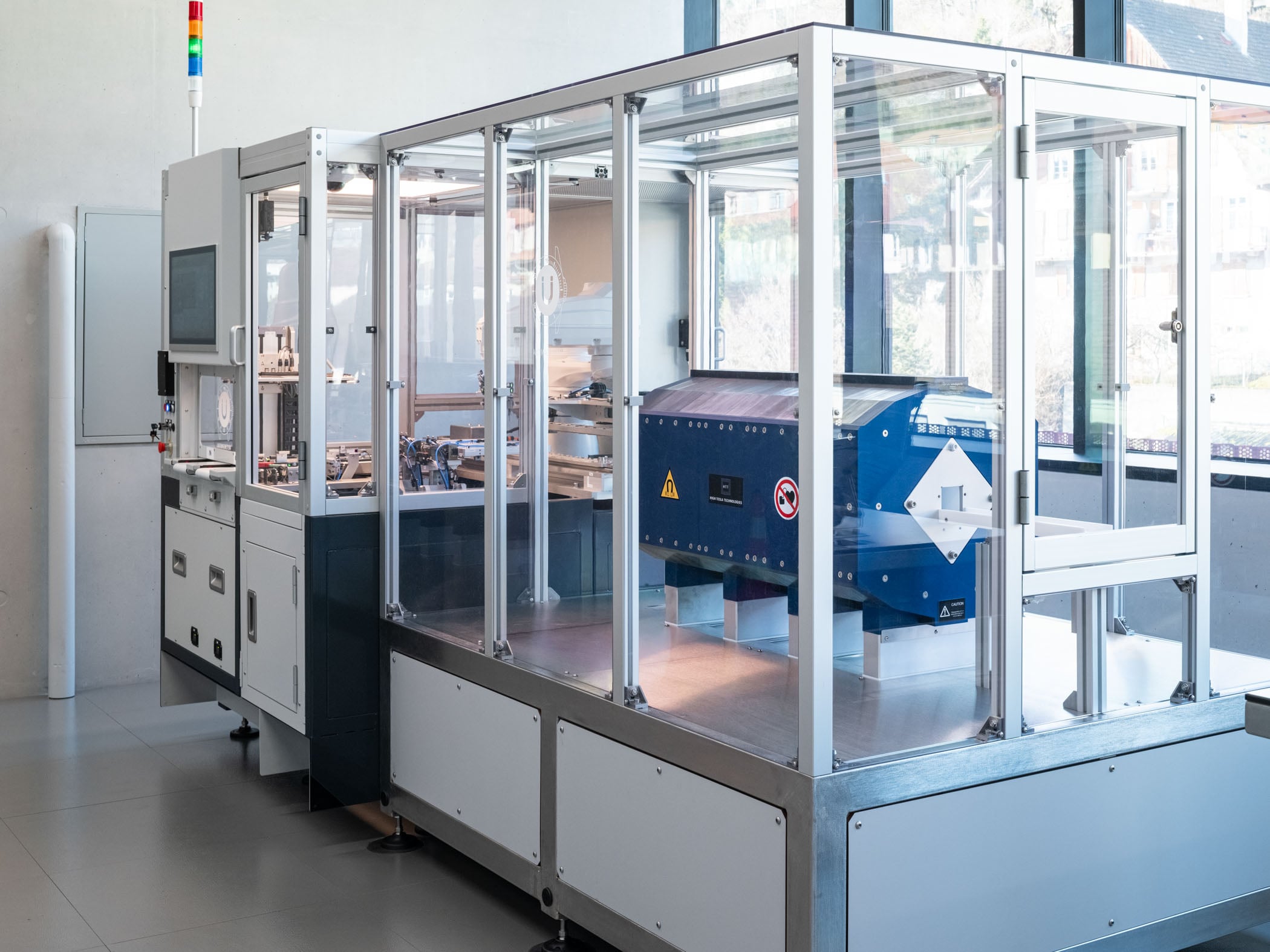

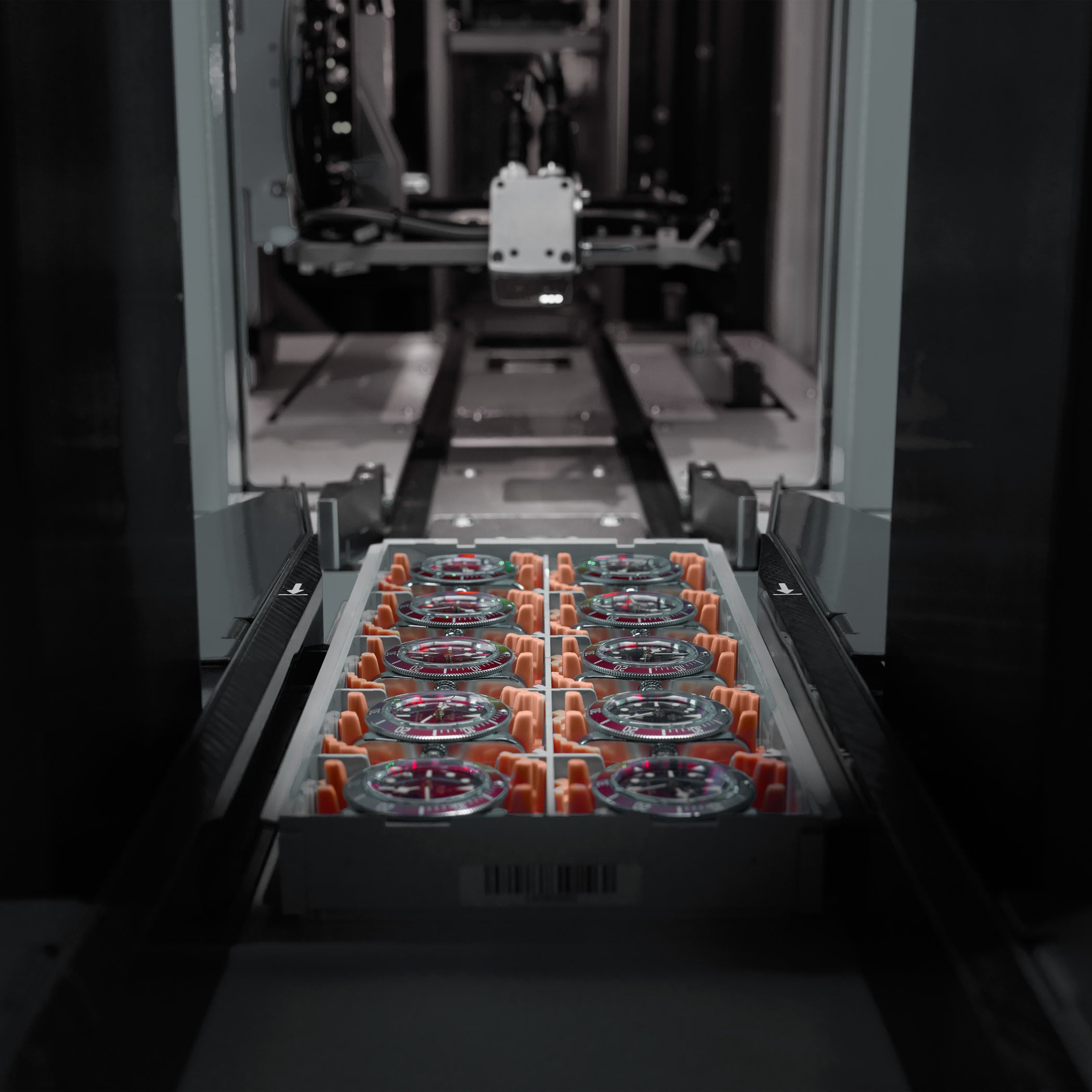

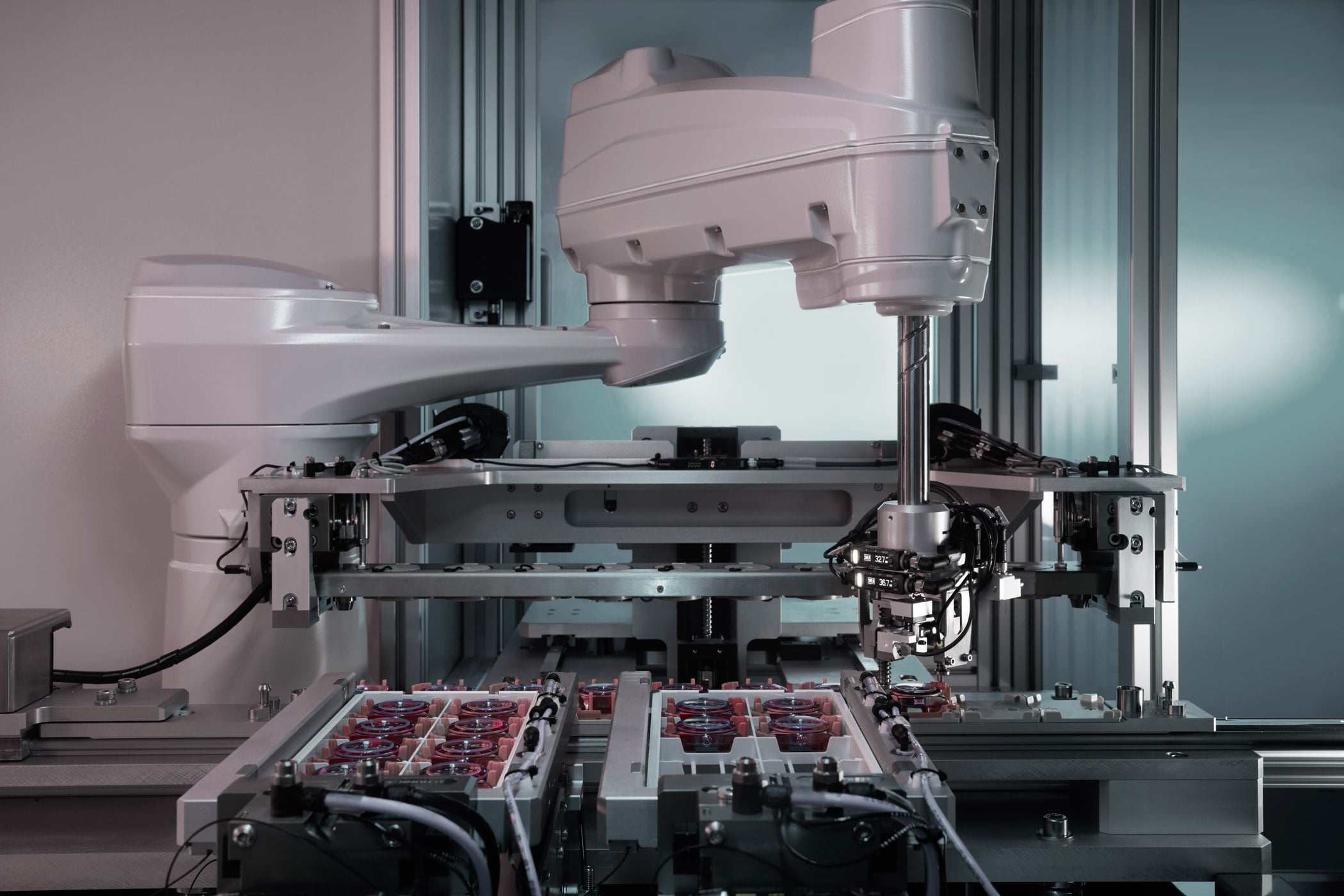

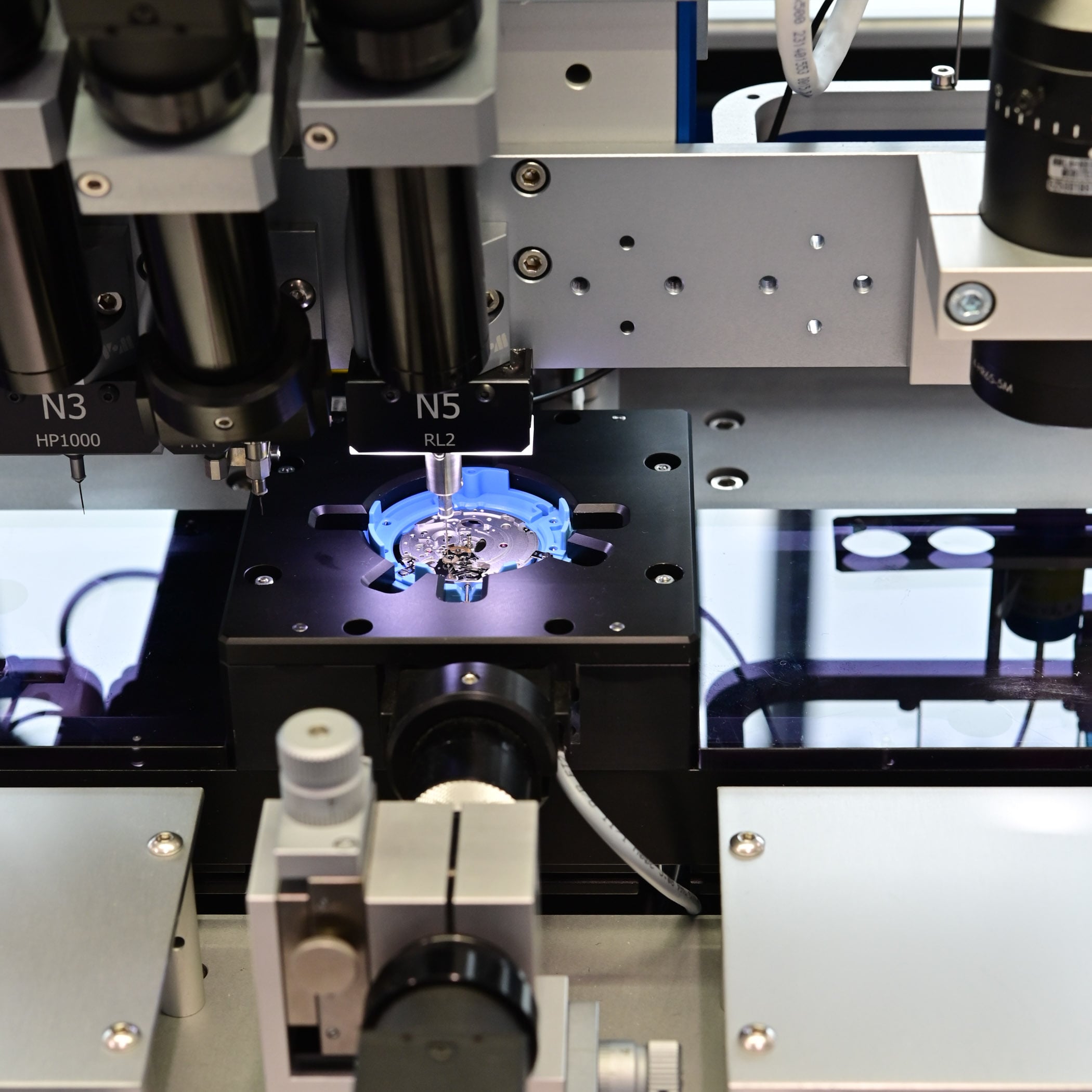

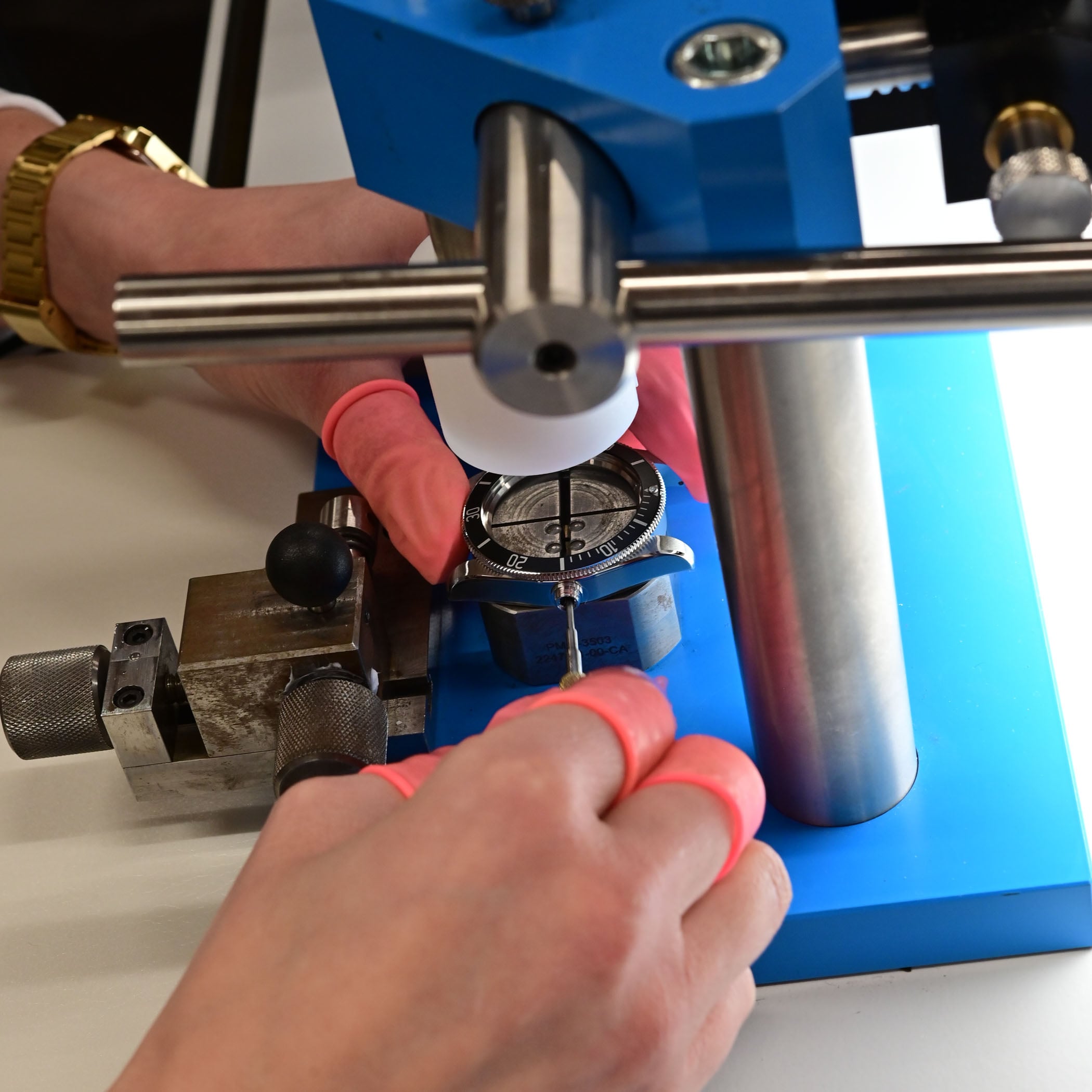

The technology used inside the building is indeed impressive. This is particularly evident in watchmakers’ and operators’ workplaces, where robotic assistance is used at the highest level, as well as in the organisation of workflows and control procedures. The production flow organisation is characteristic of the “Rolex way” with dedicated production cells for each product line, autonomous workstations and standardised assembly processes. It is conducted in a controlled air environment to avoid particles… dust is the worst enemy of a watchmaker… The HVAC system also ensures that the temperature and humidity levels remain stable. Interestingly, production is managed with a “no stock” approach, in which watches are produced only when needed rather than being stored as inventory. The central stock of components is fully automated, with building-wide dispatch to ease production flow.

