EPHJ – Showcasing the future of the watch industry and more…

Behind the scenes of the watchmaking industry.

EPHJ is the leading professional show held annually in Geneva in the high-precision sector (in particular watchmaking but also jewellery and medical industries). The show is a multi-domain field for business interactions and the latest innovations that might impact the future of the industry. It attracts no fewer than 800 exhibitors from 20 different countries (June 12 – 15, 2018).

Most of the time, watch brands get all the credit for coming up with new products or concepts, while suppliers who work behind the scenes get none of the accolades. Without these behind-the-scenes players, many innovations would never find their way into the marketplace. To give credit where credit is due, here are some of the innovations that caught our attention when visiting the EPHJ 2018 fair.

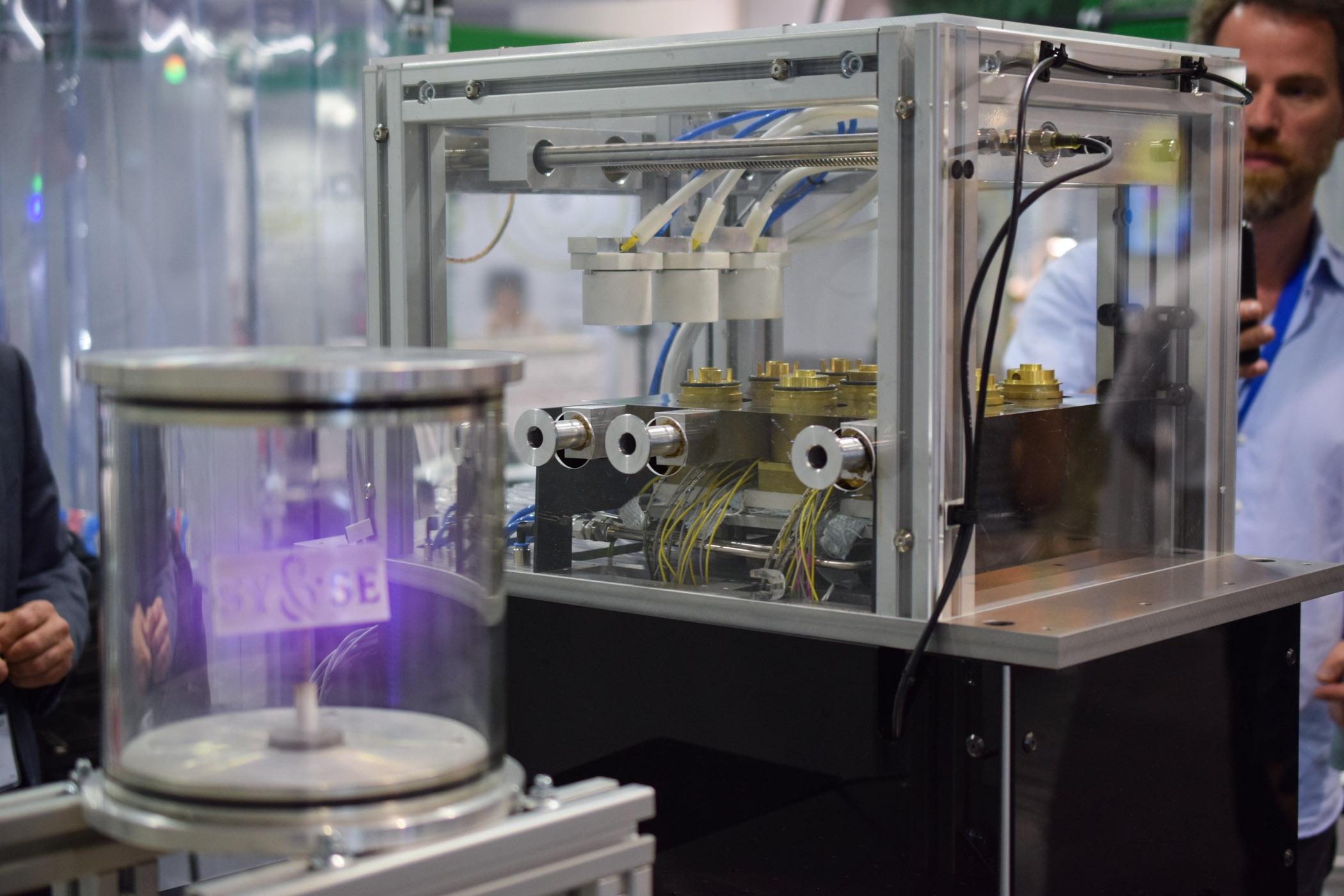

Sy&Se

Adhesives degrade over time and affect the quality of materials. The “Impulse Current Bonding” technology of this La Chaux-de-Fonds start-up is an enhanced form of anodic bonding, a process to seal glass to either silicon or metal without introducing an intermediate layer. Performed at a lower temperature using electromagnetic energy, it can be applied to a broader range of materials. With it, they create powerful bonds (on anything from glass and ceramics to metal) that do not degrade over time. Among the numerous potential applications, just think of sealing crystal to a case without glue or gaskets… More info at syandse.ch.

Vulkam

This French company industrialises various amorphous metals with outstanding properties that can be adapted to the applications. These are micro-moulded allowing the manufacture of various types of components. Wheels with outstanding tribological properties, superior springs or compliant mechanisms are some of the potential applications for watchmaking. More info at www.vulkam.com.

