Independent Watchmaker Reuben Schoots Offers An Insight To His Series Two Watch

It's far from easy to create a watch, especially the old-school way.

Although we’ve never handled one of his watches, Australian independent watchmaker Reuben Schoots left a lasting impression on us with his Series One watch. We talked to the man himself about his very first creation, learning the incredible background of how he got into watches and came to making the Series One. When we published that first interview, he already hinted at what would come next, the fittingly named Series Two, obviously. And recently, Reuben presented the final design to the public and of course, we wanted to find out more. But instead of offering you a glimpse of a watch you can’t get (as it’s pre-sold unfortunately), we decided to give you an inside view into what it takes to create such a watch with input from the man himself.

The Series Two is Reuben’s second (sort of) serially produced watch and is a continuation of the Series One. Reuben put all the lessons learned to come to the production of the Series One into this follow-up watch and pushed himself even further. Although it might not look like it from the get-go, there’s even more artisanal work involved with this one. He’s currently moving from the prototyping to the production phase, which is a monumental step in such a project.

As a result, some of the parts shown in the pictures are not yet fully finished or might be subsequent to small tweaks to make it as perfect as can be. And although the Series Two looks a lot like the Series One, it is in fact designed from the ground up. All the more reason to have a talk with the man who created it to learn more about the Series Two and the challenges it provided compared to his debut Series One.

Robin Nooij, MONOCHROME: What are the main differences between the Series One and Series Two in terms of technical construction?

