The Future Of Silicon Hairsprings, Now That The Patent Has Expired?

The patent restricting the technology to the CSEM consortium has now expired… and it might change the industry drastically.

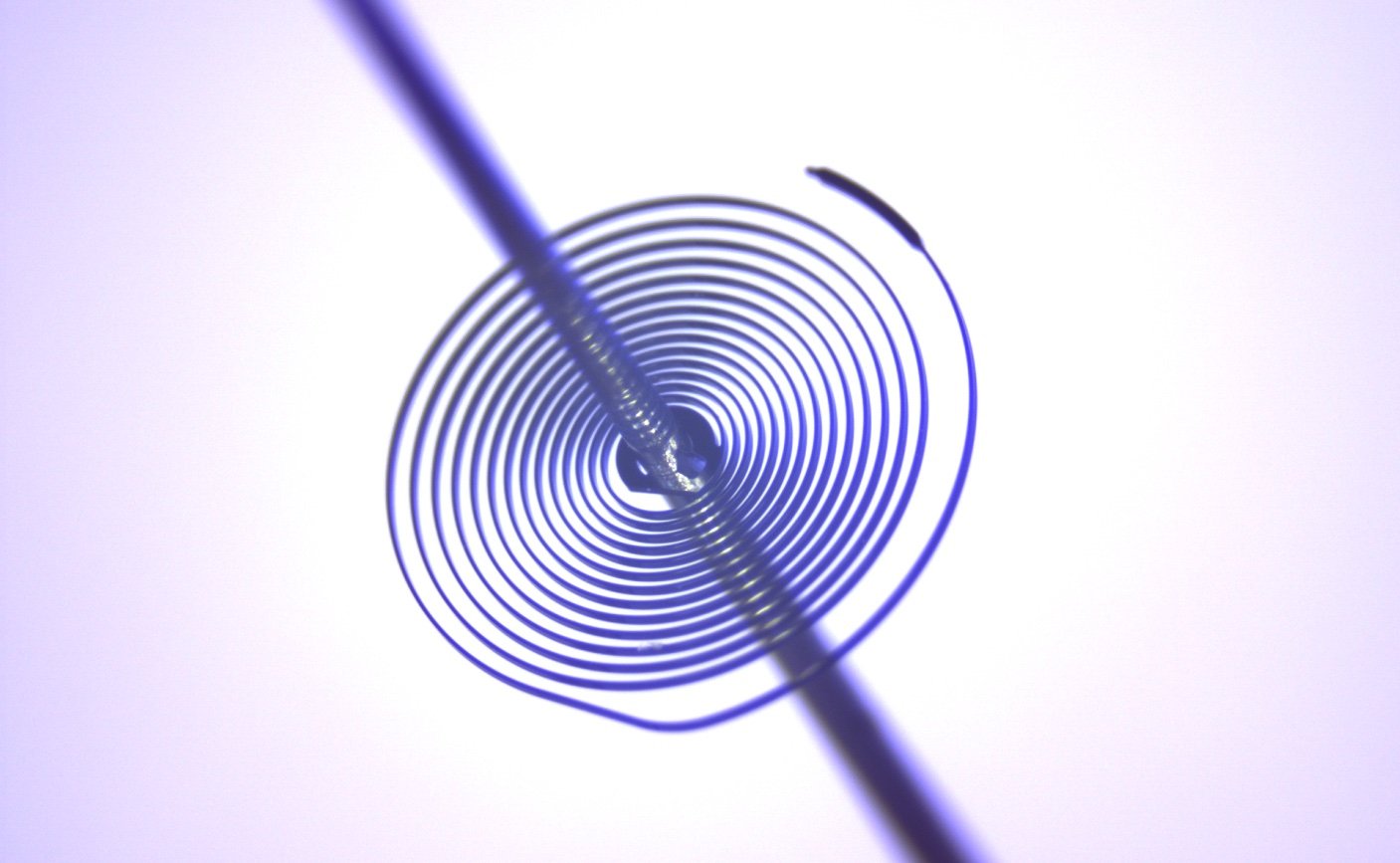

Barely one centimetre in diameter, the hairspring is the beating heart of a watch movement. It is a strategic component in several respects. Manufacturing hairsprings is a complex process mastered only by a few companies. Conventional hairsprings are made of iron-nickel alloys, such as Nivarox. For several years now, silicon has been revolutionizing traditional watchmaking. Borrowed from the semiconductor industry, silicon presents remarkable properties to manufacture hairsprings outperforming those made from conventional metal alloys. But until very recently, silicon hairsprings have been used by a limited number of companies, which patented the technology… Things might change as their patent has now expired. We could well enter the silicon age.

The benefits of the silicon hairspring

Not everyone is a fan of the modern silicon hairspring. Some wonder whether silicon has its place in a traditional mechanical watch. Others question the ability to restore movements with silicon components in the decades to come without having access to original spare parts – while re-manufacturing a traditional metal-based hairspring will always be possible. Still, this thermally stable, amagnetic, light, hard-wearing and durable material presents remarkable properties to craft hairsprings outperforming those made from conventional metal alloys.

Thermo-compensation – temperature changes are one of the key factors that may affect the performance of a mechanical movement and of its oscillator. In particular, a temperature variation results in a variation in the elastic modulus of the hairspring. Thermo-compensation can be performed with remarkable efficiency for silicon hairsprings via oxidization (which is precisely one of the central claims of the patent that has just expired – more information about this below).

