How Are Mechanical Watches Wound? A Comprehensive Guide to Automatic and Manual Movements

Mechanical watches are powered by a mainspring, but that can be wound in a surprising number of ways.

There are basically two types of watch movements – mechanical and quartz. The latter is powered by a battery or a combination of solar and rechargeable cells, while the former is powered by one or sometimes multiple mainsprings with no electrical input. There are also grey areas like Grand Seiko’s Spring Drive or Accutron’s Electrostatic calibre, but those are rare exceptions. Mechanical movements themselves fall into two categories, hand-wound and automatic, and both can be wound in a variety of ways. Let’s take a look at the many and even bizarre ways a mainspring can be wound within a mechanical watch.

The crown

The most common way to wind any mechanical watch is via the crown, usually positioned at 3 o’clock. In more unusual cases, it can be at 2, 4, 12 or even 9 o’clock, but simply turning the crown (usually) clockwise will wind the mainspring, regardless of placement or if it’s hand-wound or automatic. A handful of entry-level automatic movements like Seiko’s 7S26, however, can’t be hand-wound by the crown and rely solely on the rotor for winding. If it stops, you just have to shake it for a bit to get the mainspring wound enough by the rotor. These movements without hand-wound capacity are becoming rarer, and even Seiko’s or Citizen’s current entry-level movements can now be manually wound with the crown. Screw-down crowns, which are threaded and screwed tightly to the case for increased water resistance, simply need to be unscrewed before winding.

The crown is connected to the stem, which itself is connected to a winding pinion that engages with the mainspring barrel via a ratchet wheel. To simplify this a bit, the crown turns a series of gears that tighten the mainspring coil within a barrel, increasing the power reserve or amount of time the mainspring’s wound state will power the watch. If you pull the crown out to different positions, it will set the time, quickset date and other complications on the dial. As versatile as the crown is, some hand-wound watches use other methods to tighten the mainspring, although it’s rare.

The multiple positions of the crown are controlled by a mechanism named the keyless works, which gets its name from the fact that the movement doesn’t need a key to be wound or adjusted. This mechanism enabled the crown to have multiple functions and positions (winding, date setting, time setting, in most cases). A clutch wheel slides back and forth on the winding stem, which then interacts with specific gear trains in the watch’s movement.

The Key

The first pocket watches from the 16th century onward were wound by a separate key inserted into a hole at the back of the case or even within the dial instead of a crown (which is still seen in some mechanical clocks today). Convenient, integrated crowns began replacing easily lost keys in the early 19th century. English watchmaker John Arnold was an early pioneer in the development of a crown winding system in 1820, but it was Breguet who perfected crown winding by 1830. In the 1850s, Patek Philippe helped bring crown systems to the mainstream and finicky key-winding quickly fell out of favour.

Since the rise of wristwatches after World War I, virtually all timepieces are wound via the crown (pocket or wrist), but a small handful of specialised, independent watchmakers today use a key to honour watchmakers and innovations of the past, and/or also have an uninterrupted case aesthetic. Modern key-wound movements are hand-wound (no automatics), and a rare example is the Eccentricity by French Watchmaker Cyril Brivet-Naudot. It has a truly handmade movement without the use of CNC machines and is wound by a separate key from the back.

Another type of key is permanently attached to the watch with a handle that flips up for winding. An example of this is the inaugural Tourbillon Souscription from young independent watchmaker Remy Cools. Both winding and time setting were performed by two separate, flush keys on the back with flip-up handles, which is unique to say the least. Remy’s second variant, the Tourbillon Atelier, was redesigned with a conventional crown at 3 o’clock for winding and time setting. An identical system can be found on Astronomia watches by Jacob & Co.

The rotating caseback

Developed in 2001, the Ulysse Nardin Freak is an interesting example of a crown-less watch wound thanks to its caseback and adjusted thanks to a rotating bezel. The reason for this specific layout is not only a design choice, but lies in the architecture of the movement. On top is a flying carousel movement that rotates once per hour and whose main arm indicates the minutes. The mainspring was relocated underneath the movement. Coiled within a drum as large as the entire case, it would provide enough power to drive the movement for 7 days. This position explains why winding is done thanks to a rotating caseback. Some recent Freak models have opted for a crown at 3 o’clock, but most flagship versions are still using this architecture.

An identical system is used by Ressence, a crownless watch where the caseback is used to wind the movement and adjust the time. This choice is the result of the original display of the watch that doesn’t rely on hands but instead uses a module named ROCS, an orbital display with a rotating dial and revolving satellites.

