Seasoned Watchmaker Dann Phimphrachanh And His Stunning Seconde Vive

A splendid debut by an AHCI Candidate, who's had one of the most surprising journeys into independent watchmaking.

In today’s indie watchmaking scene, you might think you’ve seen it all, but in reality, there is still a lot to be discovered, even for us. After scouring the globe, for the most part virtually, we’ve uncovered some of the most intriguing, beautifully constructed and finished watches. We see amazing work being done in South Korea, Japan, Canada, the Netherlands, Finland, Denmark and many other places. Next in line is another stunner, this time made in Switzerland by a seasoned watchmaker with Portuguese and Laotian roots. This is Dann Phimphrachanh and his amazing debut piece, the Seconde Vive!

Small-scale traditional watchmaking has undergone a resurgence in the last couple of years. We see tons of new and often rather young watchmakers making a smashing debut, seemingly coming out of the blue. But in reality, these youngsters have often been training and working for years, perfecting their skills and learning the craft to the point they are capable enough to step out onto the big stage. And a stage we always try to offer, as this sort of watchmaking is dear to us. So when we hear of a talent on the rise applying to be a candidate for the Académie Horlogère des Créateurs Independants (AHCI), we tend to get a little bit excited!

To Dann, the AHCI is a bastion of craftsmanship in the face of an industry focused exclusively on profit, even if it means passing off certain industrial products as “independent” or “in-house”. Such is the story of Dann Phimphrachanh (pronounced “Fin-Fra-Chan”), a man with a very interesting journey into watchmaking, working for Parmigiani Fleurier, Greubel Forsey, Daniel Roth and Jaeger-LeCoultre. He is now seeking the spotlight with his very own watch, the Seconde Vive.

Dann, you’re born in France, with Portuguese and Laotian roots, producing watches in Switzerland. That sounds like quite the journey!

Yes, it was a long journey. Let’s just say that the pleasure of practising watchmaking in its purest form was strong enough to pass through certain periods, often decisive and uncertain. To cut a long story short, I was born in France and moved to Portugal at the age of 8, finally settling in Switzerland at the age of 24 in search of mastery in the art of watchmaking.

How did you get interested in watchmaking? What was your earliest memory?

It was a chance that led me to choose watchmaking at a technical college. I had gone there to enrol in blacksmithing or electronics, but when I visited the watchmaking department, I remember seeing a certain beauty in the crafted pieces and movements that I hadn’t seen in the other trades. This visit was my first contact with watchmaking; I was 14 years old.

Where did you study the craft, and what pushed you to venture out on your own?

It was at the Watchmaking School in Lisbon, in the city of Belem. Like many schools abroad, Swiss companies are very involved in teaching, which means that all our teachers travel extensively to Switzerland or have had professional experience that has given them an inside knowledge of Swiss watchmaking. Independence and creativity are therefore integral to the school’s ethos, along with immense admiration for those who are or have been important figures in the watchmaking tradition. There was nothing better to spark the curiosity of the young student that I was, eager to learn.

Your first watch is the incredible Seconde Vive. What can you tell us about its inspiration?