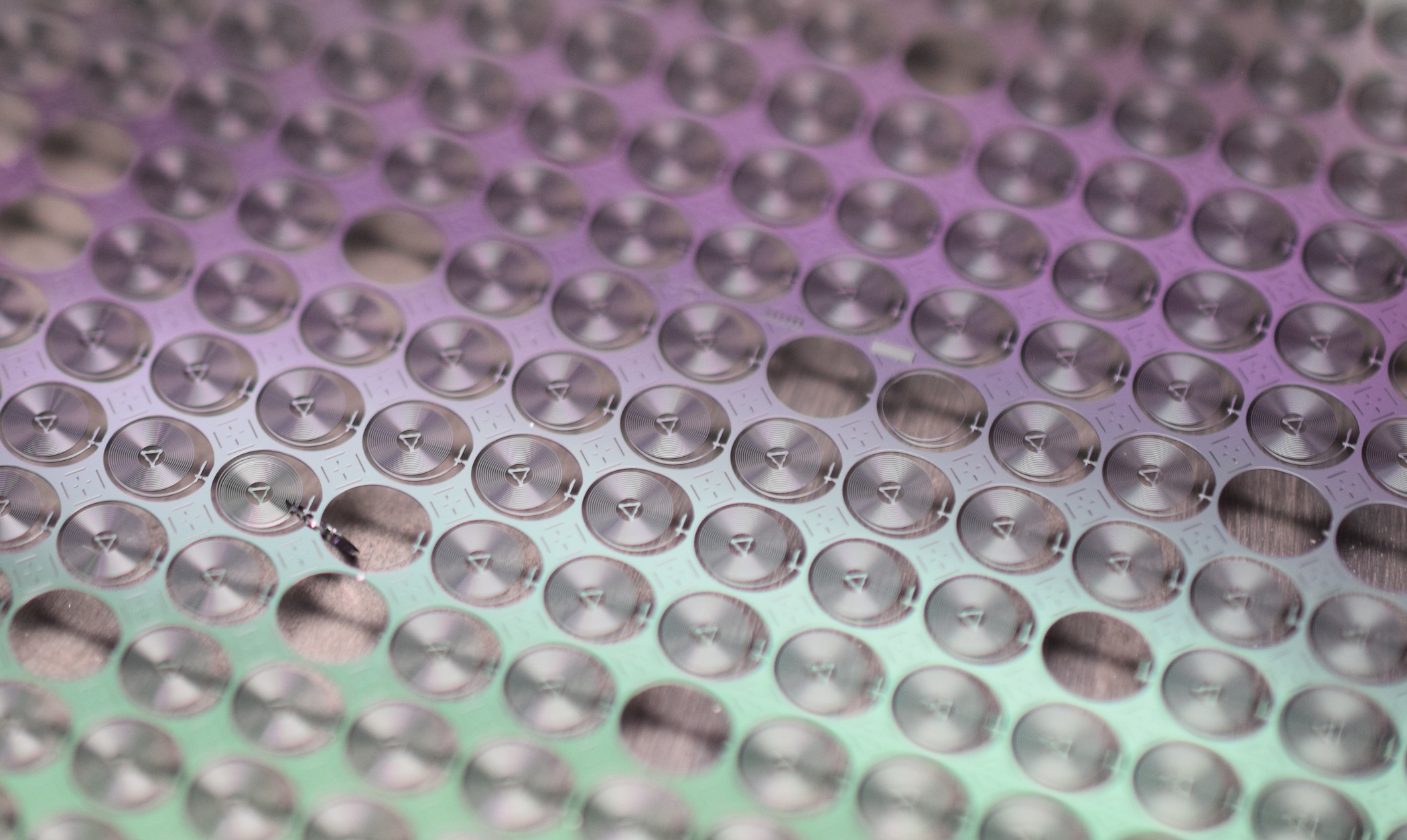

Chronometry – DRIE manufacturing (Deep Reactive Ion Etching) offers possibilities to create geometries that cannot be achieved for traditional hairsprings made of a uniform strip of metal. With silicon, different thicknesses can be implemented in different portions of the spring. This allows producing hairsprings with optimized isochronism, for instance, without the need to raise a terminal curve. If the design of a silicon hairspring is a complex endeavour, once an optimal geometry is determined, accurate parts can then be produced in large quantities with constant quality.

Resistance to magnetism – The internal parts of a watch can get magnetized, in particular, the hairspring and balance staff with a negative influence on the rate of the watch. There are only a few alternative solutions to overcome the main weakness of traditional ferromagnetic hairsprings. Silicon is one of these.

Pioneers of silicon and the CESM Consortium

The use of silicon in the watch industry was pioneered by Ulysse Nardin (with Ludwig Oechslin & Pierre Gygax on the technical side), in particular inside the Freak. If the 2001 Freak did not feature a silicon hairspring (only silicon escapement wheels back then), Oeschlin and Gygax are reported to have worked on silicon hairsprings at the time with the Neuchatel IMT. The main difficulty faced at the time was the sensitivity to temperature variations, with a large temperature-induced frequency drift.