Automatic Watches

Automatic movements use different types of weighted spinning rotors geared to the mainspring, which wind it as the wrist naturally moves. It’s hard to nail down exactly who invented this and when, but it can be traced back to the 18th century with watchmakers like Hubert Sarton, Abraham-Louis Perrelet, Joseph Tlustos and Joseph Gallmayr in the conversation. However, for our purposes, the first automatic wristwatch movement was invented by John Harwood in 1923-1924, which used a bumper system with a rotor swinging only 180 degrees, stopped by bumpers on either side. It wasn’t as efficient as today’s 360-degree rotors, but it revolutionised wristwatch movement design with a crownless winding system that debuted in 1926 through Swiss watchmaker Fortis.

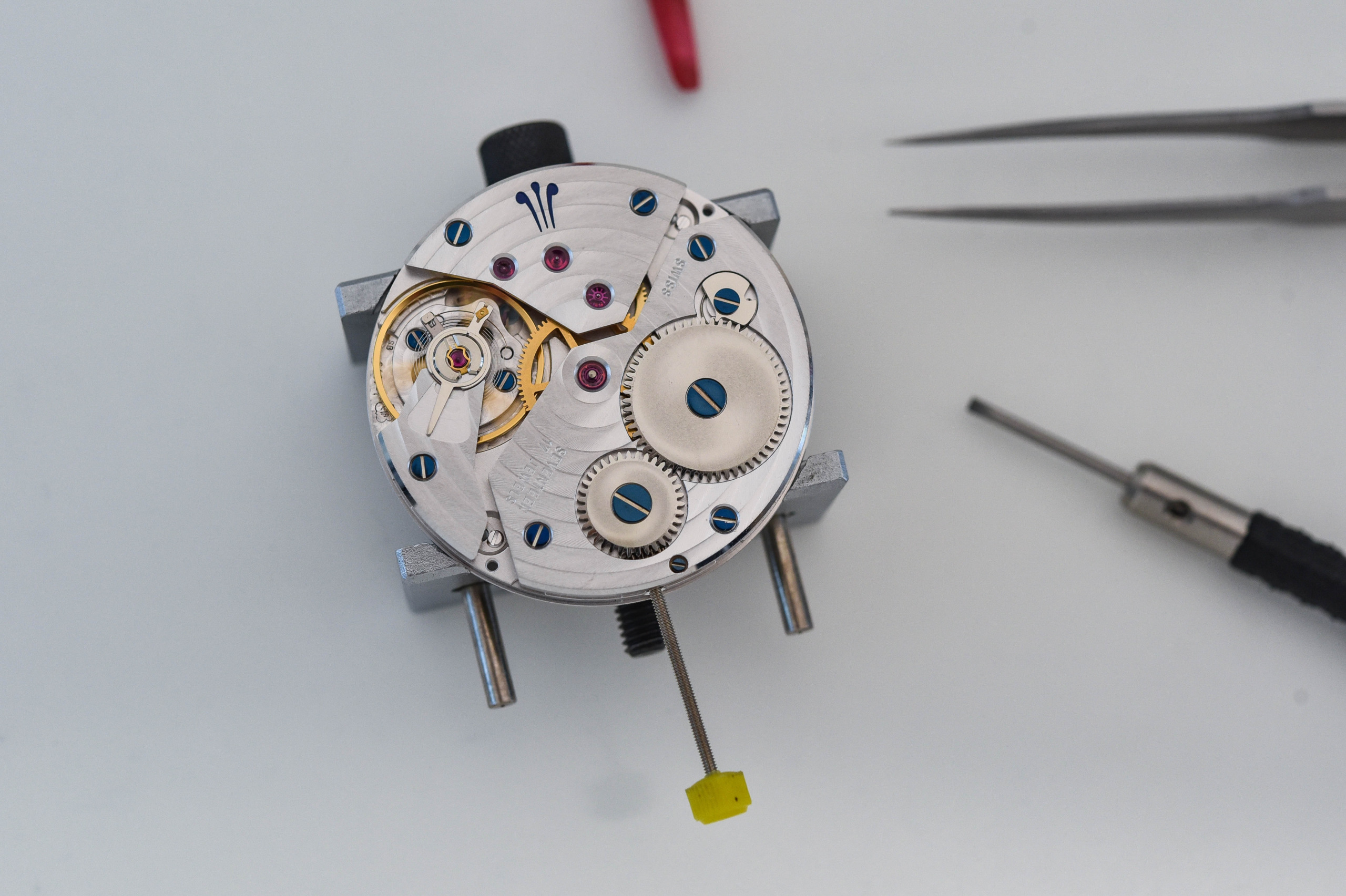

In 1931, Rolex perfected the automatic movement with a 360-degree winding rotor called Perpetual, which established a standard design. Combined with the water and dust-resistant Oyster case from 1926, the Rolex Oyster Perpetual has been a gold standard for automatic watchmaking for almost a century now. Conventional rotors generally cover half of the movement and swing over it, and many are decorated and/or open-worked to maintain an appealing aesthetic.