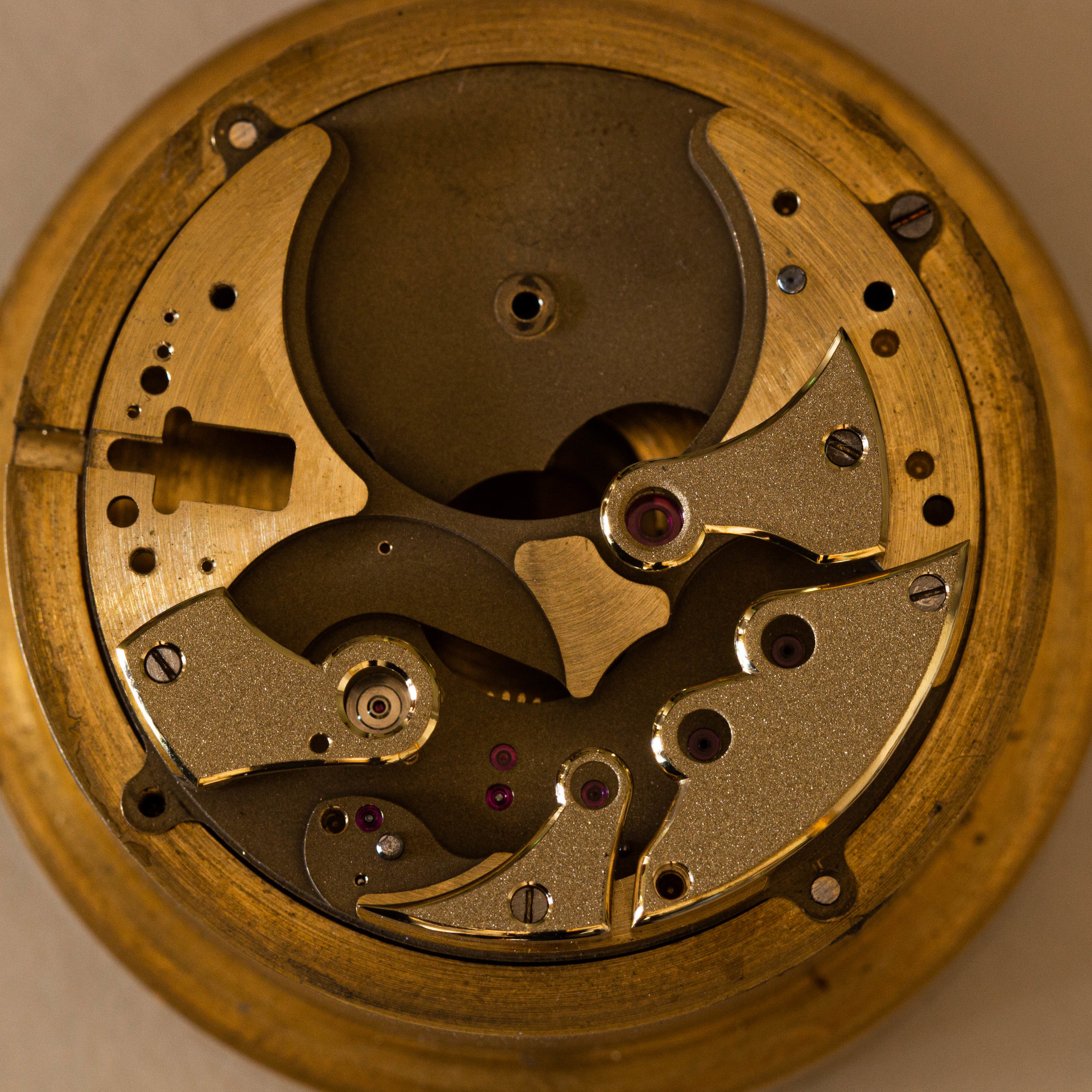

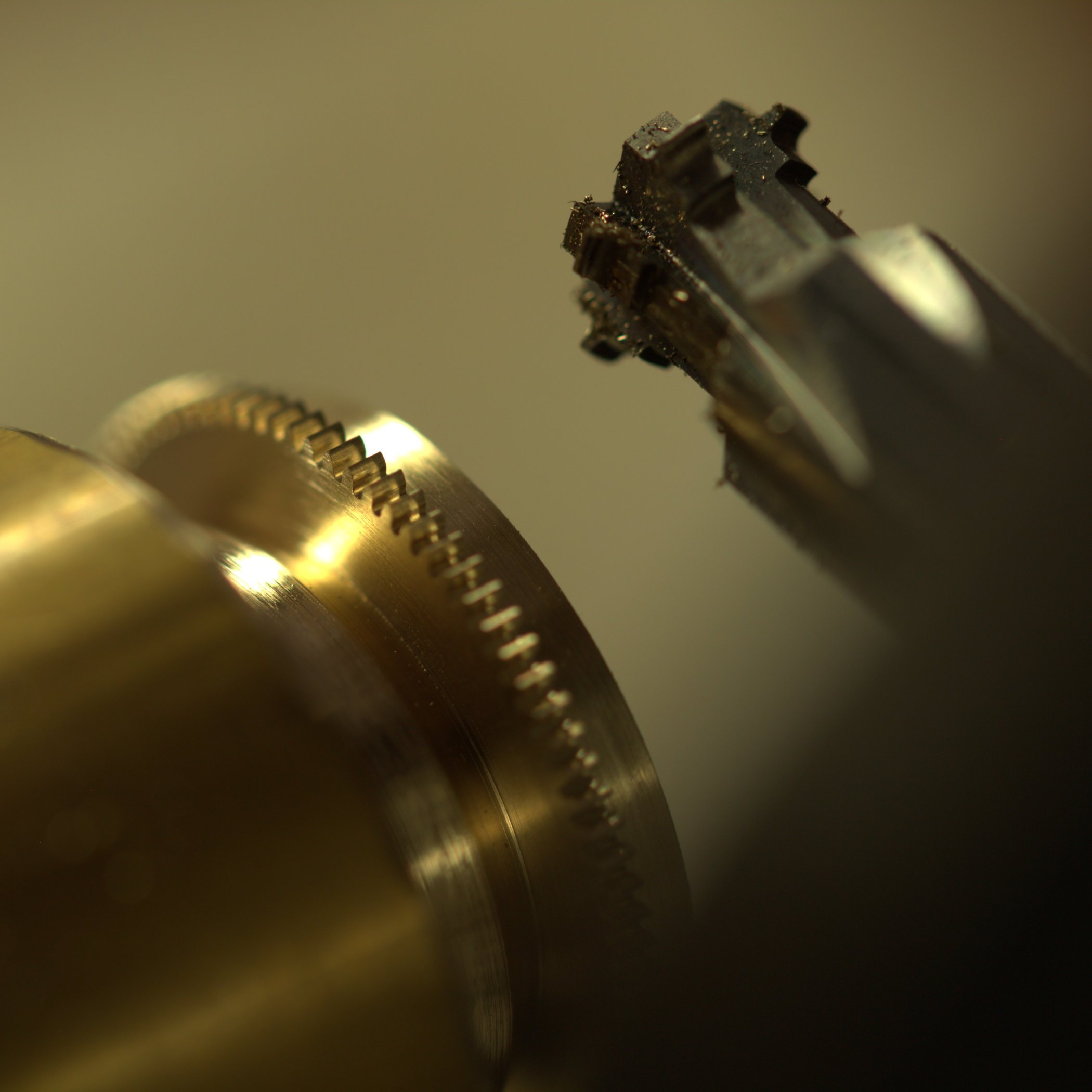

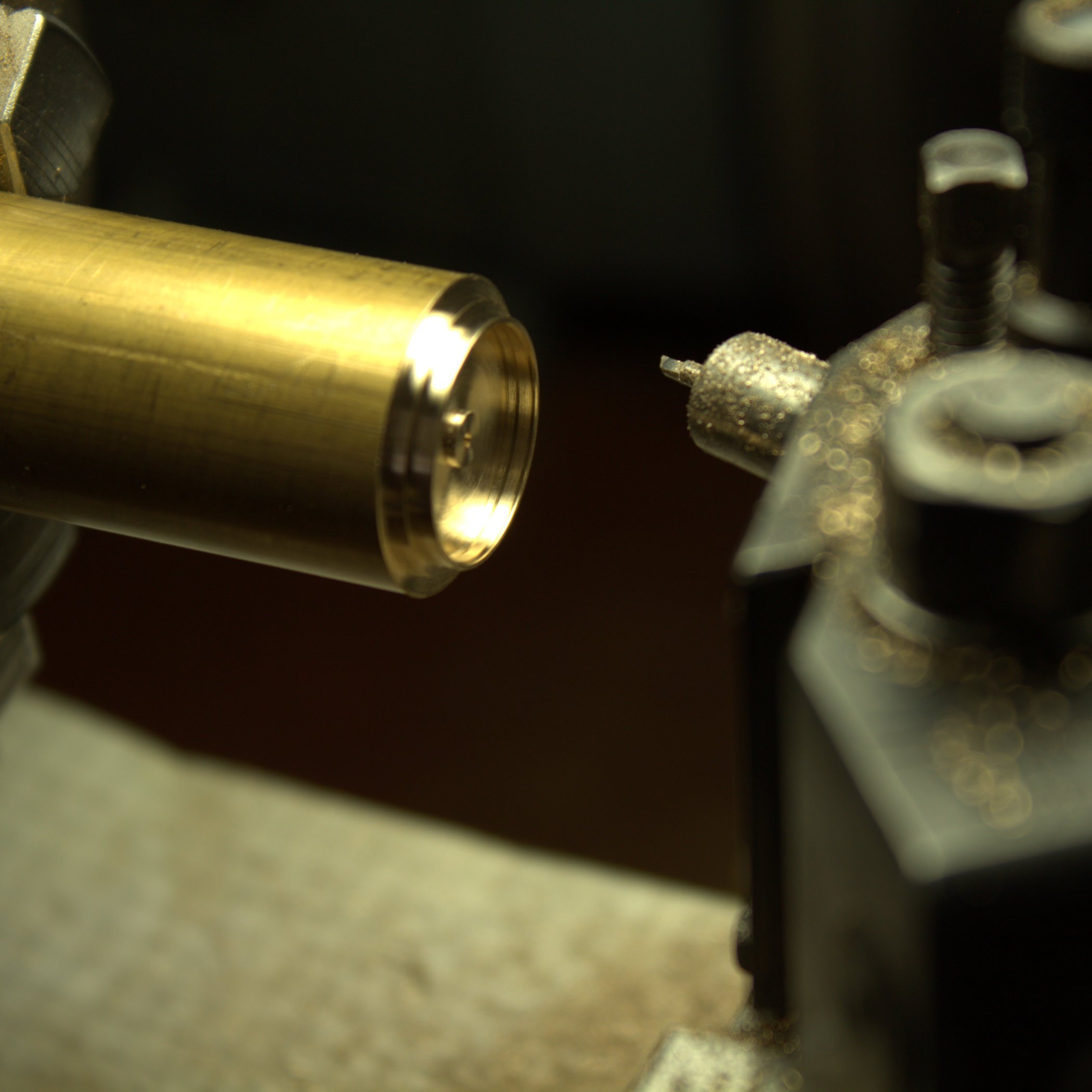

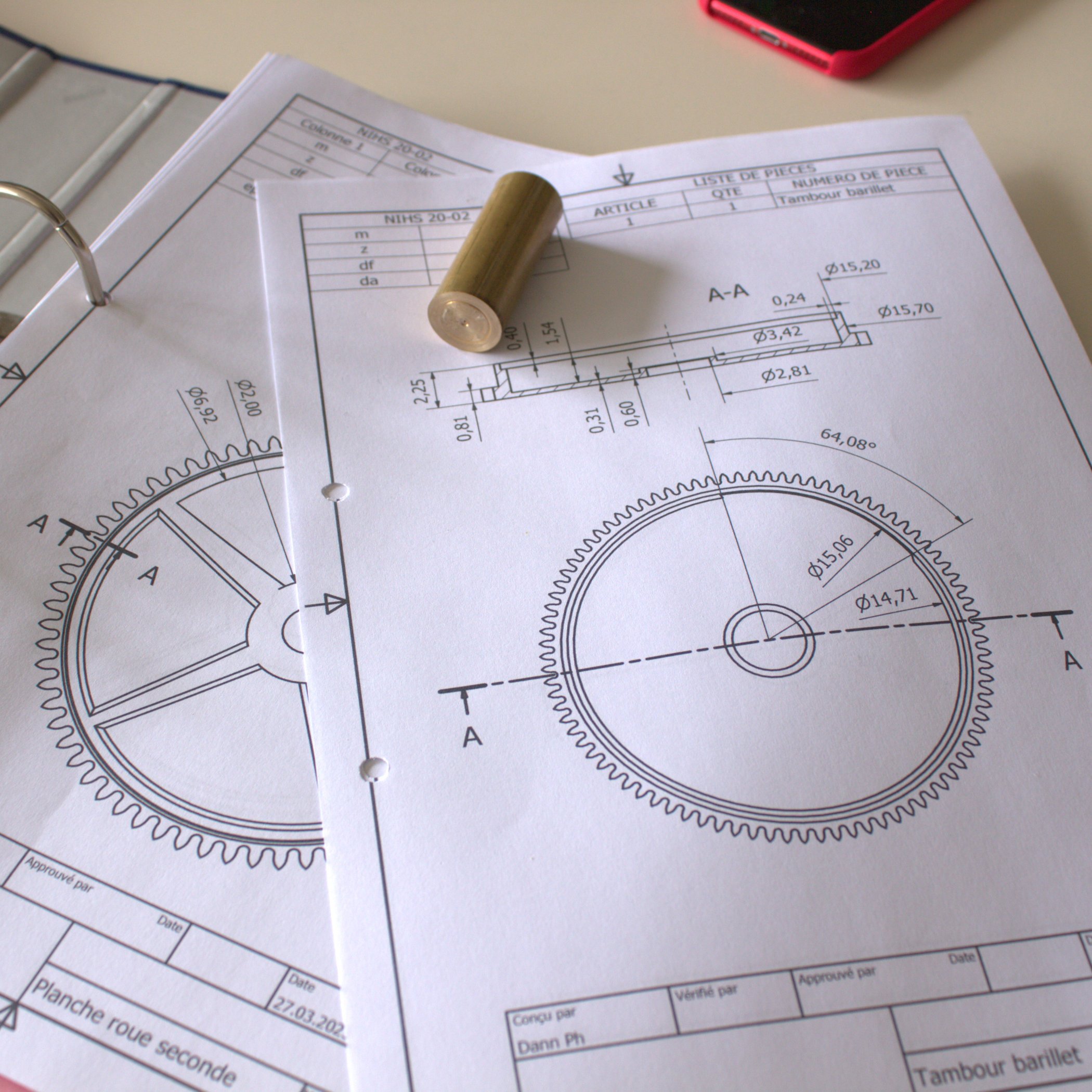

Coming from a school in Lisbon, I always felt a lack of legitimacy. Even though I had the opportunity to work alongside extraordinary colleagues and on exceptional products for the most renowned brands, I wanted to make a watch that was technically challenging, yet also simple and traditional. To achieve this, I wanted the watch to be mechanical, with a movement that could be perceived by the human eye. I also wanted the parts to be made exclusively with manual machines that were common before CNC technology, and without any surface treatment.

What were your biggest challenges to overcome?

The biggest challenge was maintaining a parallel activity to pay the bills, while at the same time managing a creative project that demanded a great deal of intellectual energy. In my case, I wanted to isolate myself in order to create without outside influences, which ended up being difficult to manage at times. It took a few years before I was able to transform solitude and everything that comes with it into strength.

