“Simplicity is the Ultimate Sophistication” For Giulio Papi, the Master of Complications at APRP

Or when Giulio Papi quotes Leonardo da Vinci as a compass guiding his trajectory…

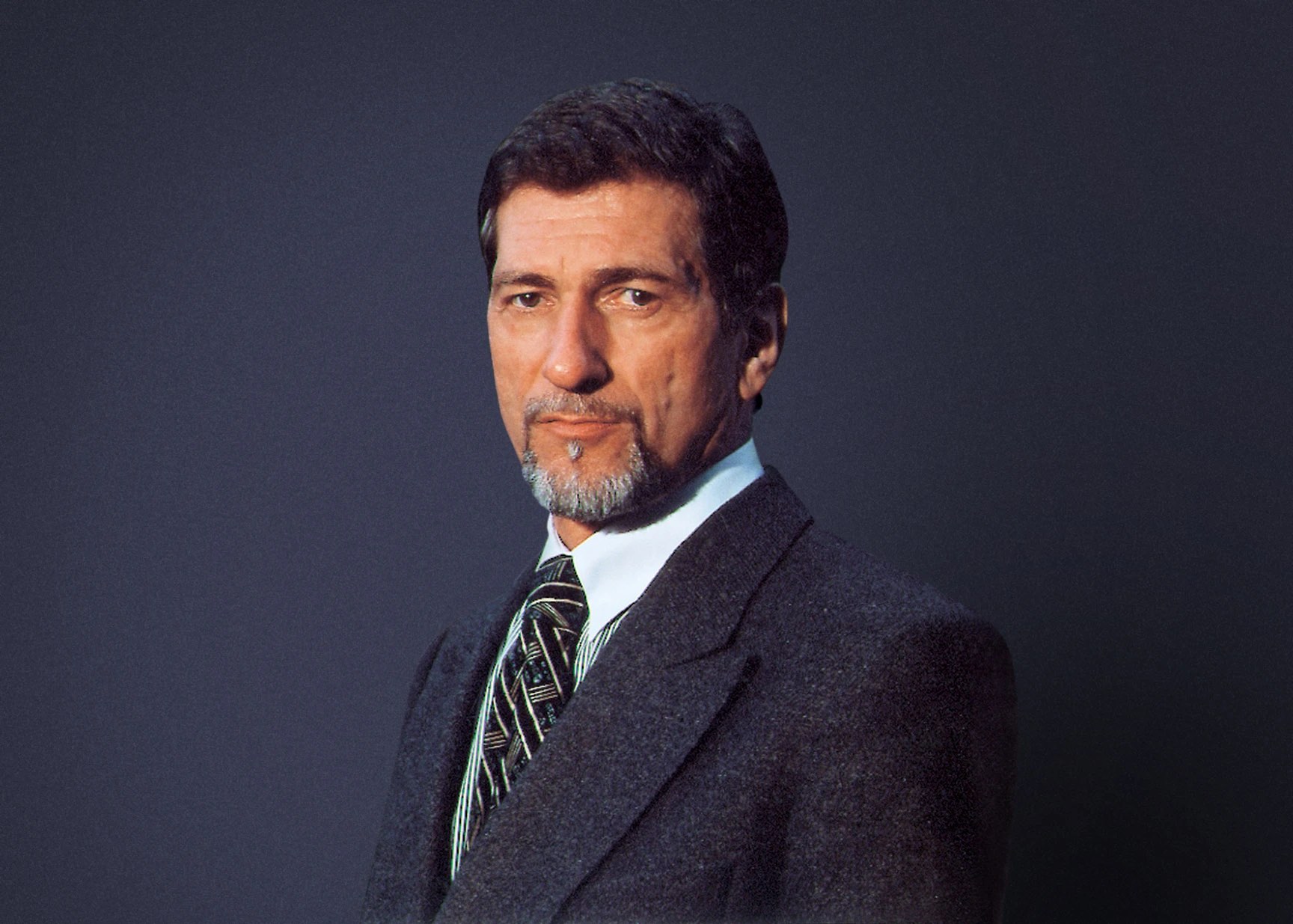

Aficionados regard watch brands as the stars of the show, all the more so when they present complicated or very complicated pieces. Upstream, there are other stars, the minds that conceive, design, and rethink watchmaking micromechanics in depth. Giulio Papi is one of those, and the mere mention of his name instantly sparks excitement among collectors. We interview the designer-inventor – how can we best describe him? – a modest man with a legendary reputation.

Papi is now the Technical Director of Audemars Piguet, Le Locle. The remarkable architecture of the manufacture, located on a promontory overlooking the city and mirroring the topography of Le Brassus (hotel included), is a contemporary sentinel of the brand’s history and home to 200 employees. Before arriving here, Papi’s path was marked by several stages, all characterised by a reflection process and, in truth, by simplicity. “Renaud Papi was not born to become a legend, but to work on complications,” comments the watchmaker who initially teamed up with Dominique Renaud to found the company in 1986.

Production of complications, but with modern tools

“Up until the mid-1980s, complicated wristwatches were very rare, and they all shared one thing in common. Brands bought complicated movements – blanks – produced until the 1930s; these were dismantled, refurbished and finished, but it took an enormous amount of work and a lot of experience to get the movement done and fitted before the watch could be sold.”