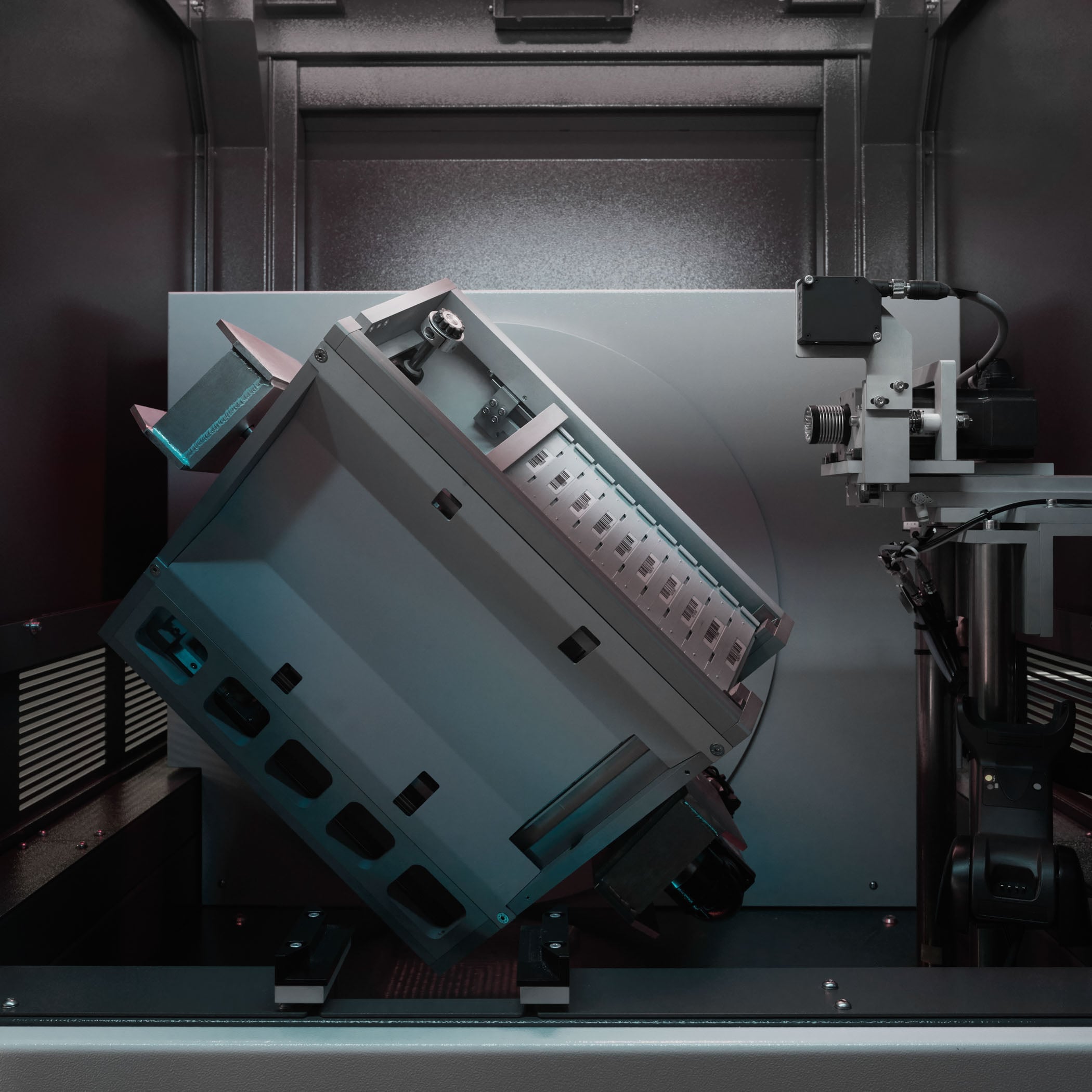

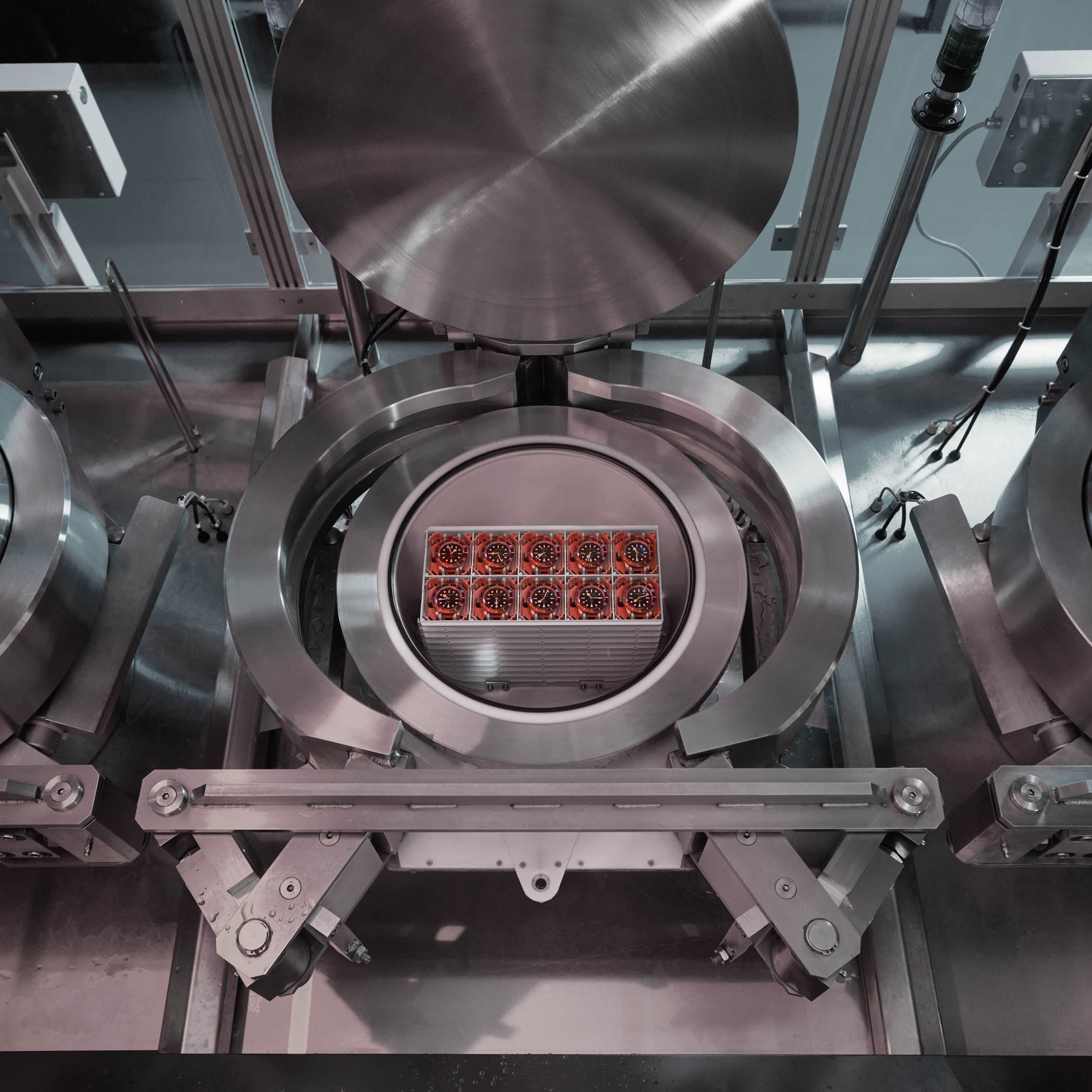

Last but not least, the control management system is truly impressive and also fully automated. A dedicated space in the manufacture called TRC for TUDOR Reliability Control has a futuristic autonomous system that runs 24/7 – robots move across the floor freely day and night, picking up watch heads from one control device and placing them at another! The precision, power reserve, water resistance, and magnetic field resistance are tested. It also includes the Master Chronometer certification for the product line, complying with this demanding certification, in particular with 0 +5 seconds of variation per day (tested on the movement and fully assembled watch), 15,000 gauss magnetic field resistance (tested on the movement and fully assembled watch), waterproofness and power reserve checks.

As said, altogether, the Tudor manufacture is ultra-modern, integrating advanced technological solutions wherever possible. If the human hand remains significantly present, this is not the romanticised image of traditional watchmaking, where a single watchmaker crafts an entire timepiece entirely by hand. At the same time, it is important to understand that this industrial approach is essential for a brand like Tudor, enabling it to produce watches of impeccable quality through absolute precision and repeatability at every stage of production. Rigorous control of each operation is fundamental to ensuring consistency, reliability, and coherence across the entire production. Tudor watches currently come with a 5-year international warranty, and recommended service intervals are between 5 and 10 years.

Kenissi, Movement Productions, and its ecosystem

The result of a research project initiated in 2010, Tudor presented its first proprietary calibre in 2015. In 2016, Kenissi was founded to handle the development and production of Tudor’s movements, as well as those of third-party brands. Chanel became a minority shareholder (20%) in 2018. Besides Tudor, Kenissi supplies (or has supplied) other brands such as Chanel, Breitling, TAG Heuer, Norqain, Fortis, Bell & Ross, Jacob & Co, Ultramarine… The creation of Kenissi specifically serves this purpose – ensuring that these brands are equipped with movements that are not directly Tudor-branded.

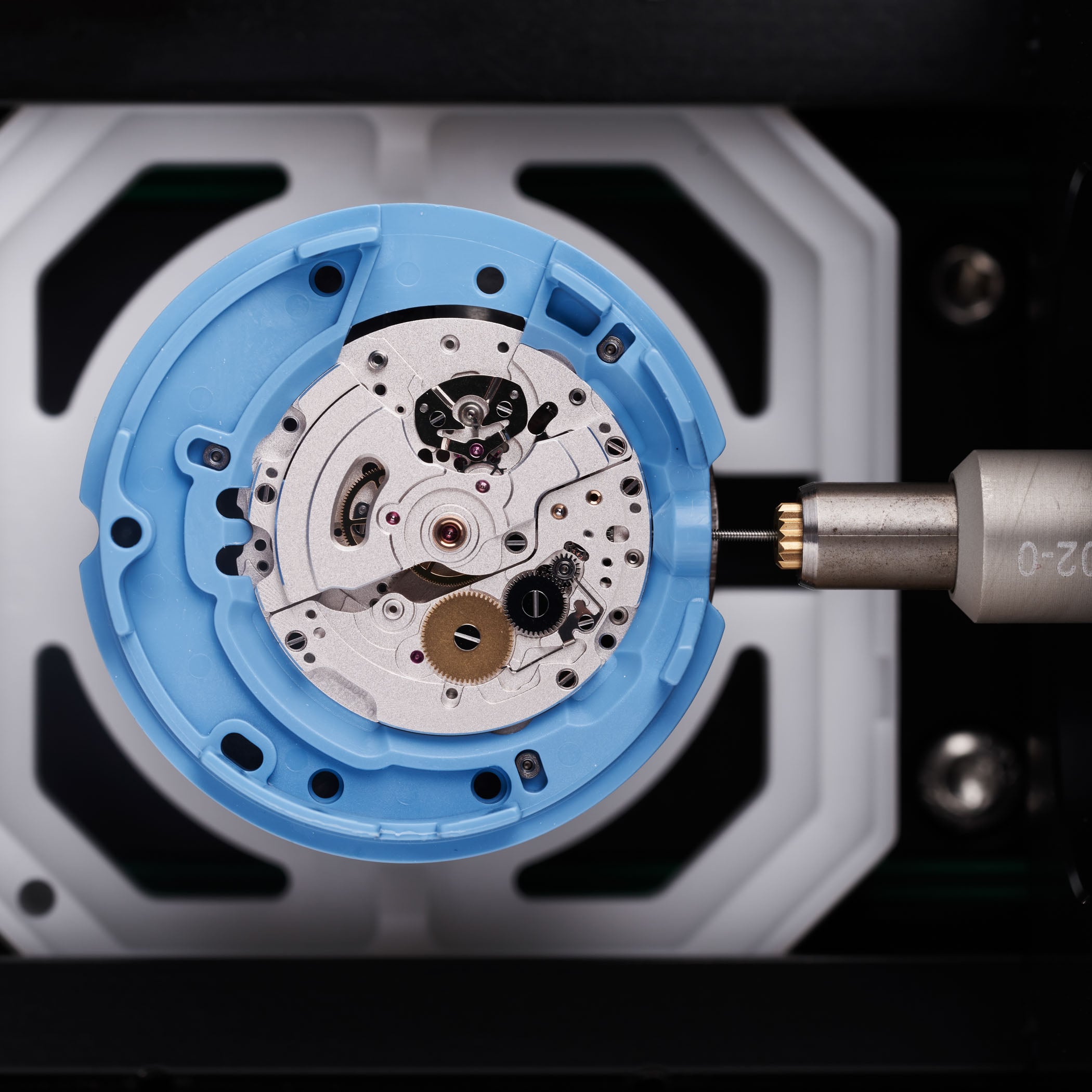

Today, Kenissi is physically and operationally connected to Tudor’s Le Locle manufacture. The company develops and manufactures modern automatic movements with a focus on reliability, robustness, precision and long “weekend proof” power reserves.

