All About Omega’s Laboratoire de Précision, a new Chronometer Certification to compete with COSC, Open to all Brands

Reinforcing its position in the field of precision, this Omega-built label is independent, neutral and approved, but also answers to the growing needs of the brand.

Omega is one of the largest luxury watchmakers on the market, carrying multiple emblematic models (Seamaster and Speedmaster, to name a few). However, one vital element of the brand’s success lies in its almost unique take on precision. Omega has long been a pioneer in this field, often ranking first in chronometry contests and introducing solutions such as the co-axial escapement, the Master Chronometer certification or, recently, the Spirate system. Over-engineering and utmost precision are at the heart of the brand, and the latest step in the field of chronometry is named Laboratoire de Précision. A new, officially authorised chronometer testing laboratory meant to be integrated into the Master Chronometer workflow, the Laboratoire de Précision is open to any brand that would like to use its services.

I realise this announcement isn’t entirely new; Omega introduced it a couple of days before Watches & Wonders. However, I’ve waited to have more time to dig into this topic to deliver more than just a summary of the press release. So, this is what we know about Omega’s Laboratoire de Précision (or precision laboratory) and why it matters.

Chronometers, the COSC and other certifications

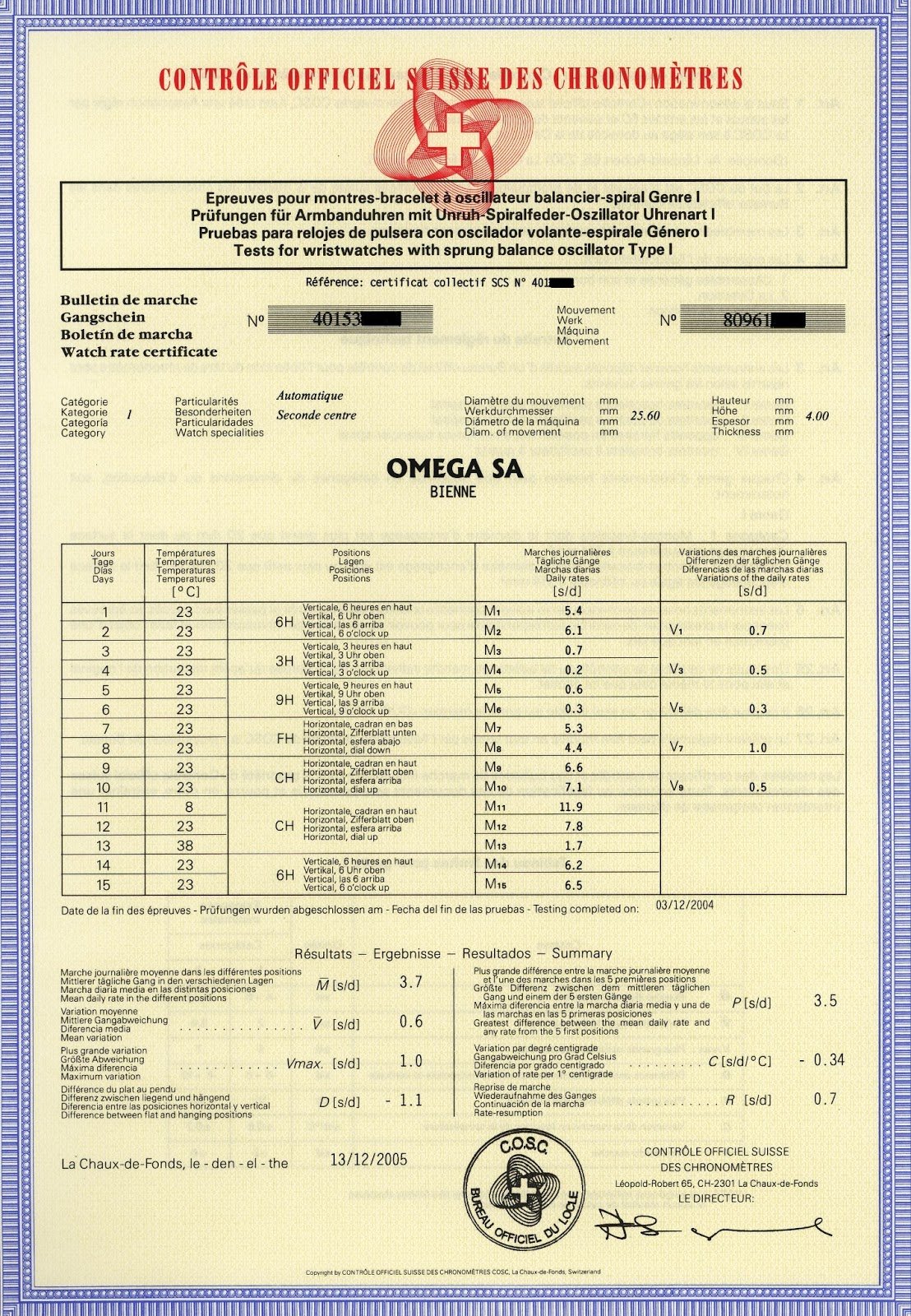

What is a chronometer? In short, it is a watch that has been officially tested for its precision (and no, it has nothing to do with a chronograph). Precision is a complex topic in watchmaking since time is a fixed norm, and a mechanical watch movement is, in essence, a man-made device that is subject to external factors and internal forces such as friction (all having an impact on the precision of the watch and its deviation from the standard time). In its modern definition, a chronometer is a watch that has been tested according to the ISO 3159 standard for “Timekeeping instruments – Wrist-chronometers with spring balance oscillator” and a certified chronometer goes one step further, being certified by a third party as a chronometer, for example by the COSC or another official authority.