The solution to this problem was devised by the CSEM – Centre Suisse d’Electronique et de Microtechnique – and in particular Claude Bourgeois, in the frame of a joint research project gathering Rolex, Patek Philippe and the Swatch Group. Thermo-compensation was achieved with a surface oxide, SiO2 being added in the form of layers covering the surfaces of a silicon hairspring.

In this frame, the technology allowing for the production of ultra-accurate and thermally compensated silicon hairsprings was protected by a patent (European patent EP1422436B1 filed on November 25, 2002). It was therefore restricted to the companies of the CSEM consortium, completed by Ulysse Nardin in the frame of a gentleman’s agreement.

Patek Philippe introduced its Spiromax® balance spring in 2006. At Swatch Group, Breguet pioneered the use of silicon balance springs in 2006 too, before the technology was used for other group brands. As for Rolex, the Syloxi hairspring was introduced in 2014 on calibre 2236, the first of a new generation of Rolex movements.

Entering the Silicon Age?

20 years after the original patent was filed and since it has now just expired (last Friday, to be precise), it will be interesting to see who will announce new silicon hairspring projects in the future, all the more as this will certainly open the door to more innovations. But the question is not as simple as it may sound. Mastering the industrial process of the production of silicon hairsprings and achieving the maximum yield over a wafer are not small endeavours, and cannot be achieved overnight. Besides, since 2002, additional patents have been filed in the field (for instance specific production processes, specific geometries, and specific ways to attach the spring) and new players literally need to navigate a legal minefield.