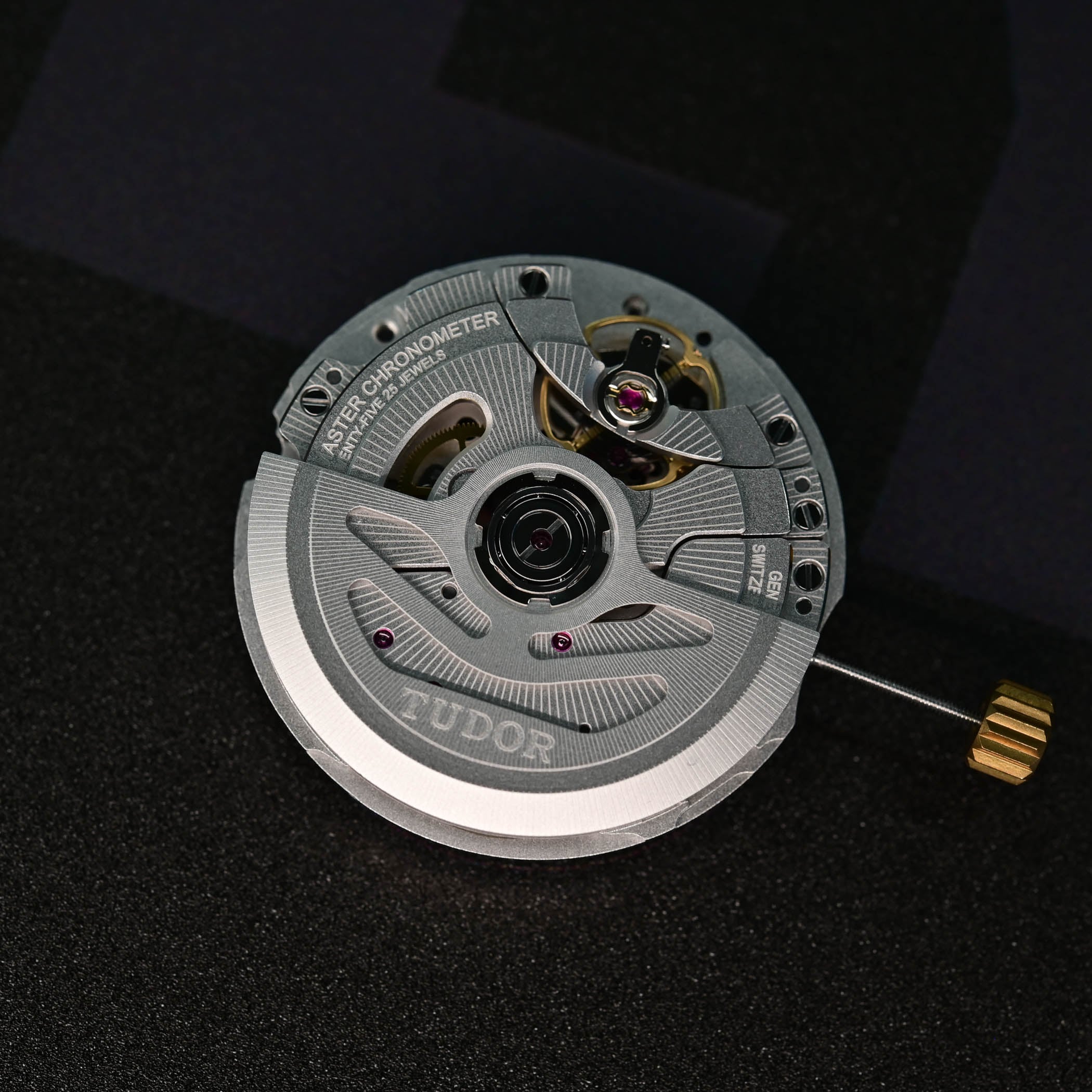

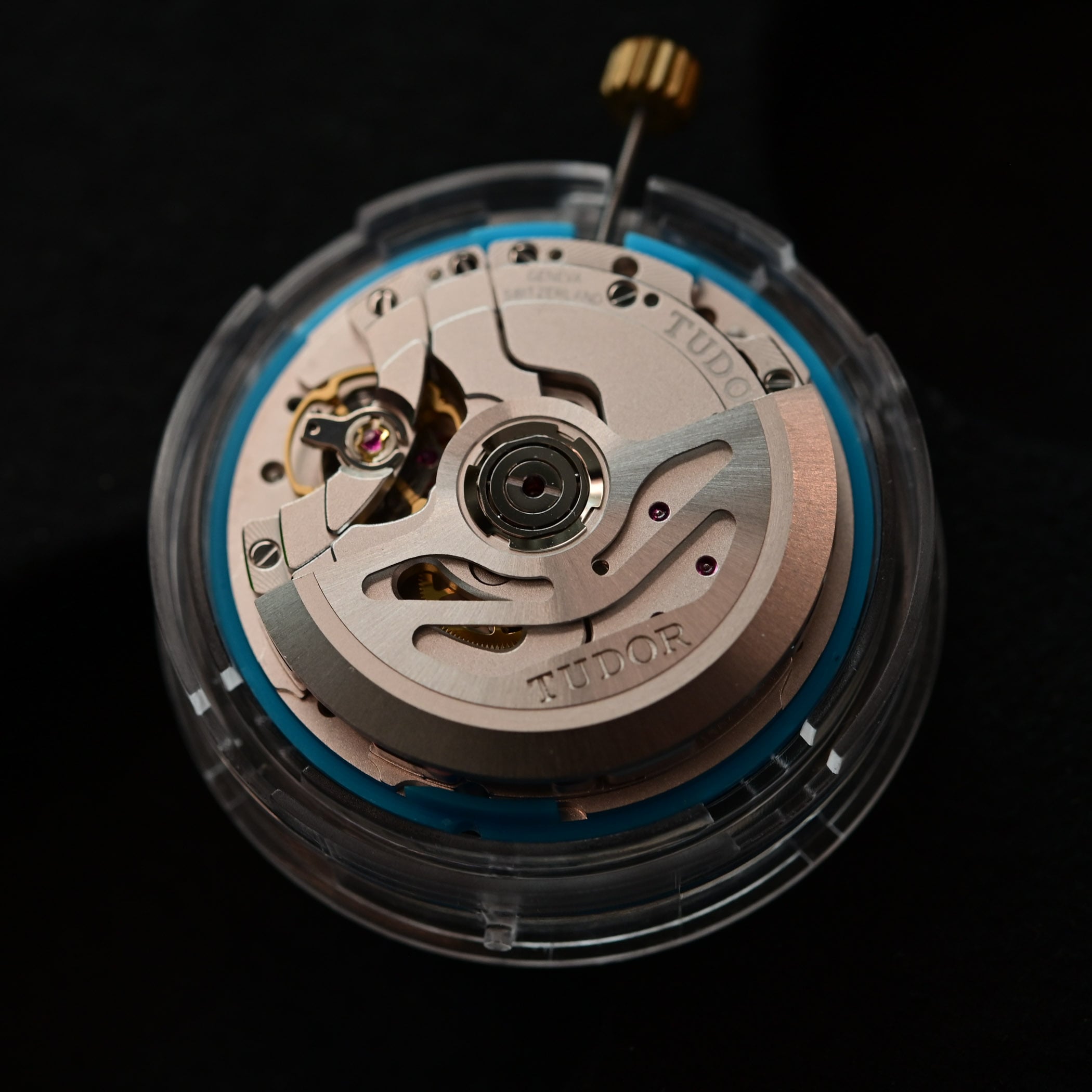

Its product range comprises three families of self-winding movements – large, medium and small size – which can incorporate functions such as a calendar, power reserve indicator or GMT. The calibre 56 is a 30mm movement with 70 hours of power reserve, the calibre 54 a 26mm movement with 70 hours of power reserve and the calibre 52 a smaller 20mm movement with 50 hours of power reserve. From a technical perspective, these calibres all incorporate signature features such as a monobloc rotor in tungsten, a traversing balance bridge or a free-sprung balance – qualitative, tried-and-tested solutions (that are also in use at Rolex).

Kenissi focuses on the manufacturing and assembly of movements at its Le Locle facility, sourcing components from a network of specialised partners. Importantly, over the years, Kenissi established a group of affiliated companies, organised into the Kenissi holding, dedicated to the production of strategic components. EMP manufactures movement blanks, Kenitec oscillators, and Golay-Tec small-stamped movement components.

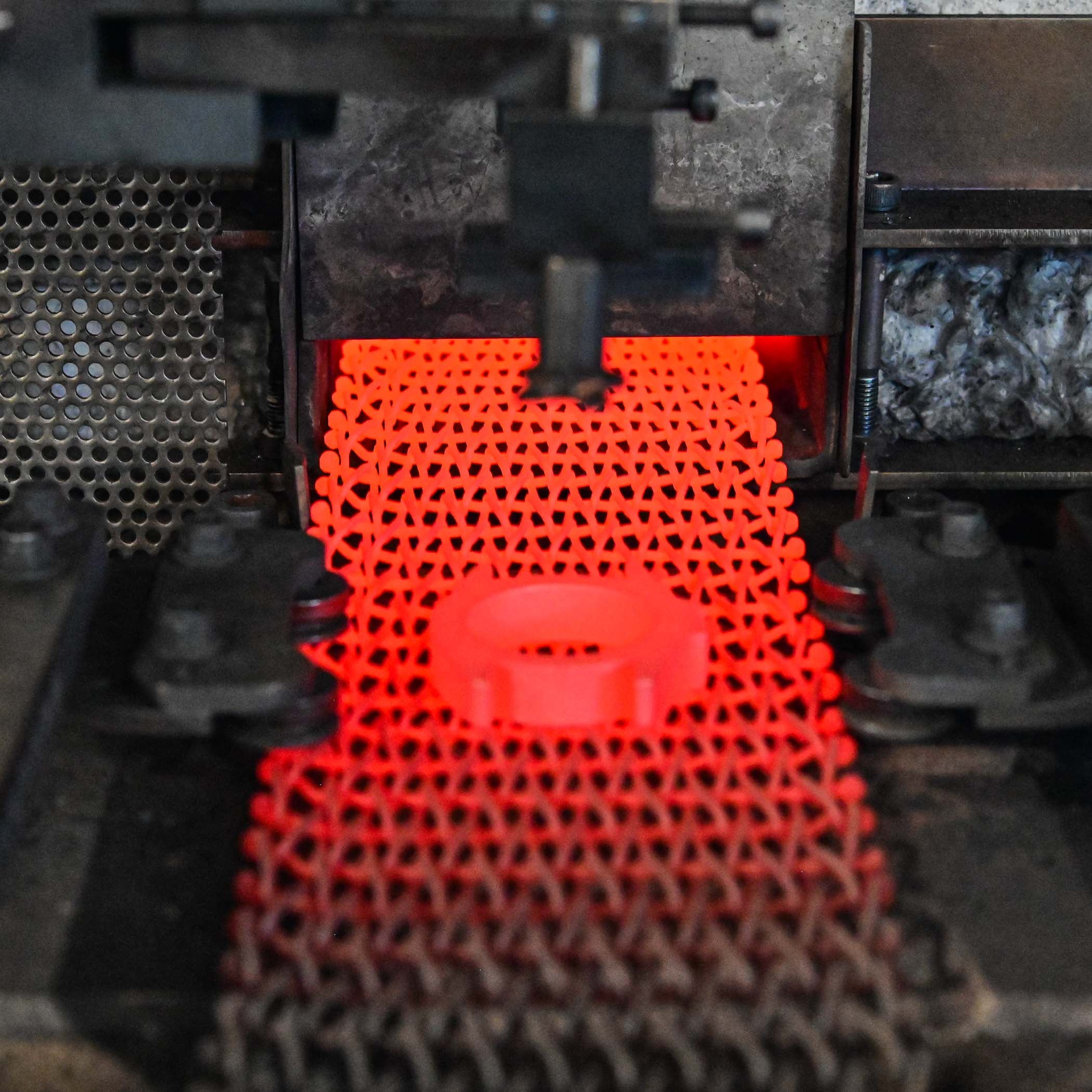

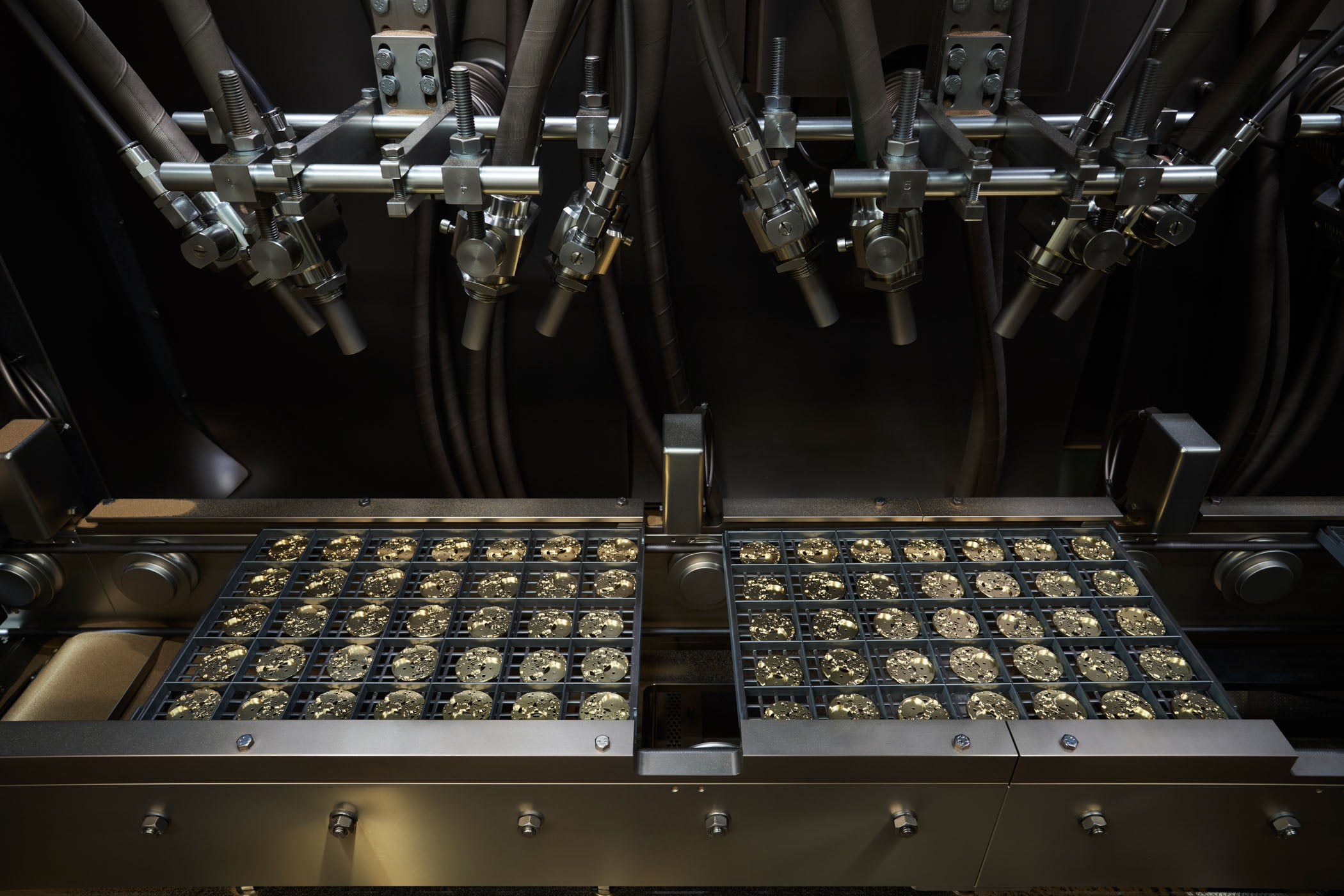

EMP, movement blanks

Kenissi manufactures its movement blanks (the ébauche, meaning the mainplate and the bridges) with EMP – Ébauches Micromécanique Precitrame SA, based in Tramelan in the Swiss Jura. EMP is a major historical manufacturer for this category of components. His founder, Martial Voumard, developed the CNC machine transfer system for movement blanks (the tray or barquettes in French watchmaking jargon).