Acquandas

This German company has refined a technology to design and build flexible ultra-precise micro-components in 3D from anti-magnetic Nitinol (Nickel-Titanium alloy, a superelastic or shape-memory metal) or various other metals, for instance, to manufacture “smart anti-magnetic springs”. More info at www.acquandas.com.

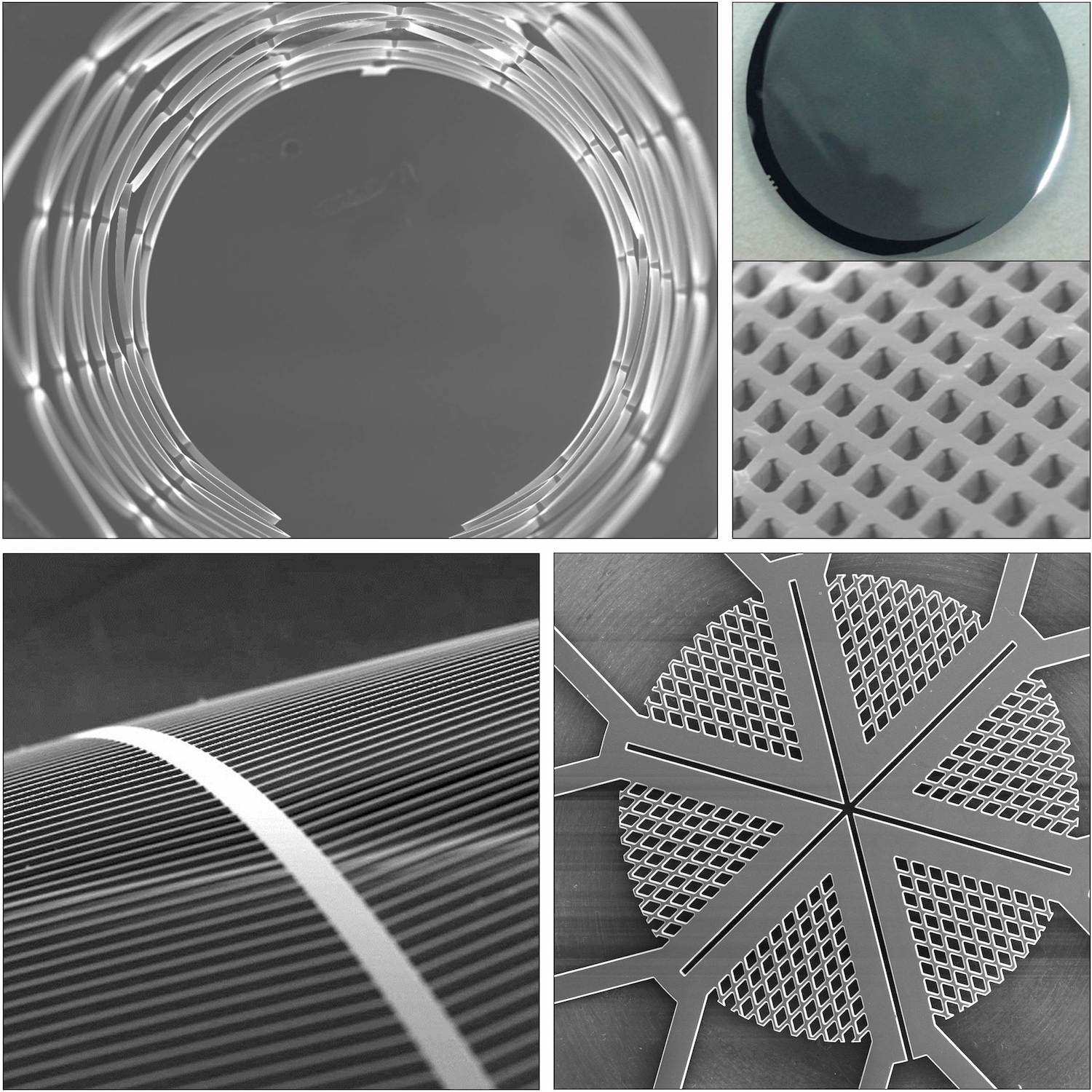

Optec

With their ‘MachCERAM’ technology, this Belgian company has developed an innovative processing of ceramics combining the speed of milling with the accuracy of the laser. Milling and laser milling are performed at the green (unfired) state. MachCERAM allows the processing of various ceramics with high ablation rates and extremely precise and creative geometries. This could be applied to manufacture complex–shaped ceramic parts such as cases, dials or movement parts. More information at www.optec.be.

CrystalTech

The Geneva-based company CrystalTech produces Crystalium, the commercial name of a crystallized metal made of ultra-pure ruthenium crystals offering a truly unique shine and superior resistance. More info at [email protected].

3 responses

Hi Xavier,

thanks for this insight. As you said, many watch companies could not innovate without having these providers behind them.

Hopefully we’ll see these materials and technology not only in prototype watches but in a broader “mass production” as well.

Regards,

slide68.

Hi Slide68, indeed. Some really interesting things there. Also with movement makers or craftsmen showcasing more traditional crafts. All the best, Xavier

Great to see this kind of reporting.

Wonderful sources to stimulate the imagination.