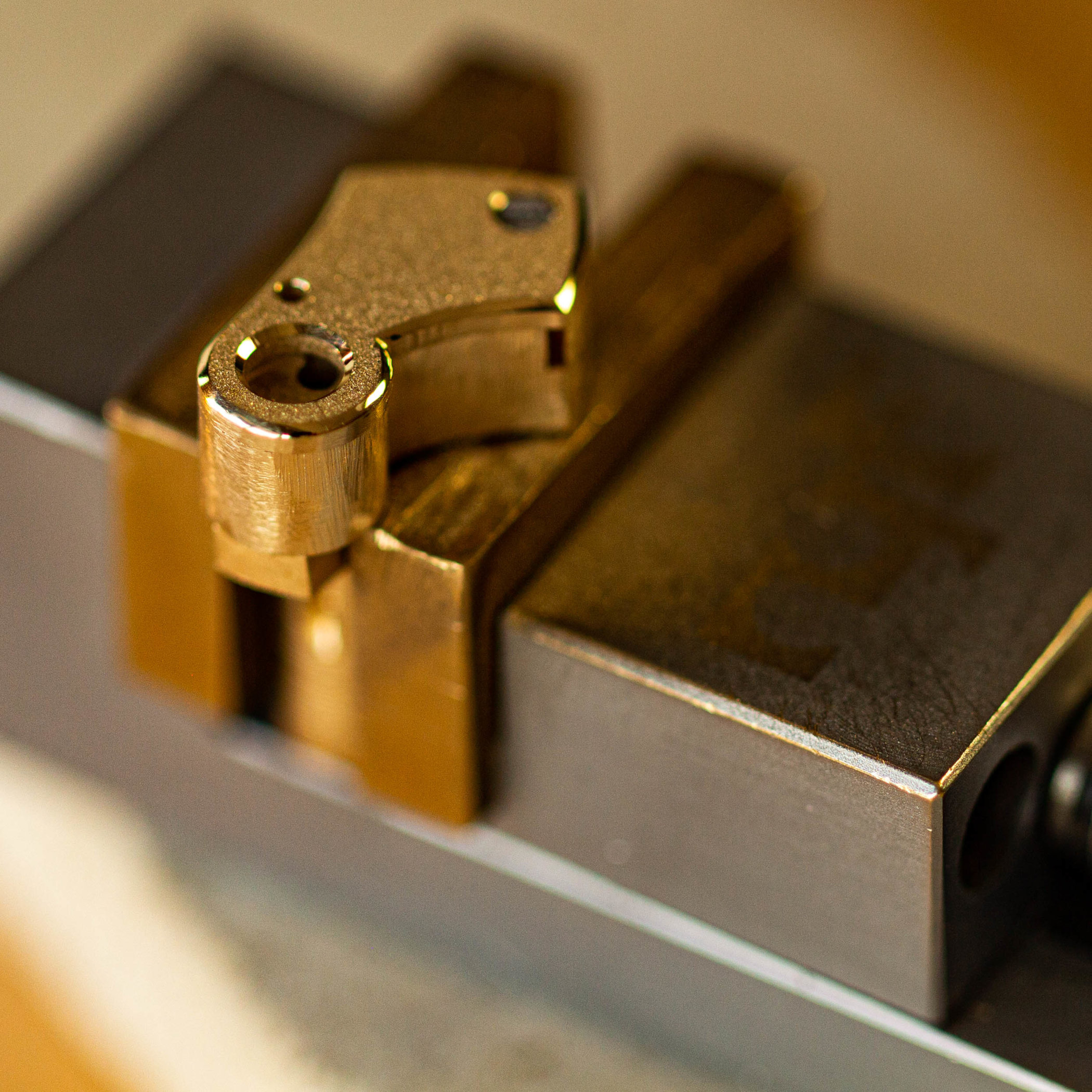

The Seconde Vive uses a rather special seconds mechanism, with a Reuleaux cam. What can you tell us about this?

Before using this mechanism, I tried two completely different mechanisms, which proved to be too energy-intensive. The Reuleaux triangle was an obvious choice that I tried to avoid, but this system is undoubtedly the most stable I have been able to experiment with. After designing two other mechanisms with several modifications, I ended up working on the Reuleaux triangle with three major modifications to achieve the desired result. Space, aesthetic potential and energy for the system were decisive factors in this choice.

A lot of your work is done in-house and by hand. Can you elaborate on this?