What was not publicly communicated until today is that over the past few years, Kenissi acquired a majority stake in the company. EMP operates with state-of-the-art production facilities featuring a high-performance machine park designed for quality, large-scale production. Its sister company, Precitrame Machine SA, is the supplier of its ultra-modern machining centres, including rotary transfer machines that offer milling, drilling and tapping in a single clamping. Altogether, the company produces no fewer than 15 million components per year for Kenissi and third parties: barquettes, raw or finished bridges and plates…

Kenitec, oscillator and hairspring production

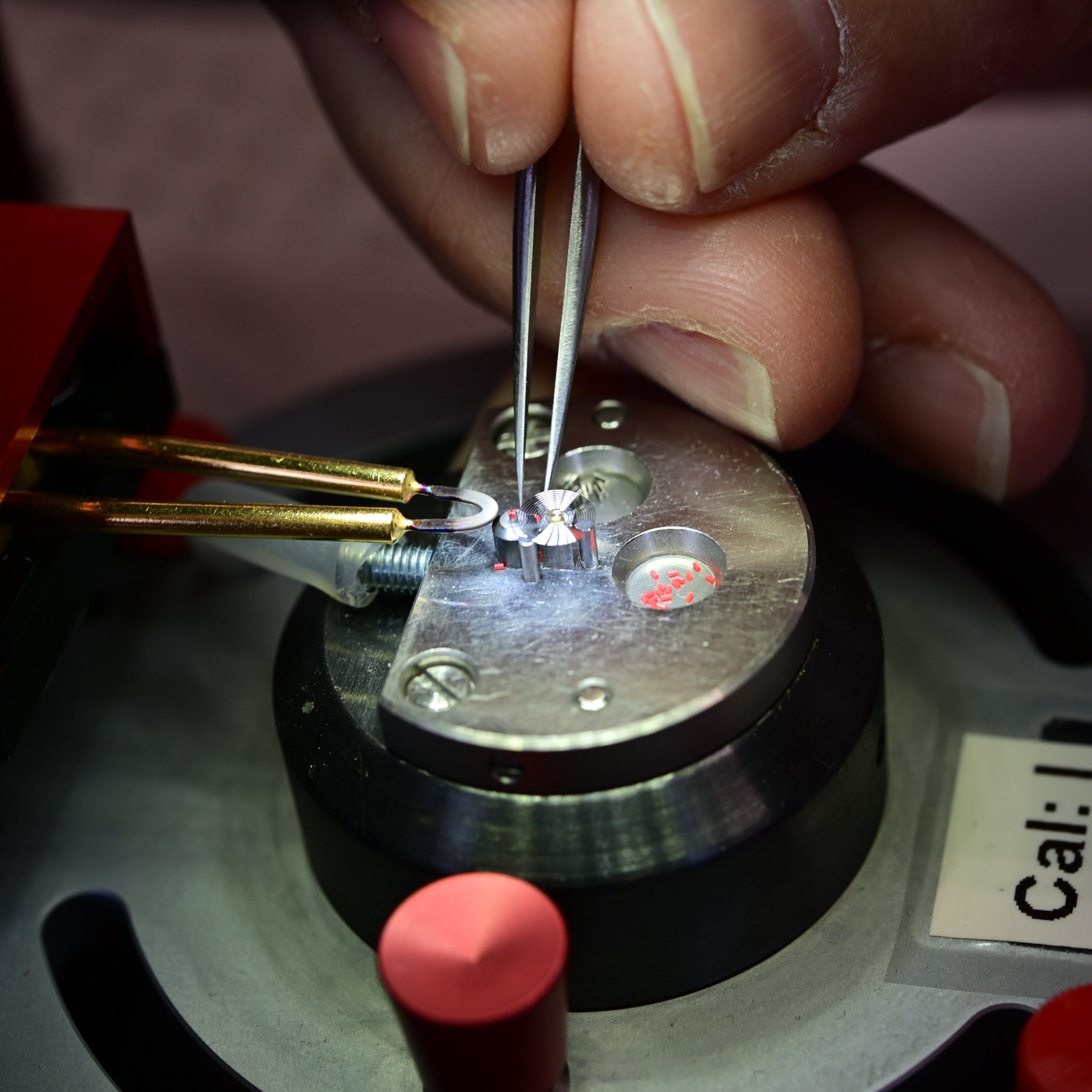

If Kenissi is largely known as the Tudor movement manufacturing company, a fact that is little known in the watch industry and among many enthusiasts, is that Tudor manufactures its own oscillators, including the hairspring. This is particularly significant because very few companies in the watch industry can produce this highly strategic component.

Historically, the dominant producer has been Nivarox, an affiliate of Swatch Group, which long held a near-monopoly in hairspring manufacturing. Rolex, for its part, produces its own hairsprings through a fully independent and vertically integrated operation. Beyond Nivarox, two main companies have recently emerged as significant players in this field: Atokalpa, part of the Sandoz Family Foundation’s watchmaking group, and Precision Engineering, the sister company of H. Moser & Cie.