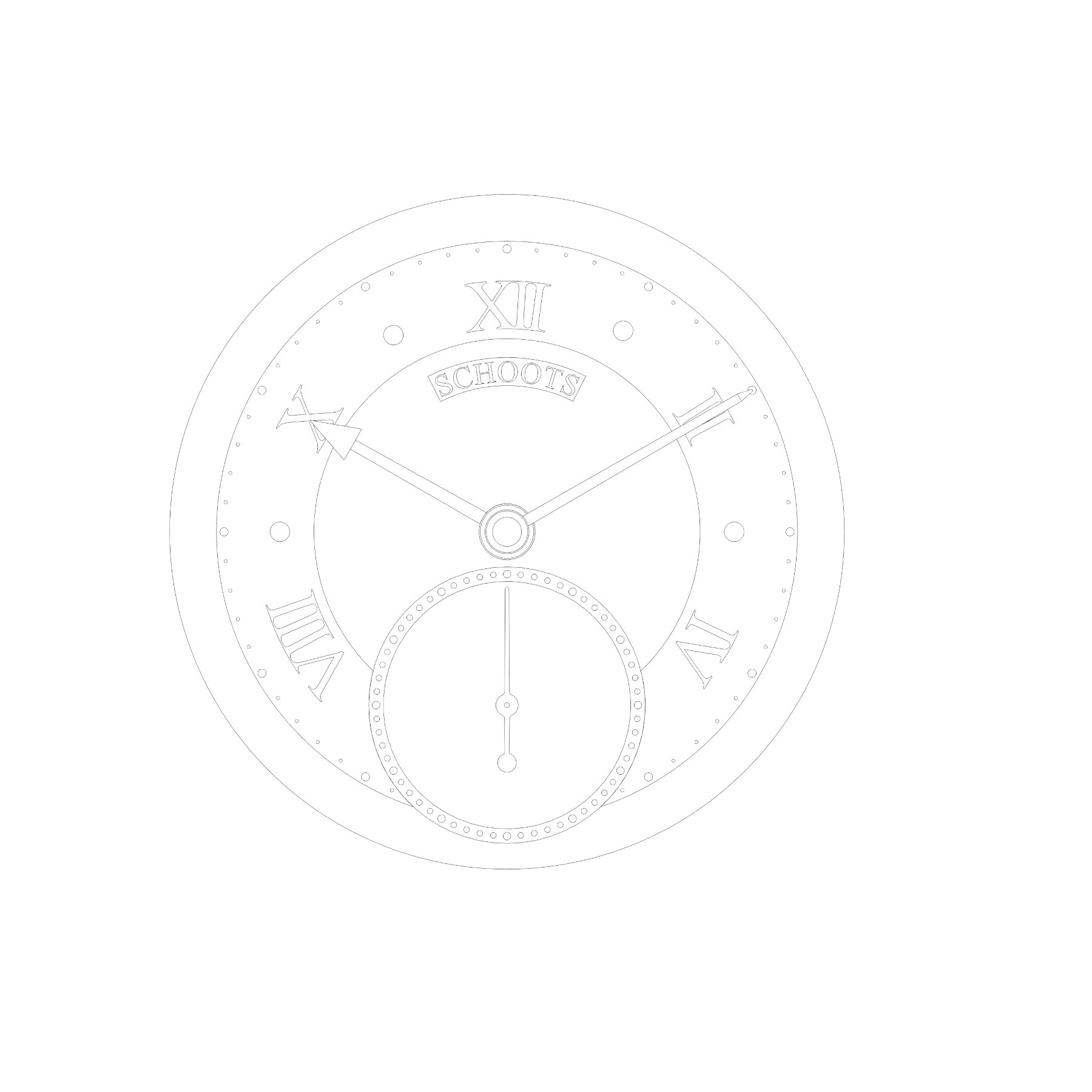

Reuben Schoots: Every component that is made in-house for Series Two has been redesigned. Beginning with the dial, which boasts enhanced proportions, improved legibility and is now made from silver. There are various finishing techniques used throughout the dial. There is a blend of guilloche, circular graining, straight graining and frosted finishes, the silver has also been flame-whitened to produce a bright matte white appearance, which produces a pleasing contrast with the chapter rings and hands. The hour hand now features a 3D sculpted arrowhead tip (see at the end of the story).

The movement architecture has been reimagined. I placed a large emphasis on creating intriguing 3D geometry throughout the bridges, cocks and plates. The central steel cock, holds the centre wheel on display, emphasising the wheel and drawing the eye toward the centre of the movement, whilst the multi-layered bridges and cocks create a sense of depth.

The inclusion of a beryllium copper crown wheel cap, with its warm copper tones, really brings out the subtle warm yellows and greens that I love in the surrounding German silver and polished and flame-blued steel.