Various organisations have the authority to test and certify mechanical movements, such as the Observatoire de Besançon in France, the Glashütte Observatory in Germany, the Japan Chronometer Inspection Institute or the recently created Geneva Observatory. For the past 50 years, the leading authority in this context has been the COSC or Contrôle Officiel Suisse des Chronomètres, created in 1973 (with origins dating back to 1878). The institute controls and certifies most of the watches produced in Europe.

The COSC runs a series of tests over the course of 15 days, operating independently with watch manufacturers sending movements to one of its facilities. COSC is not a free service, but whether a brand submits 100,000 instruments to the COSC or just one, the price per instrument is the same. “The checks performed by the COSC consist of static tests performed in the laboratory. Each individual movement/watch undergoes a battery of tests specific to each of the four types, for several consecutive days, in five positions and at three different temperatures.” To summarise, the COSC measures seven criteria, including the well-known average daily rate of -4/+6 seconds per day. This alone is not sufficient enough to make a watch a chronometer but it gives a solid indication of what to expect.

Recently, new standards reached the market, initiated by brands which felt limited by the ISO 3159 standard and thus the COSC certification. For instance, Rolex created its Superlative Chronometer standard, which implies a daily variation with a -2/+2 sec/day range. Yet, the brand still submits its watches to the COSC to have the right to use the “chronometer” name on the dial. Its main competitor and topic of the day, Omega, created the Master Chronometer certification in 2015, once again guided by the need for more precise watches but also by the addition of an important factor: anti-magnetism. Notably, the Master Chronometer certification was initiated by Omega and built together with METAS (Federal Institute of Metrology). It is also open to any brand that wants to use it… which is now the case for Tudor.

Omega and Precision

In addition to its most emblematic watches, Omega can be defined by its rather unique and superior take on precision. Historically, the brand was highly active in chronometry contests (a fashionable communication tool in the 1950s and 1960s), even submitting what’s known as the first tourbillon wristwatch ever made.

Using the idea of one of the world’s most revered watchmakers, George Daniels, Omega acquired the concept of the co-axial escapement and developed it at an industrial level. This original geometry of the escapement, replacing the classic Swiss lever, has been central in the brand’s continuous path to utmost precision. First commercialised in 1999 (it was developed in the mid-1970s but rejected by many brands), the co-axial escapement is now at the heart of almost all models in the collection.

In 2008, with the growing need for anti-magnetism, Omega introduced its first watch with a magnetic-resistant silicon hairspring (a patented technology and a joint research project gathering Rolex, Patek Philippe and Swatch Group). This was the first step in the creation of a specific precision standard, the Master Chronometer certification. Since the COSC primarily controls the precision of the movement, new technologies demand greater precision (in the case of the Master Chronometer Certification, -0/+5 sec/day), and the need to verify the magnetic resistance of watches required new facilities and testing procedures.

In January 2023, Omega pushed the limits of precision even further with the creation of the Spirate system. This device is designed to facilitate the fine-tuning of the rate of a movement. It combines a new silicon hairspring architecture and a new eccentric tuning system with a snail cam acting on a flexible blade. This system, with its unprecedented finesse, allows regulation as close as 0.1 seconds/day. This is achieved with a graduated tuner with a snail-shaped index on the cock. The result is a watch with a reported accuracy between +0 and +2 seconds/day. Here, too, the COSC testing procedure isn’t refined enough to guarantee the precision of such a movement.

Nevertheless, the Master Chronometer certification still required submitting watches to an official institute for chronometer testing – which Omega and Tudor obtained with the COSC. Well, not only now for the Biel-based manufacture.

Omega’s new Laboratoire de Précision

In yet another typical move from Swatch Group and Nick Hayek, who is at heart an industrial mentor with a strong desire for independence, Omega says creates a new chronometer testing authority. For over 50 years, the COSC has been Omega’s leading partner in granting certified chronometer titles to Omega watches. Considering the brand’s latest developments in precision and anti-magnetism, it was time for the watchmaking world to leap forward.

Omega once more wants to custom-build a testing laboratory to meet its ultra-demanding needs while respecting the classic codes of chronometer certification. Replacing the COSC in the Master Chronometer process, the new “Laboratoire de Précision will operate as the COSC, being officially authorised by SAS (the Swiss Accreditation Service) to carry out alternative and independent testing“.