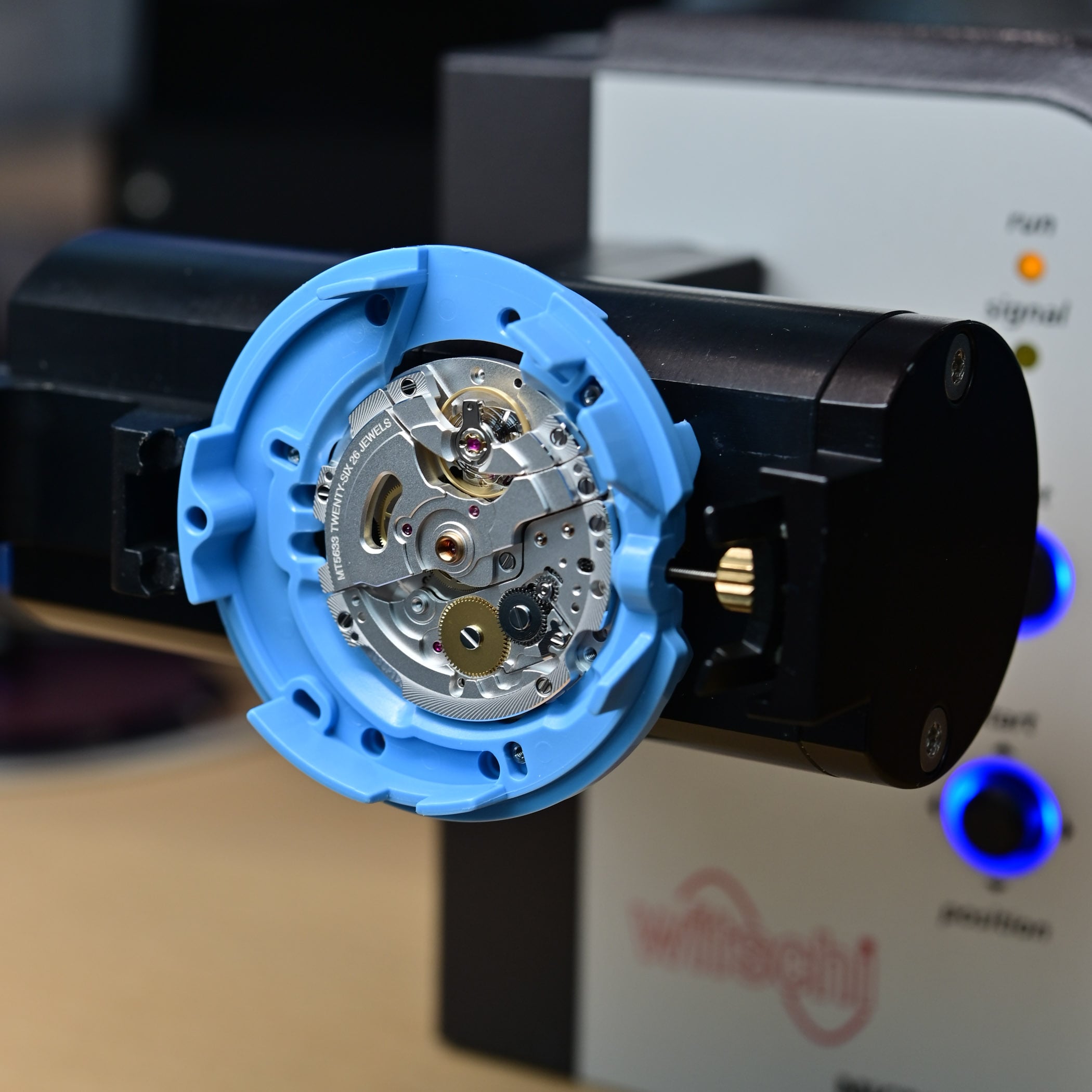

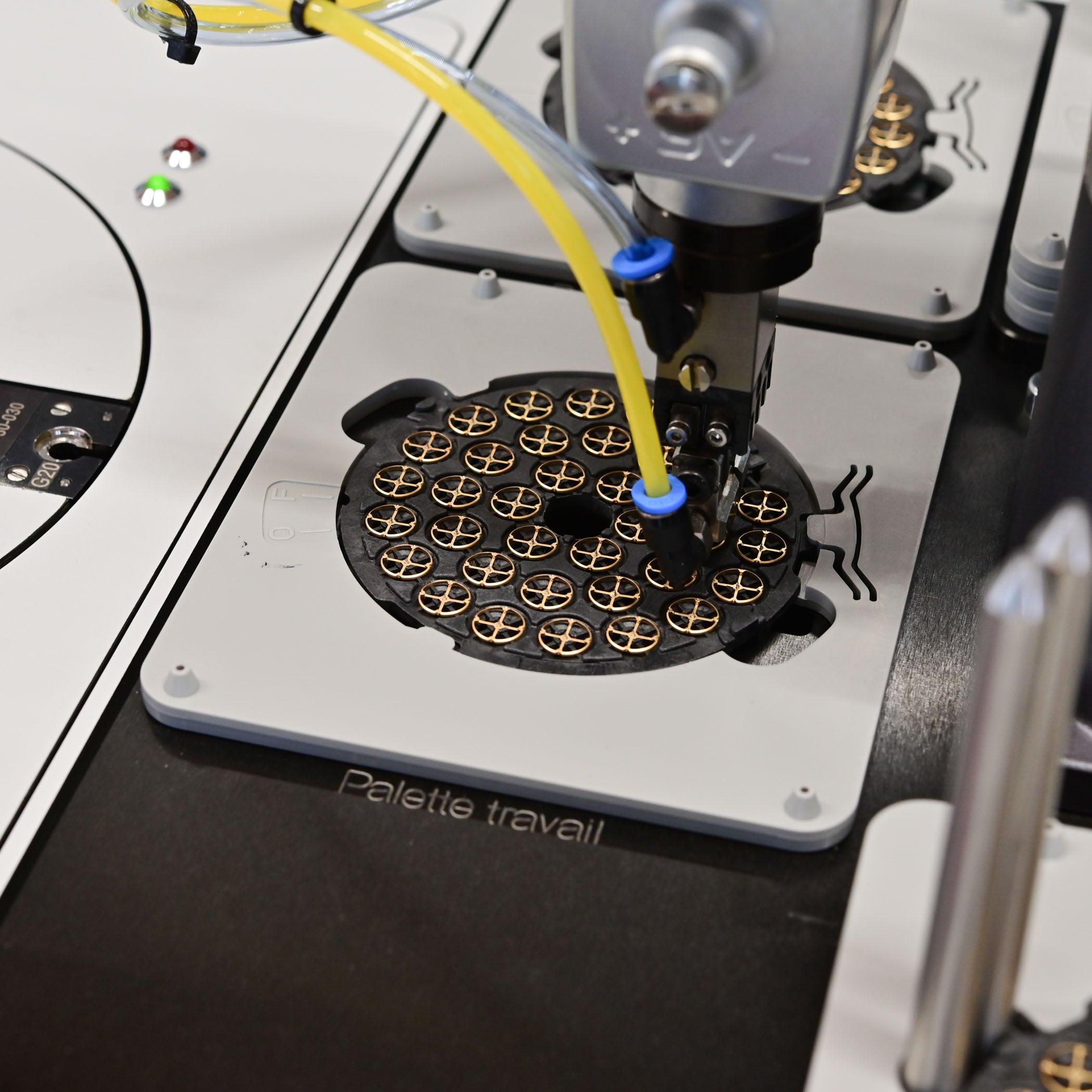

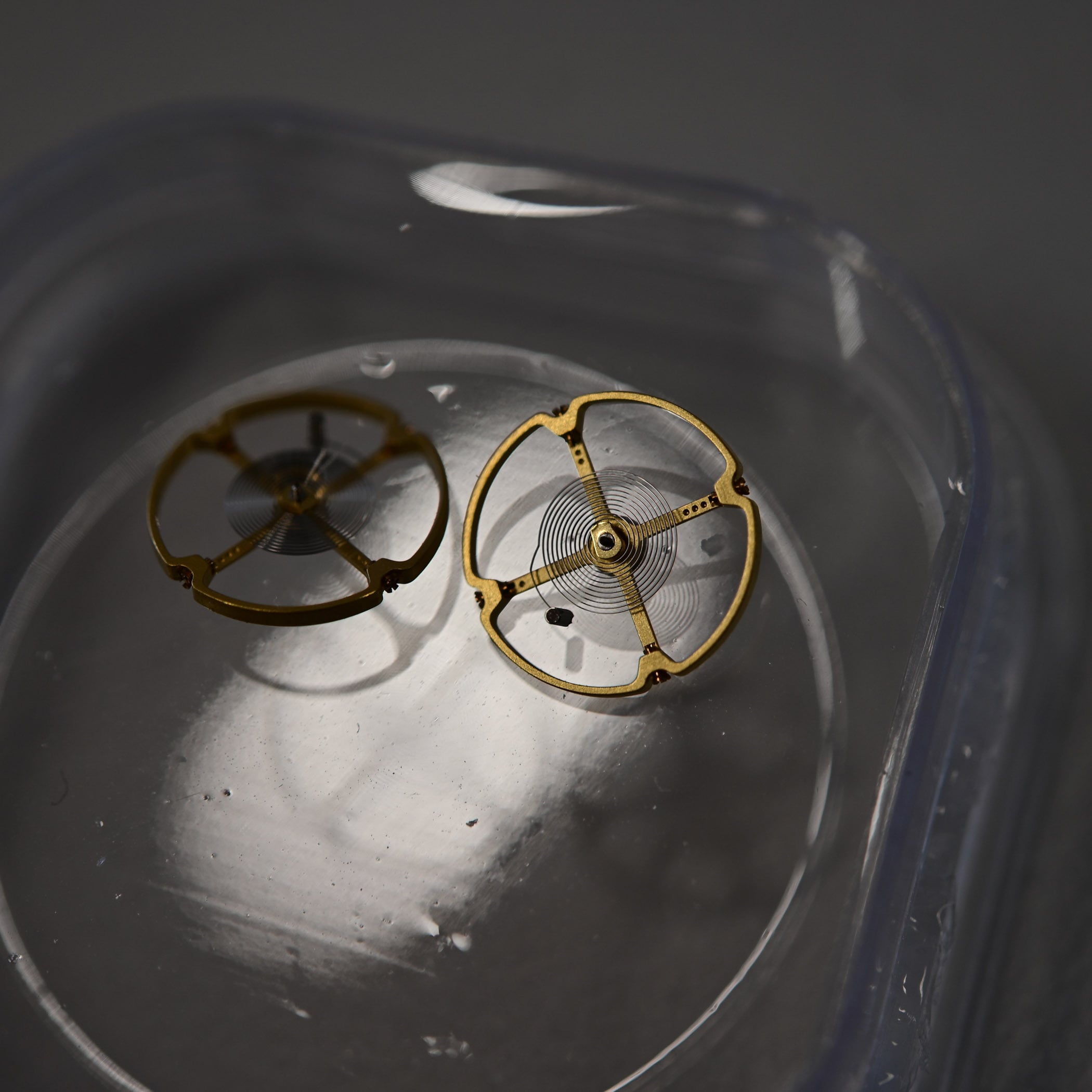

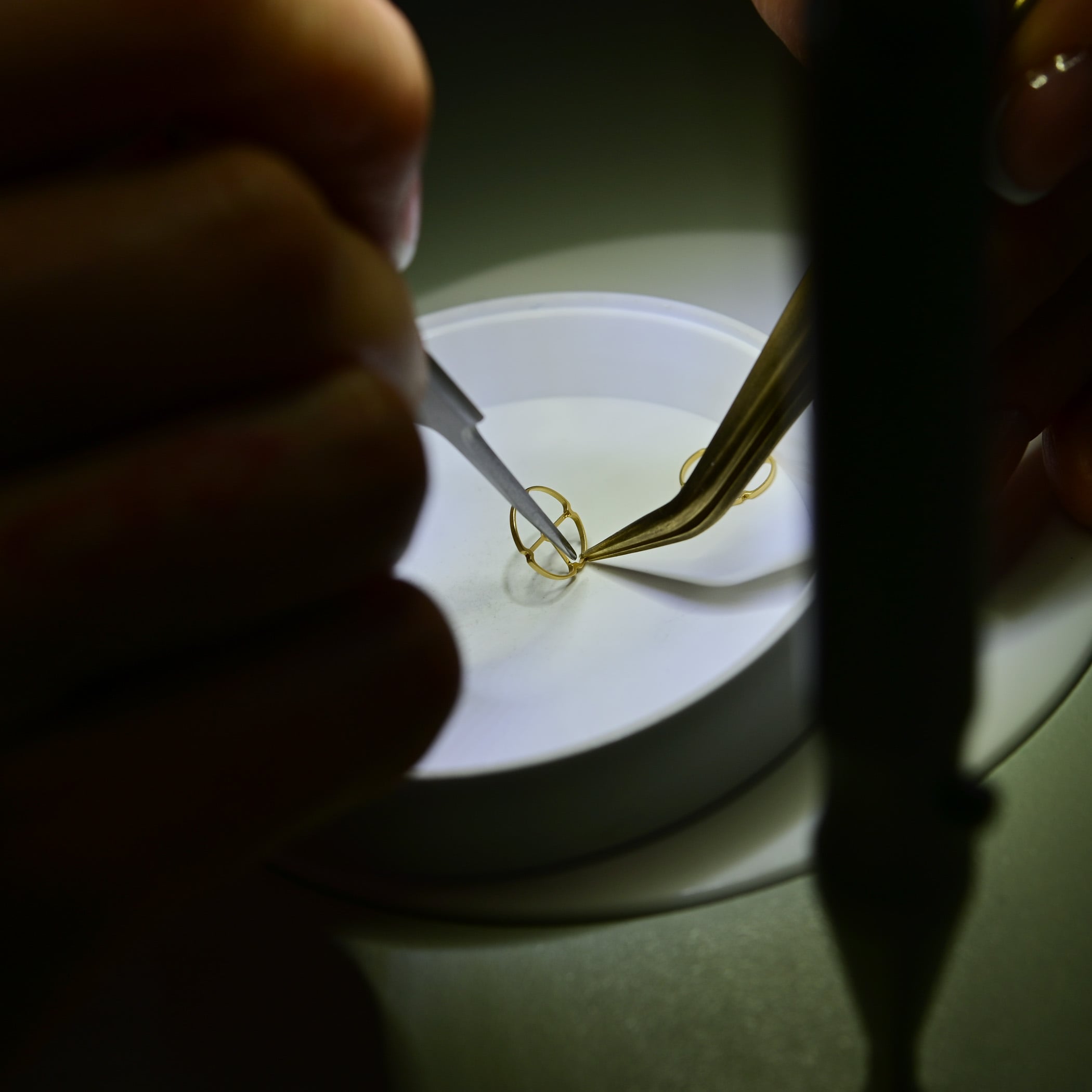

For Tudor, Kenissi established a dedicated company called Kenitec, based in Le Noirmont, to produce its oscillators – i.e. the complete balance wheel and hairspring assembly. The hairsprings are manufactured in-house, covering all production stages from drawing and rolling the alloy to final assembly and fixing to the balance wheel.

From a technical perspective, Kenitec oscillators are fitted with variable inertia balance wheels, meaning they are free-sprung and regulated without a traditional index system. This is a proven, high-quality solution commonly used in high-end watchmaking.

It is also important to note that today, for obvious technical reasons – particularly improved reliability and superior anti-magnetic properties – Tudor uses silicon hairsprings. These silicon components are produced by a specialised external Swiss supplier dedicated to silicon micro-components. Meanwhile, conventional Nivarox-type alloy hairsprings are manufactured by Kenitec for third-party brands supplied with Kenissi movements.

The reason for this distinction is straightforward: access to silicon hairspring technology is protected by patents, those held by the consortium that includes Patek Philippe, the Swatch Group, and Rolex. As an affiliated brand of Rolex, Tudor benefits from access to this patented technology. However, it cannot be extended to third-party brands. Silicon hairsprings are therefore reserved for Tudor within the Kenissi ecosystem.