The central, 360-degree rotor is now the base for the vast majority of automatic watches, including industry-standard movements such as the ETA 2824, ETA 2892, Valjoux 7750 and variants by Sellita or La Joux-Perret, but also most in-house automatic movements from the entire spectrum of watchmakers, whether we’re talking about entry-level or high-end watches. The central rotor remains the most efficient and cost-effective type of automatic movement today, but there are two other principal types.

Micro-rotors

Micro-rotors are much smaller than conventional counterparts and integrated within the movement in a recessed aperture, usually off to one side. This allows a more unfettered view of the movement through exhibition casebacks, as conventional rotors block half of the view at any given time. By integrating the rotor this way, movements have thinner designs, since the rotor sits into the movement and not on top of it, and micro-rotor watches consequently have thinner cases, ideal for dress watches.

Micro-rotor movements are pricier than their conventional cousins as they’re more difficult to design and produce, and achieving a level of winding efficiency close to conventional rotors with such a small, off-centred mass is challenging. It’s debatable as to who invented it first, but both Universal Genève and Büren Watch Company developed the micro-rotor in the 1950s, as explained in this in-depth article.

Micro-rotor designs have come a long way, and winding efficiency is just about comparable to conventional automatics, and prices are dropping as well. Yema’s Navygraf Slim CMM.20 from 2024 is a good example with a French-made micro-rotor movement under EUR 2,000. French watchmaker Baltic has very popular and affordable micro-rotor watches like the MR Roulette collection, starting at less than EUR 600. They use very decent Chinese Hangzhou calibres, which help keep costs low. But it’s mostly in high-end watches with in-house movements that micro-rotors shine, with prime examples from Chopard L.U.C., Laurent Ferrier or Patek Philippe, to name a few. The use of a micro-rotor also helped Bulgari create the Octo Finissimo Automatic, one of the thinnest self-winding watches on the market.

Peripheral Rotors

Peripheral rotors blend the benefits of the central rotor and the micro-rotor, meaning efficiency on one side and compactness and an uncluttered view on the other. Through an exhibition caseback, the entirety of the movement is displayed as the curved winding rotor spins around the outermost perimeter. These are generally the toughest of the three automatic types to perfect, and watches are usually the most expensive. They went (somewhat) mainstream in 2009 after the Carl F. Bucherer Calibre A1000 debuted, but watchmakers have experimented with the concept since the 1950s. Swiss watchmaker Paul Gosteli patented the design in the mid-1950s, while Patek Philippe patented an improved design a decade later, but didn’t release a commercial watch until 1970. None of the early efforts proved particularly reliable or efficient until Carl F. Bucherer’s 2009 breakthrough, which was equivalent to Rolex’s Oyster Perpetual from a perfected design standpoint.

Unfortunately, peripheral rotor automatics remain expensive today as they’re just technically difficult to produce in numbers. For context, high-end brands like Vacheron Constantin, Audemars Piguet and Breguet produce the majority of peripheral rotor models with few exceptions, although they do exist. Swiss watchmaker Perrelet, for example, has the manufacture calibre P-411 peripheral rotor in the Lab Peripheral A1100/1 watch for USD 4,080, which is less than a comparable micro-rotor. Carl F. Bucherer’s latest Manero Peripheral starts at USD 7,900, which isn’t cheap, but still well priced for such a piece. The original 2009 Carl F. Bucherer A1000 introduced DLC-coated rollers and ceramic ball bearings to swing the rotor bidirectionally at the periphery, making it stable and reliable, and the ball bearings didn’t require oil.

Piaget is a notable pioneer with the thinnest peripheral rotor watch (and thinnest automatic watch in the world back in 2017) with the Altiplano Ultimate Automatic, powered by the calibre 910P in a 4.3mm case. The current world’s thinnest automatic watch, the Bulgari Octo Finissimo Tourbillon Automatic, also relies on a peripheral rotor to reduce its thickness to a mere 3.95mm, with a movement measuring only 1.95mm.

What Does it All Mean?

At the end of the day, a mechanical watch just needs a wound mainspring to run and the simplest of solutions to get there. Whether you do it by hand or let an oscillating weight do the job for you, the idea is to provide power to the mainspring. All of the winding examples in this article demonstrate innovation and technological advancements through centuries of watchmaking, from the earliest key-wound movements to the ultra-thin peripheral rotors. Enthusiasts have a very cool variety to choose from today, and there’s something for every budget.

1 response

Unless I overlooked it, no mention here of the JLC Futurematic ‘bumper automatic’ movements, like the Caliber 497, with a sliding crown on the case back to set time but not to wind the watch.