First, large groups or top-tier brands can be expected to be working on such projects (some might have been working on this for multiple years already). For the sake of using silicon, but also for a matter of independence with regards to the production of a highly strategic watch component.

In particular, if the TAG Heuer institute has been working on the development of carbon composite hairsprings, we would not be surprised to learn that the LVMH group brands would be conducting projects in the field of silicon hairsprings. In 2018, Richemont announced their Twinspir silicon hairspring technology with the Baume & Mercier Baumatic. If the production was stopped (due to the still existing patent of CSEM back then), silicon could very well be back soon with Richemont brands… only time will tell.

Besides these watchmaking powerhouses, smaller brands and independent suppliers can be expected to enter this market too.

As explained by Andi Felsl, founder of independent watchmaking brand Horage; “Silicon will kickstart innovation in all layers of the industry as we have seen it on escapement design following a prior patent expiry date in 2016. Silicon has the potential to afford more brands the opportunity to produce and deliver high-performance movements to the passionate watch enthusiasts that keep this industry alive.” Horage is now ready to equip their movements with silicon hairsprings after working on the development of their technology (with a partner in Germany to etch silicon) and the process of their assembly for years.

A joint venture created by Ulysse Nardin and Mimotec (now owned by Acrotec) to manufacture silicon components, Sigatec has been manufacturing hairspring for years. So far, the production was limited to Ulysse Nardin only, but Sigatec is investing to expand its production capacities and open such products to third-party brands.

Among the Swiss manufacturers of balance springs, Atokalpa (a company owned by the Sandoz Family, and then linked to Vaucher Manufacture and Parmigiani Fleurier) does conduct research on silicon. As far as Precision Engineering is concerned, their focus remains on their para-magnetic alloy PE5000.

And of course, new players are to be expected outside Switzerland. In particular, Damasko, a German-based manufacturer, proudly presents on their website their patented EPS silicon spiral… not to mention Asia and the Americas with for instance Master Dynamic or Firehouse Horology (the two photos you can see below).

While it is too soon to know exactly what has been done behind closed curtains by some brands, or what will be revealed in the coming months/years by large brands and groups, the expiration of the CSEM Consortium’s patent clearly opens the door to interesting development… however, keeping in mind that many other patents might have been filled in the meantime to still protect parts of the technology. Interesting times ahead…

Note – our focus in this article is limited to silicon hairsprings only, without exploring other materials or developments of new types of oscillators and escapements.

7 responses

Se abre la temporada de caza. Ojalá traiga a mediano plazo algunas buenas noticias para los segmentos medios y ¿porque no? bajos.

This begs the question of when tooling up with the newer technology, that when “older” movements with metal hairsprings go into be serviced, if the capability will include the ability to switch out the existing hairspring for a silicon hairspring. Has any consideration been given to this and can you comment?

Thanks, very interesting article. I own a Baume & Mercier Clifton with BM13 movement. On this particular reference, the silicon Twinspir hairspring was removed due to the patent topics mentioned in the news. I really wonder what will happen now, not just B&M, which I assume will be going back to BM12 with Twinspir, but in general on the market. I feel it’s going to be a major battle ground for the next years, and a major topic in the ’20s when we will look back in horological history. Let’s see 🙂

Not a fan of silicon hairspring, just my honest opinion, will require first if the watch has Silicon hairspring b4 buying

It appears the author of this article has no desire or knowledge to respond or provide input about the question posed in the comments section about the feasibility of retrofitting hairsprings made from older, non-silicon, materials. If you’re going to bring out an article such as this and it provokes questions regarding viability and circumstances for this technology, you ought to be prepared to try to shed some light on the subject, or at the very least, respond that you don’t know. And if you don’t know, don’t you think it may be a good subject to follow up on? It’s only a major development in the industry! Boy, did you drop the ball here.

@j. Quincy Magoo yes, on principle, you could switch from conventional to silicon and vice-versa.

One CENTIMETRE in diameter? I don’t think so……