External Components and strategic partners

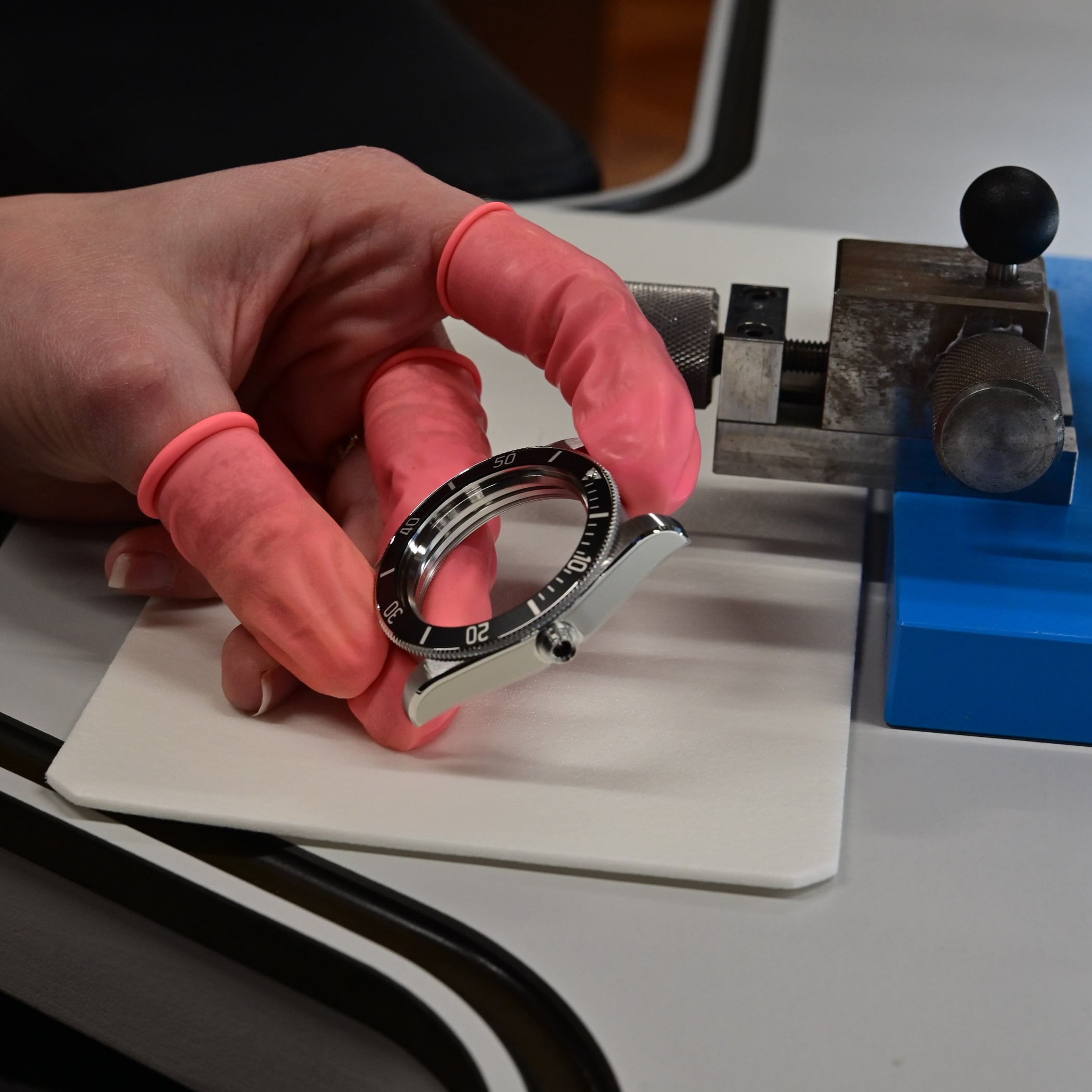

Alongside the ecosystem linked to the movements we just discussed, Tudor has also identified strategic partners for all external components (the habillage in French watchmaking jargon). We had the opportunity to visit several suppliers in this field:

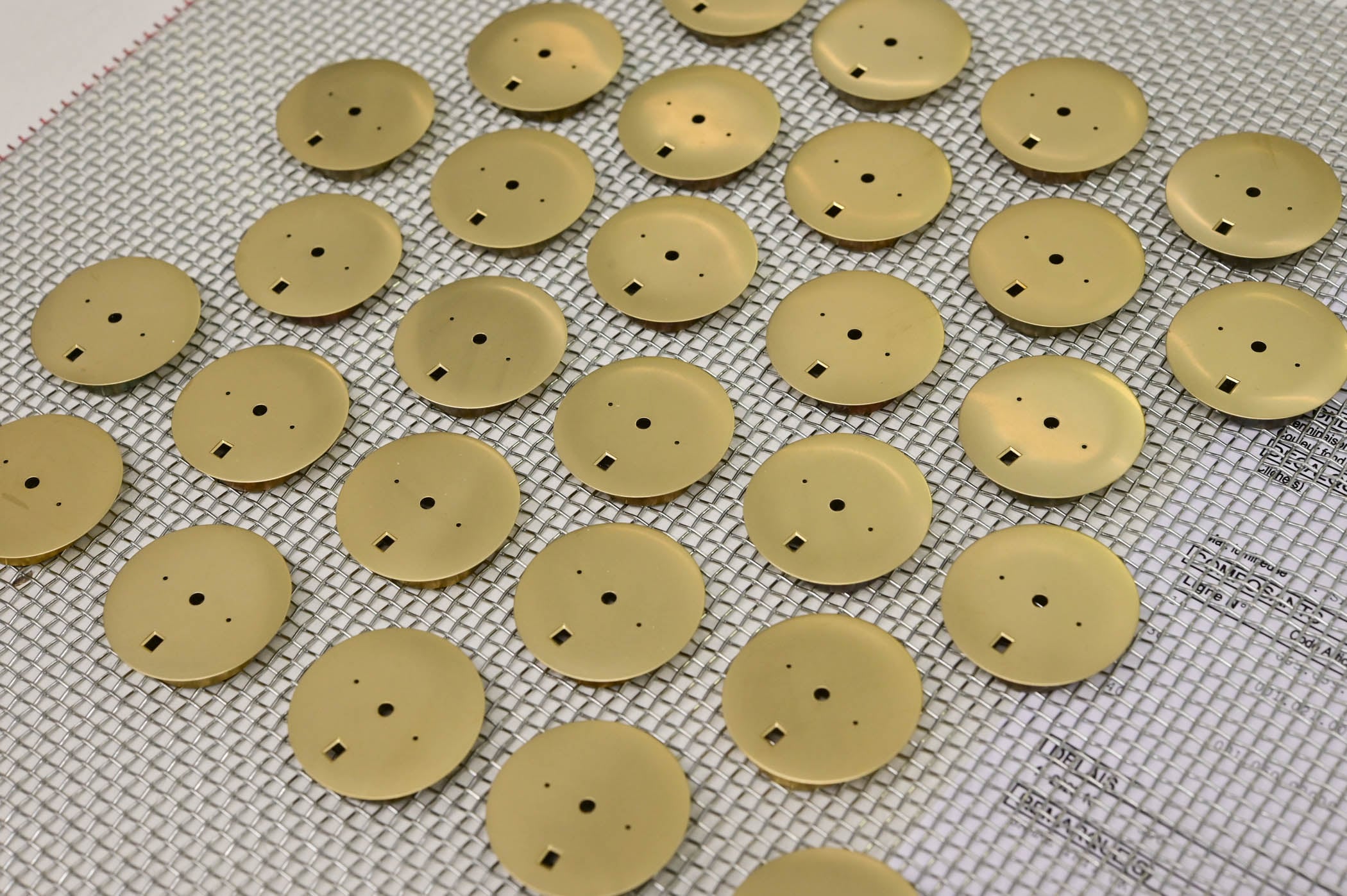

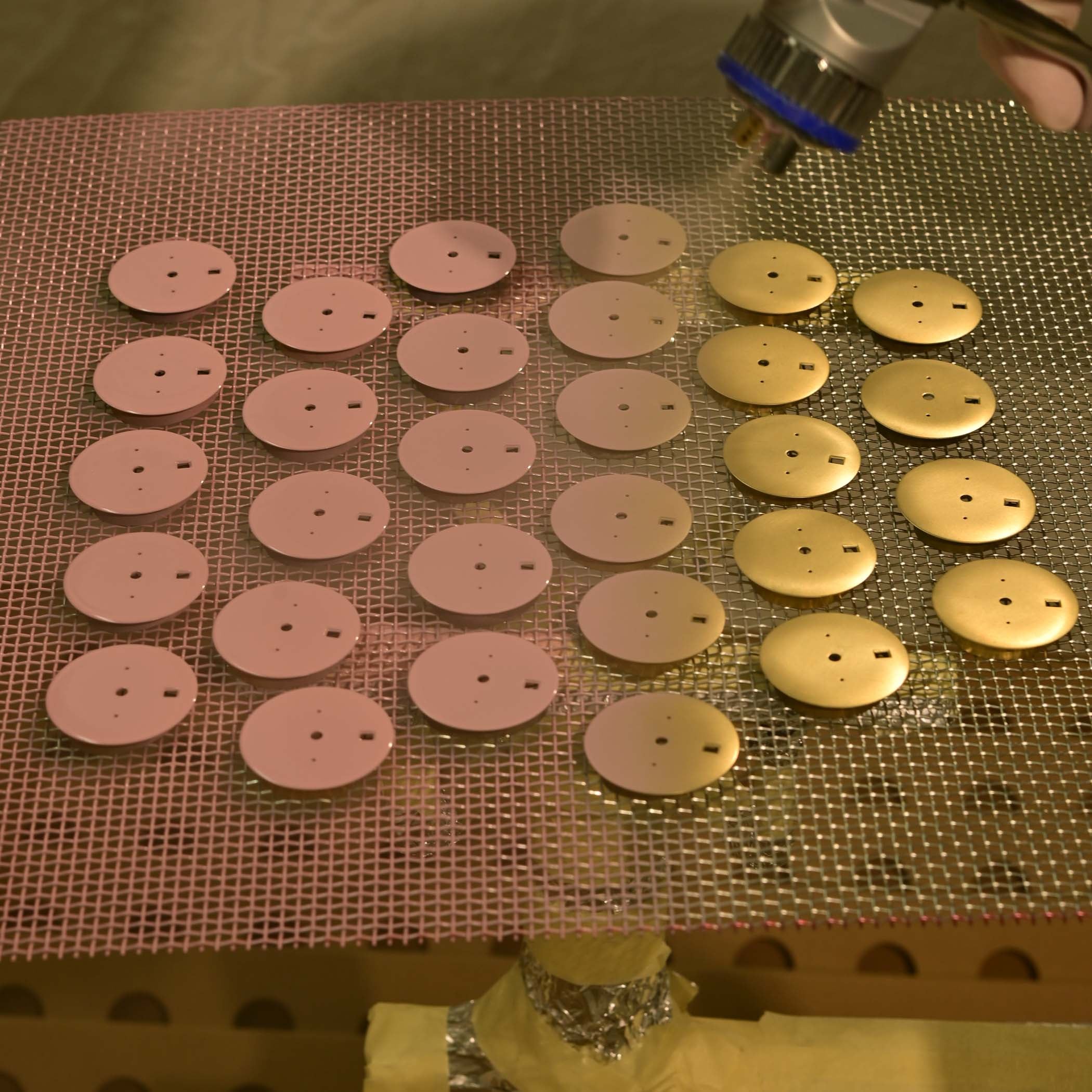

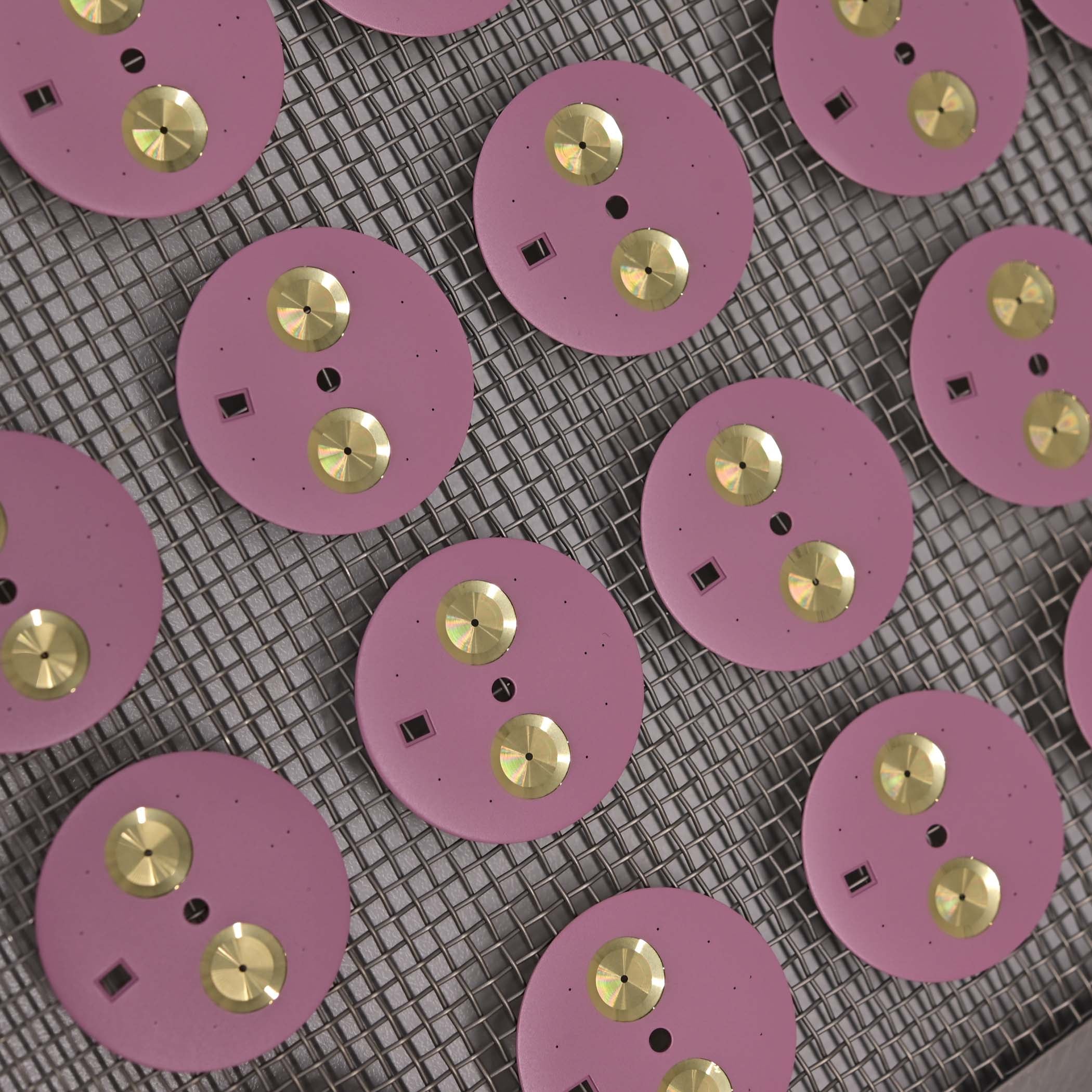

- Montremo in La Chaux-de-Fonds, which manufactures dials

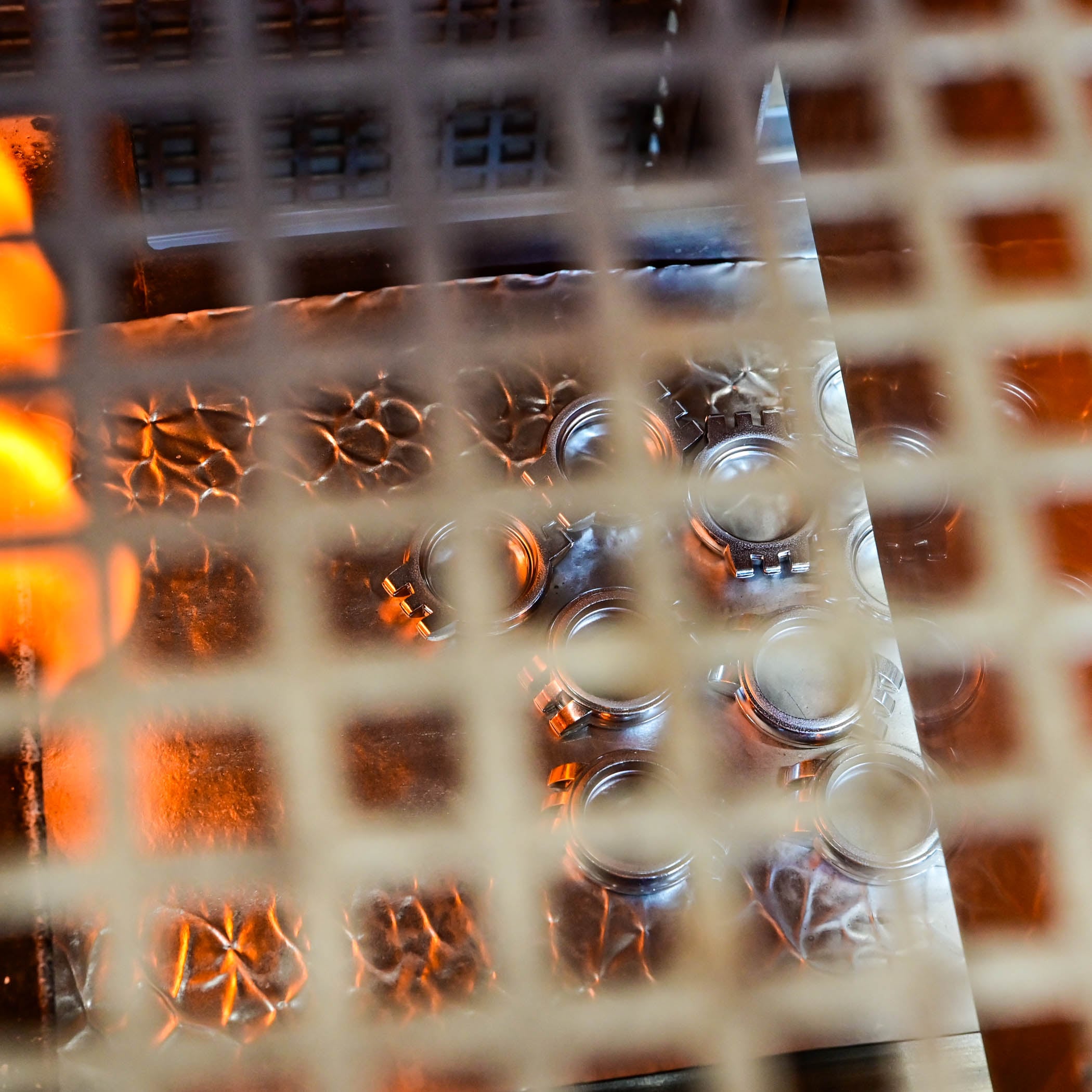

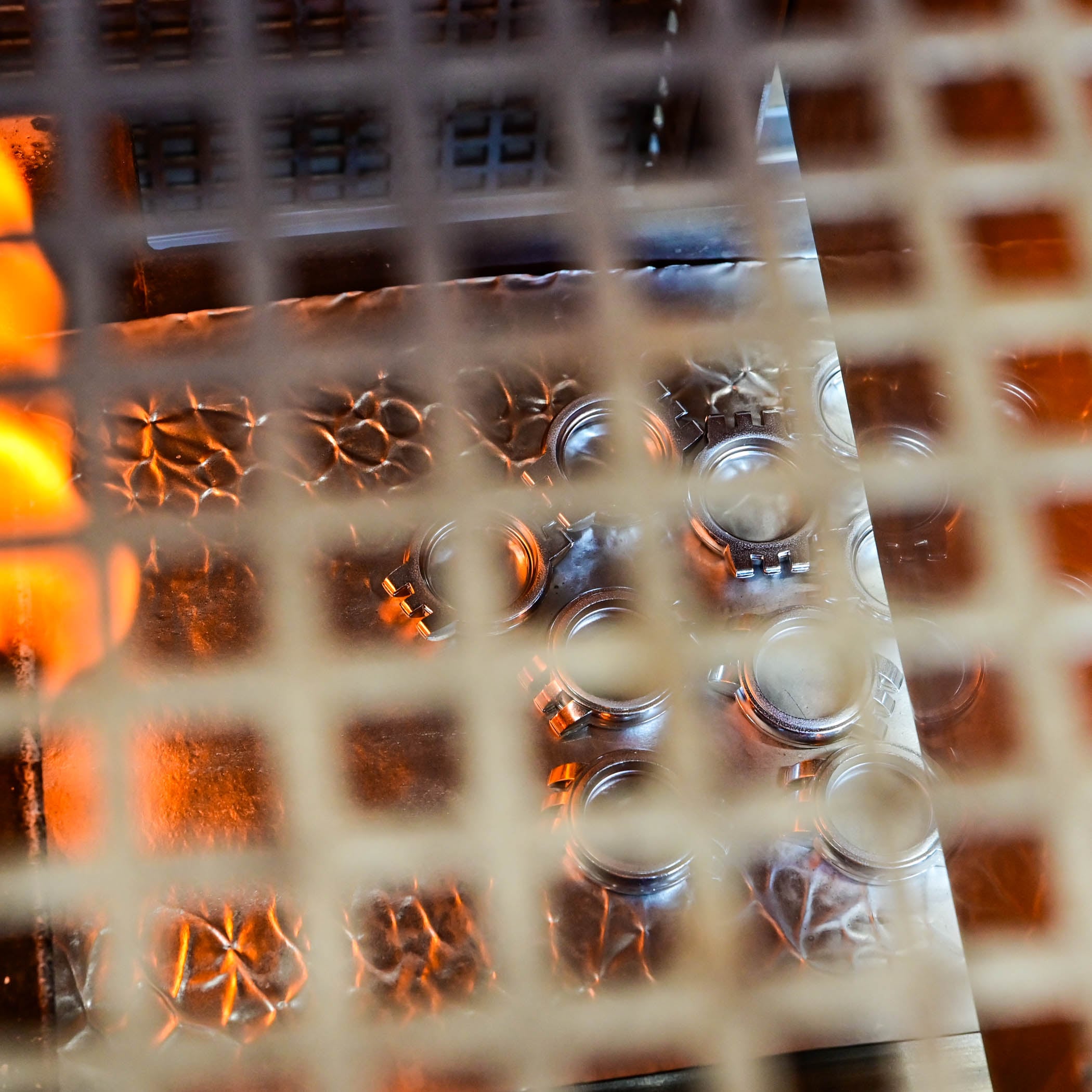

- Joseph Baume in Le Noirmont, responsible for producing watch case blanks

- Orolux in Le Noirmont, which manufactures watch cases

- Detech, a company specialising in bar milling and screw machining, which produces components for Tudor bracelets and clasps

These visits allowed us to discover suppliers who work with different brands in the watch industry but have built particularly strong partnerships with Tudor. Each of them showcases state-of-the-art, ultra-modern industrial facilities, fully aligned with Tudor’s quality standards. Their technical capabilities, precision engineering, and advanced production processes clearly reflect the level required to meet Tudor’s expectations.

Uniquely Tudor

When people think of Tudor, they often also think of its sister company, Rolex, part of the Hans Wildorf Foundation. The Crown is a world apart within the watch industry. It is apart culturally, but also for its distinct organisation and deep industrial integration. In addition, Rolex maintains a culture of confidentiality, meaning certain aspects of its operations and activities remain little known to the public. It operates several watchmaking and production sites and maintains a vertically integrated manufacturing ecosystem that covers nearly every component of a watch. From cases to bracelets to high-precision movement parts, Rolex operates with unique autonomy – even while collaborating with selected external suppliers where it makes sense. This industrial philosophy is part of what has defined Rolex’s reputation for consistency and technical control.