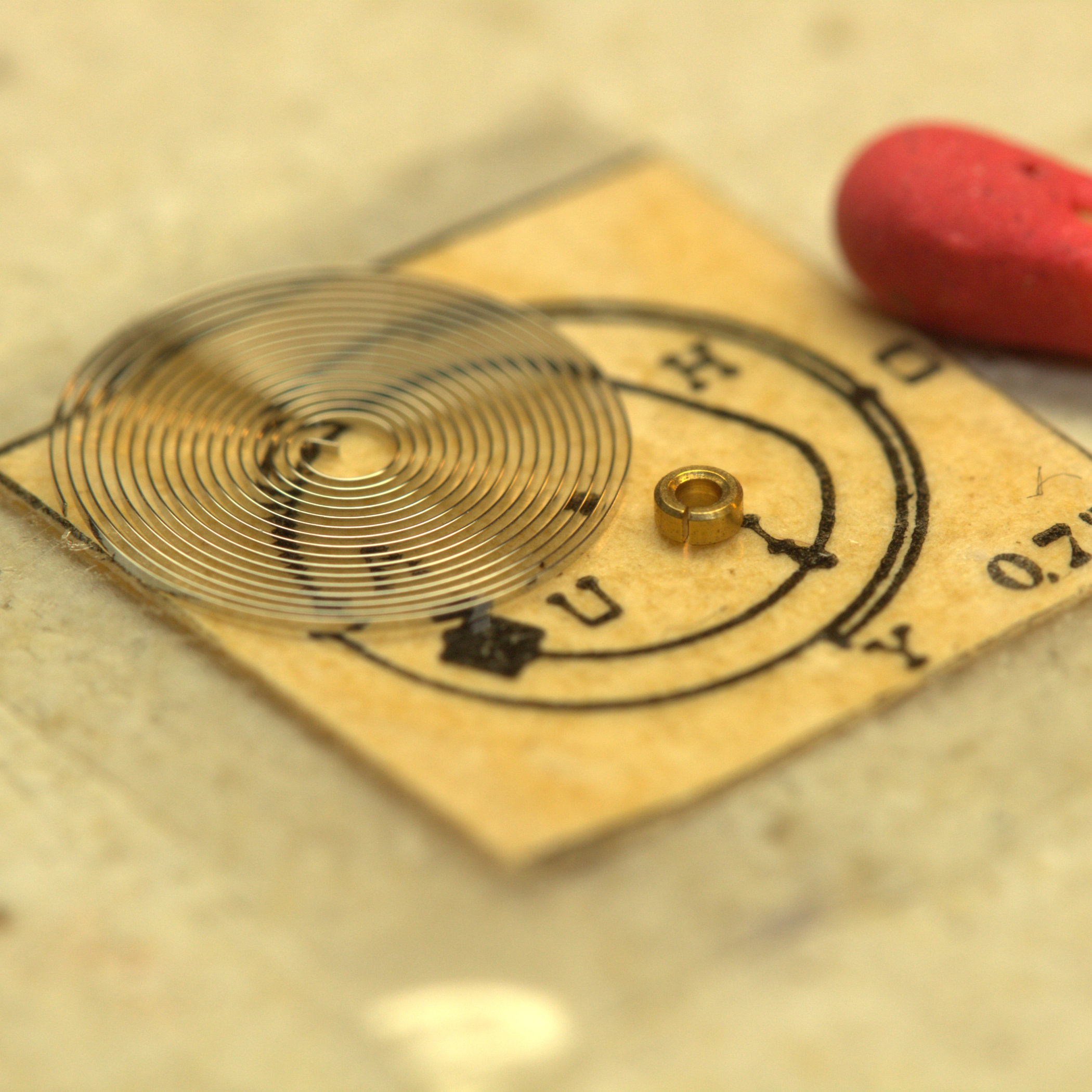

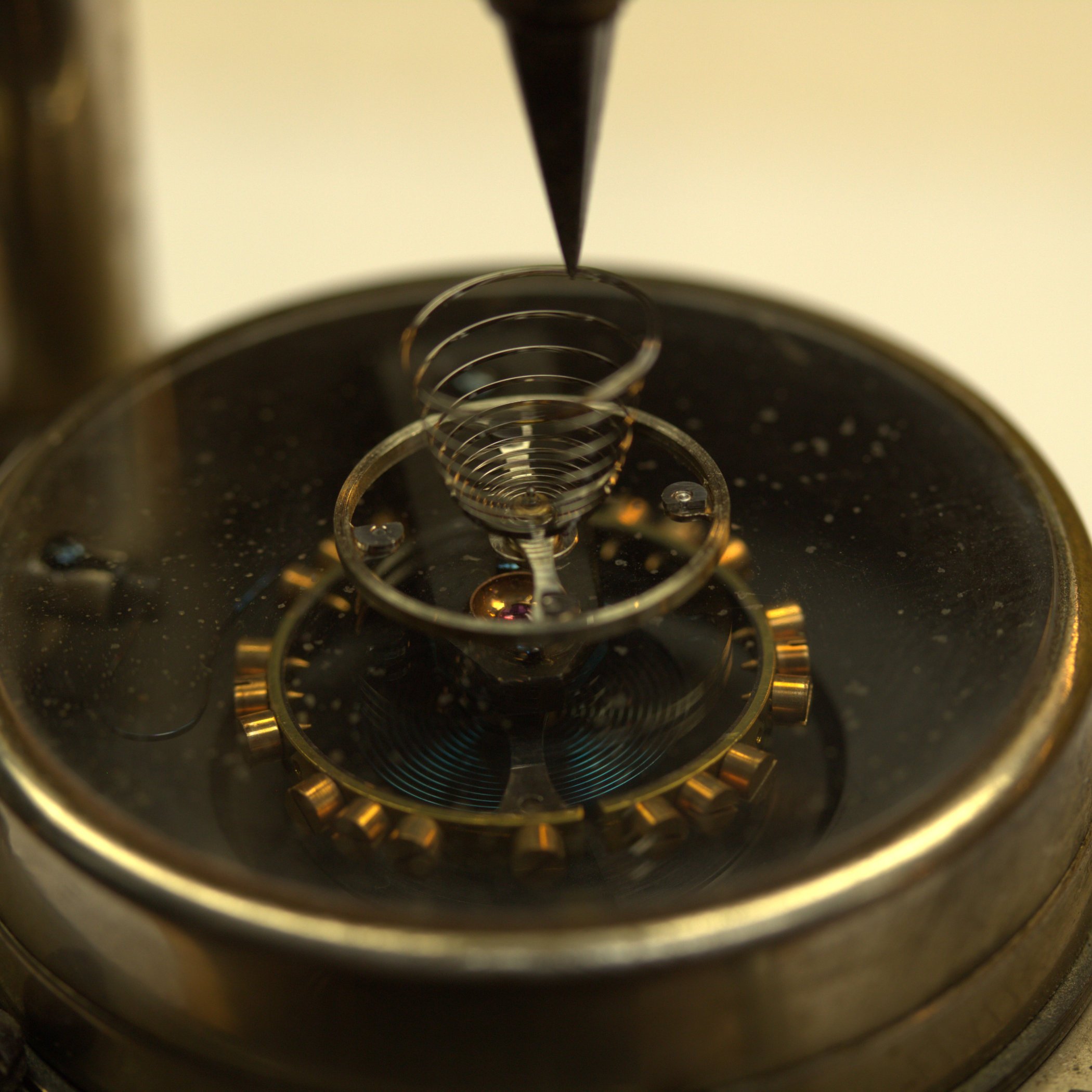

As a self-employed craftsman working alone, it is impossible for me to manufacture my own balance springs or barrel springs, or even rubies. For this reason, and to ensure that my watches can be repaired effectively by any good watchmaker in the future, I have used an existing hairspring and barrel spring, which are easy to find.

I have designed, developed and manufactured everything between the two springs. The plate, all the bridges, wheels, pinions, balance wheel and escape wheel are imagined and made by me using traditional methods. The same goes for the case, buckle, dial and hands. For practical reasons and in line with my current manufacturing capabilities, I also use three existing parts for setting the time: the stem and the two pinions that work on it.

Is it available to people, and how many are you planning on making?

It’s a complex issue, but to put it simply, I currently have a waiting list of over 10 years if I count all the official requests from ‘certified’ collectors. Given the way this watch is made, I can’t produce more than six watches per year. For the moment, the first three years have been reserved. I am keeping a waiting list and will let those for whom I would be delighted to make a watch know in three years’ time. This sorting stage is not my favourite part of the process; let’s just say I would gladly do without it.

Any thoughts on what’s next for you? Do you have some ideas for future watches already?

Another complex issue that regularly weighs on my mind. I am eager to pick up my pencil and make some sketches. Let’s just say that for now, all my energy is focused on developing my workshop to maintain a truly handmade approach and steering clear of the temptation to respond positively to too many clients, which would potentially lead me to take shortcuts. We have an honourable profession, and it would be detrimental not to act in accordance with the image that craftsmanship represents. Let us take advantage of the opportunity that the market gives us to give meaning to the term ‘handmade’, even if it means a more human production, less quantitative.

You’re also an AHCI candidate. What does this mean for you, and what are the benefits?