An important aspect of Omega’s Laboratoire de Précision is that it is officially recognised as a laboratory according to ISO/IEC17025:2017 by the Swiss Accreditation Service – the only body in Switzerland authorised to deliver such approval. This guarantees that the Laboratoire de Précision will pursue reliable, independent, and impartial testing of watch movements, thus complying with the standard ISO 3159, commonly known as a chronometer.

Equally important, despite being initiated and operated by Omega, this Laboratoire de Précision is a neutral and independent entity, “offering chronometric testing opportunities for all brands and movement manufacturers.” It means that, in the near future, we could easily conceive that chronometer-certified watches from other Swatch Group-owned brands (think Longines, for instance) would be tested in one of the two dedicated sites of the chronometric testing. And maybe more, but it will depend on political, industrial and cost factors that only watch brands can solve together. After all, Tudor and, by default, the Rolex group moved to the Master Chronometer certification…

What makes the Laboratoire de Précision different from the COSC and similar entities? As explained above, the ISO 3159 standard fixes the bar at a relatively wide deviation of -4/+6 seconds per day, making it far less stringent than brands like Omega, Tudor or Rolex require for their watches. Also, the procedure defined by the COSC consists of precision measurements every 24 hours. The ISO 3159 standard also includes several positions and temperatures and various conditions required during the procedure for a watch to meet chronometer standards.

With Laboratoire de Précision, Omega aims for a continuous procedure throughout the 15 days of the tests. According to the brand: “Every beat of the calibre is measured and assessed, with a measurement accuracy ten times higher than the industry standard. The amount of data gathered during the tests, through industrial methods and big data analyses, will allow a brand or movement manufacturer to understand the chronometric performance of all its movements much deeper than ever before, while also helping to improve overall chronometric excellence.”

In addition, this Laboratoire de Précision testing method will meet the latest technologies developed by Omega, such as the Spirate system, which demands the latest technology in measuring systems. Omega will now “be able to analyse and improve its calibres for the future and refine the small margins that can determine (its) reputation“. Finally, this operation also allows the brand to better integrate chronometric testing into its own supply chain and, thus, into the whole Master Chronometer procedure.

The Laboratoire de Précision will have two sites in Switzerland, one in Bienne (Omega’s hometown) and one in Villeret. Together, they will create a dedicated space of more than 1,000 sqm for chronometric testing.

Reasons, thoughts and impact

Let’s first get to the topic of the impact, for you and us as watch enthusiasts, of this new chronometer standards. In all fairness, at the end of the day, the impact on the end consumer is not massive. Whether brands such as Omega, Tudor or Rolex use the COSC or another entity, most of the testing is done afterwards, internally and to even more stringent standards, and on encased watches, not only movements. It is always interesting for the watch enthusiast and potential client to know that his future watch has been tested to the best possible standards. Still, in the end, the COSC has long been more of an inevitable step in the Master Chronometer standard to comply with the authorities rather than a necessity. As said, the whole process defined by the Master Chronometer certification is far more demanding than just the classic ISO 3159 standard and the rules of the COSC.

From a watch nerd perspective and industry insider, I must admit that the whole strategy is impressive and only reinforces the idea that Omega is at the top of its game when it comes to precision. This move only strengthens the idea that Omega doesn’t develop technical solutions as communication tools but also takes great pride in demonstrating that these are actually beneficial to the product and can be certified.

The Laboratoire de Précision is yet another element in Omega’s long list of technical solutions and testing procedures developed to become the reference in precision – not only in mass-produced watches but for the whole watch industry. Omega is all about overengineering, to the point where some won’t care much anymore about it, but many will interpret it as the brand’s deep trust in the quality of its products.

The creation of the Laboratoire de Précision was also guided by the brand’s needs arising from the development of the Spirate system. I certainly can’t tell if discussions have been engaged with COSC to adapt the testing procedure to this new device, but the reality is that the Spirate system requires a stupendous amount of data to fine-tune the watch to the highly demanding accuracy standards.

What must be applauded in this context is the idea of being neutral, independent and fully approved by external authorities. Contrary to Rolex and its Superlative Chronometer certification or Patek Philippe and its in-house seal, both defined by the brands without external influence or control, Omega does things with a rare level of integrity and openness. The simple fact that the whole testing procedure is open to other brands says a lot about its intentions.

We can also look at the other side of the coin… It is known that Swatch Group and its president, Nick Hayek, have long been guided by the wish to become as independent as possible. The COSC was almost in a position of monopolising chronometer certification, something that Mr. Hayek might not have appreciated, specifically if the latter wasn’t in a position to change its testing procedures according to Omega’s needs. Then, there must be other reasons that can’t be confirmed (and won’t be confirmed), such as costs and possibly political talks that will remain behind closed doors. And it may be for the best.

In the end, the Laboratoire de Précision launches as a strong alternative to a household name in the industry and shows that what seemed established can be questioned and rivalled. It is yet another stone in Omega’s process of building the most accurate mechanical watches possible. The question is if and how quickly other brands will jump on this Lab’s bandwagon.

For more details, please visit www.omegawatches.com.

1 response

Fascinating stuff, Omega just needs to build a watch I’d like to own and I’ll buy one.