What is surprising, then, is how specific the industrial model is at Tudor, despite the shared heritage and culture. Unlike some watch groups that centralise production resources or pool strategic components across brands, Tudor operates with a largely independent manufacturing structure. There is no broad industrial synergy in the sense of shared production lines for key components. One might expect overlaps in areas such as movement, manufacturing or regulating organs, but Tudor’s approach is intentionally distinct. Its production flows are organised around its own operational and technical logic. These are pragmatically aligned with the brand’s market positioning and the scale of its business.

As with Rolex, quality is a major concern. Tudor’s industrial model is built around stringent quality standards that align with modern, high-performance watchmaking. Certain Tudor watches, for example, meet the demanding Master Chronometer certification. Originally developed by Omega in collaboration with METAS, this certification evaluates precision, magnetic resistance (to 15,000 Gauss), and overall performance under real-world conditions, underscoring Tudor’s commitment to measurable excellence.

All of this highlights a key point: while Tudor and Rolex share philosophical roots – including a focus on durability, reliability, and purposeful design – they are separate industrial entities. At times, product typologies may echo a common heritage, but a Tudor is a Tudor, just as a Rolex remains a Rolex. Each brand intentionally expresses its identity through its own industrial model. Eventually, some of the solutions that have already been tried and successfully implemented in one company will be adopted and applied by the other, but in its own manner.

For more details, please visit tudorwatch.com.