For me, being a candidate and participating in the Masters of Horology (An AHCI-hosted event in Geneva during Watches & Wonders) alongside renowned watchmakers who fly the flag for craftsmanship in its purest form is a dream come true. To be honest, I never thought I would be capable of doing this one day, especially since, for me, the importance has always been based on the technical knowledge required to present a watch. For this reason, being alongside all the watchmakers of the AHCI is truly an honour and a pleasure. When it comes to the conditions necessary for producing a watch, it is also an advantage to have been ‘knighted’ as a candidate for the AHCI. I am fortunate to have Raul Pagès and Bernard Lederer as my mentors… I couldn’t have asked for better.

I must also say that the AHCI is a wonderful ecosystem for independence. Even if some watchmakers are not members of the AHCI for reasons of their own, the spirit is global and brings together the most passionate individuals who are always ready to exchange and share ideas. For example, Florian and Gael from Petermann Bedat legitimised me by sending me a collector who became a friend, even though they didn’t know me before coming to visit me out of curiosity after I approached them with a simple phone call.

Luca Soprana from Derek Pratt, whom I have known for a while but had lost touch with, recommended me to many collectors after seeing my watch. The same thing happened with Raul Pagès and others. After years of solitude and creation, feeling so welcome among my peers is truly gratifying. The AHCI is clearly the core of the independent spirit, and this mindset extends far beyond.

What do you hope to achieve on your watchmaking journey?

Today, I would like to achieve a trilogy that is exclusively handcrafted, but it is still too early to make plans for that. It could take decades, one step at a time.

How can people get in touch with you to learn more about your work or reserve one of your watches?

I will be at the next MOH next year with the AHCI. In the meantime, I have an Instagram account and an email address ([email protected]) where I can be reached. Unfortunately, I am not always able to respond quickly, but even if it takes weeks or months, everything is saved, and I take the time to respond slowly, putting the watchmaking work priority.

For more information, please visit Dann’s Instagram account.

1 response

An exceptional product made by an exceptional watchmaker! Great article as it tells the story of the man C.V. as well as the first watch he has made.