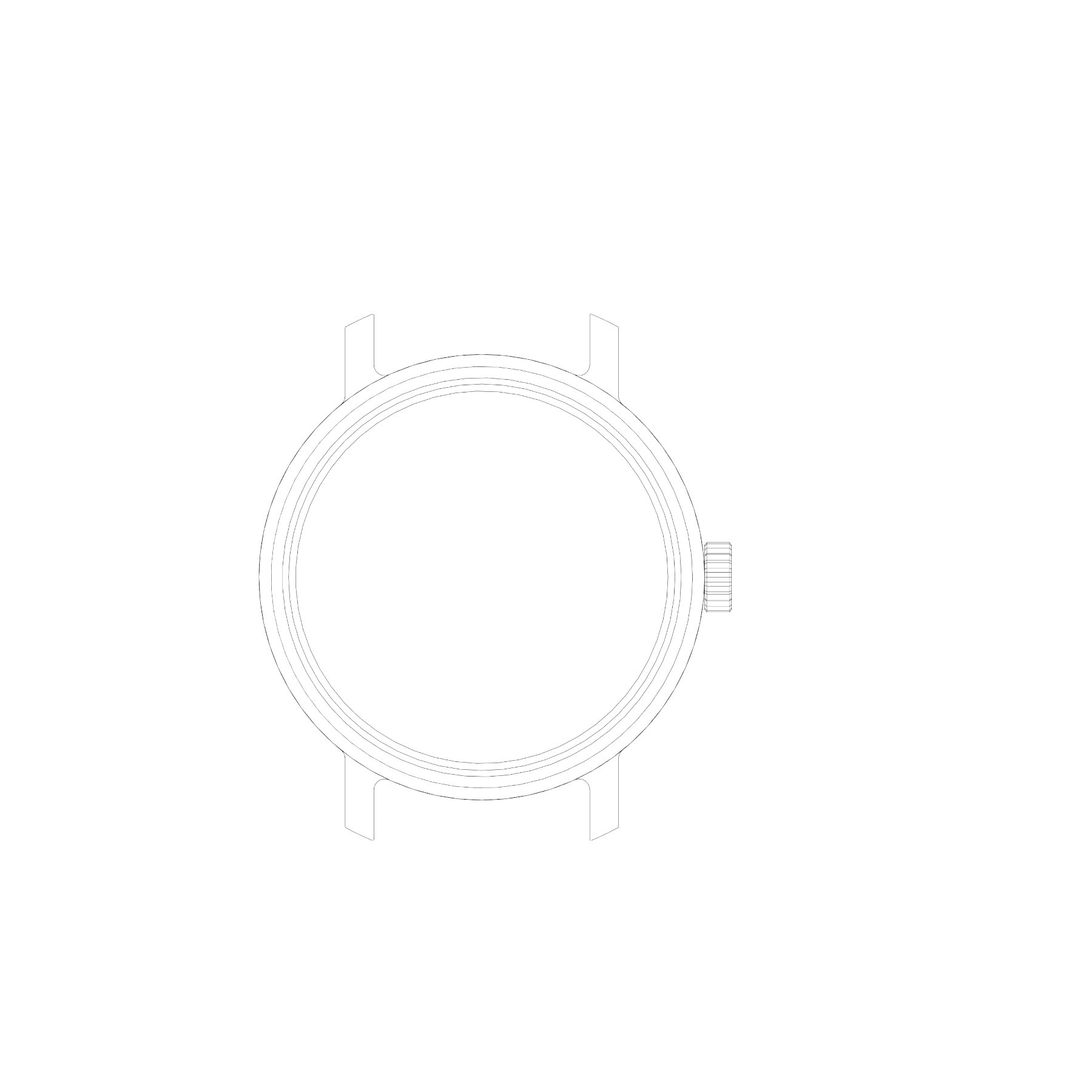

The classically inspired Series Two case is made from 316L stainless steel and has a 41.5mm diameter, a 49mm lug-to-lug and is 9.8mm thick, excluding the sapphire crystals. Bringing case-making in-house has been one of my major focuses for Series Two. A variety of tools and fixtures have been made as well as an entirely new set of skills learned. The Series Two case has been redesigned from the ground up. New lugs, new bezel, new case body, new case back and a new crown. I worked incredibly hard on this.

Did you use an existing base movement for the Series One, and now for the Series Two, or at least some known calculations for positions of essential parts?

Yes, I began with a base movement. Some readers may not know that my entire focus is centred around the goal of making as much of the watch as possible, here in my workshop. I go to great lengths to ensure I am constantly pushing towards this goal as I derive significant pleasure and meaning from making individual components from raw materials. As such, Series Two only retains the wheel train and keyless winding works from the base movement.

For reference and transparency, which I believe are important, these are the major components & assemblies I designed and made from raw materials for Series Two:

- Mainplate

- Barrel bridge

- Wheel train bridge

- Centre wheel steel cock

- Pallet fork & escape wheel cock

- Balance cock

- Crown wheel cap

- Crown wheel

- All movement screws

- Ratchet Pawl

- Click spring

- Balance Wheel

- Hour, minute and seconds hands

- Case

- Crown

- Dial

- Chapter ring

- Subsidiary seconds ring

- Nameplate

If to be put into perspective, how much more work is done in-house for the Series Two, compared to the Series One?

It was my goal to double the amount of labour I personally put into each Series Two watch in comparison to Series One. At this stage, it will be quite a bit more than double. This was a goal of mine, in order to push myself ever closer to my ultimate goal of designing, making and finishing every component of my wristwatches right here in my Canberra workshop. I like to imagine the idea of raw materials coming in one door and finished mechanical wristwatches going out the other.

Much of this additional work not only comes from the additional components that are being made in-house, the most notable of which are the mainplate, all case components, the crown, as well as some movement components, but it is also the fact that each and every component has been redesigned in a way that demands more from me as a maker, at every stage from design to machining and finishing

What were the biggest challenges in designing the watch?

The dial… proportions, material selection and finishing techniques. The overall design of the watch has been continually evolving since its inception. This is a bittersweet freedom of an Independent Watchmaker. Sweet as one can truly create the watch of their dreams, bitter as this can create considerable additional work! The dial is just so important and I cannot settle for less than my best work.

What were the biggest challenges in the construction of the watch?

I am profoundly grateful for the skill of watchmaking that I have acquired through hands-on experience. Yet, I cannot overlook the reality that being self-taught poses one of the most formidable challenges in my craft.

● The mainplate. With close to 100 critical dimensions and tolerances, this part, albeit large, is challenging to make, as there are just so many opportunities for things to go wrong. You really have to line up your dominoes perfectly.

● The watch case, bezel, and caseback have been designed and refined to achieve a balance of form and function. I did not expect it would take nine fully made prototypes to find this balance. Seeing something as a 3D model just isn’t the same as putting the watch case on the wrist. The case is made from three main components: the main case body, the bezel, and the caseback. Together they must be worn comfortably on the wrist, seal to the atmosphere, fit the movement correctly, have a perfectly aligned winding hole for the crown, friction fit for the sapphire crystals front and back, be of optimal thickness, and, of course, it must also meet my aesthetic requirements.

I’m sure there’s plenty more to tell about it, so feel free to share your thoughts!

I would like to share just how wonderful it is that I have the opportunity to pursue this dream of watchmaking. I would encourage anybody who is on the fence about pursuing their dream, to just go out and do it. Go all in and make it work. It only takes a brief reflection on our own mortality for us to realise that the time is now. I would like to thank my great mentors; George Daniels via his exceptional book ‘Watchmaking’, Lindsay Drabsch for sharing his wealth of knowledge in machine and tool making, and my supportive and encouraging wife, parents, family and friends. I am so excited to bring the first pieces from Series Two to completion.

For more information on Reuben Schoots and his watchmaking adventures, please visit his Instagram account or ReubenSchoots.com