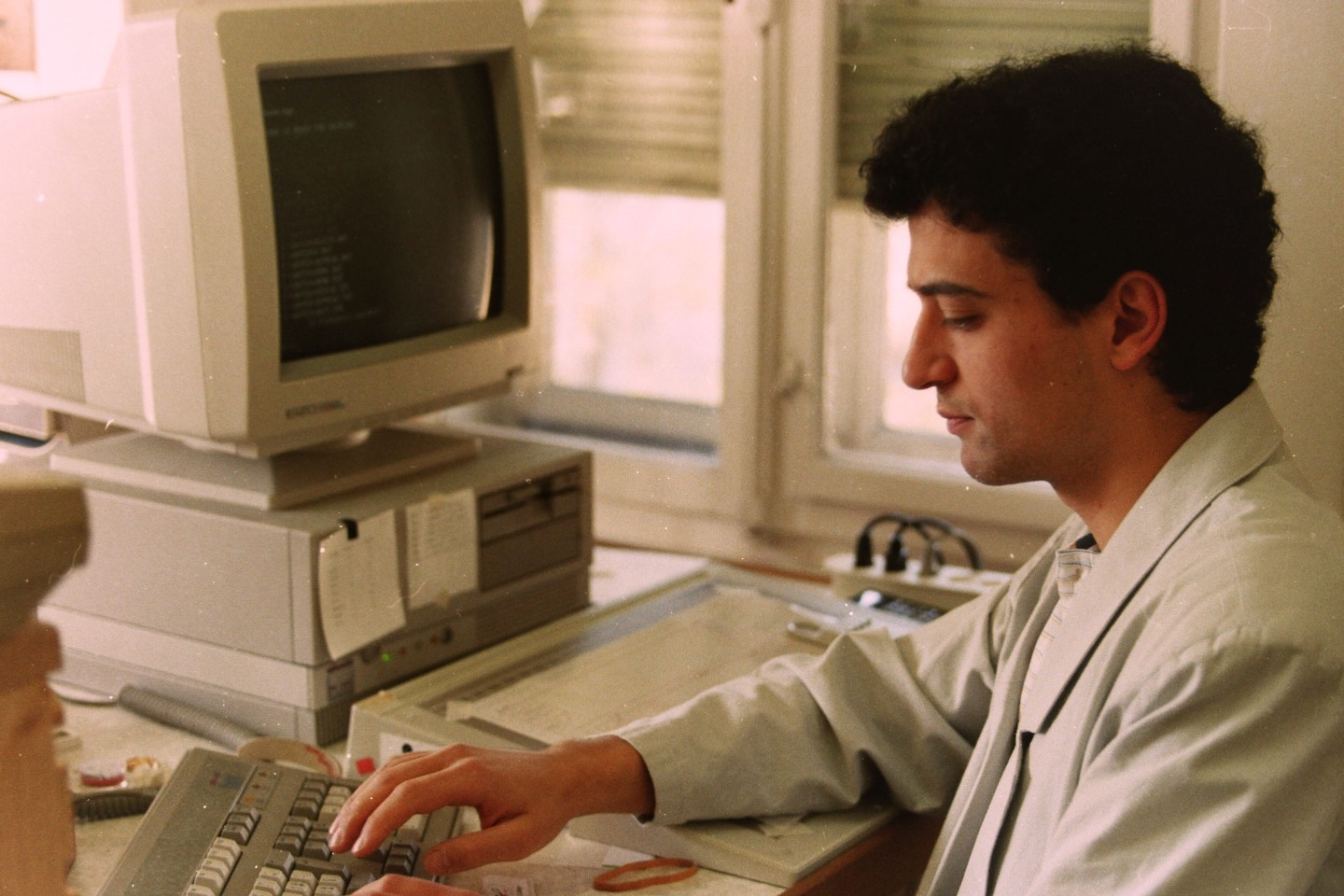

Using this straightforward premise, Giulio Papi and Dominique Renaud, then both at Audemars Piguet, concluded that they could launch an R&D unit specialising in the production of complications. The unit was equipped with the leading technologies of the day: numerically controlled machines (CNC), computers, etc. “I was also trained as an analyst-programmer, so I developed a CAD programme (current CAD solutions did not exist at the time), which allowed us to get started.” Much more efficient than the slide ruler and the manually calculated plans used for decades…

This also marked the beginning of an adventure for another leading figure regarded as a ‘lord’ of watchmaking: Günter Blümlein. The boss of IWC (and Jaeger-LeCoultre) ordered a modular Repetition mechanism from Renaud & Papi in April 1986, alongside the skeleton movements that the two partners considered their core business, a very fashionable style at the time, made exclusively by hand. “No one wanted them! So we decided to go for the Minute Repeater.”

Received with enthusiasm, Renaud & Papi worked on another modular Minute Repeater system, which Blümlein took on immediately, but this time for Jaeger-LeCoultre (the two brands were controlled by Mannesmann VDO under the name LMH – Les Manufactures Horlogères, before their acquisition by Richemont in 2000).

A landmark project: the relaunch of A. Lange & Söhne

At that time, the watch industry lacked suppliers for components used in Grandes Complications. In Schaffhausen, IWC had already started to address the problem by equipping itself with modern technologies, such as electrical discharge machining (spark erosion). This was to be a driving force for Renaud & Papi: they then decided to sell R&D services and to create their manufacture of high-end complications in 1989. Their demands were high: “We wanted very high degrees of finishing. But for that, we had to set up the company from scratch equipping ourselves with CNCs, recruiting mechanics, training finishers, etc…” Compared to blank movements, the jump to complications was enormous, but Blümlein understood the scope of their project. That same year, he signed a contract with Renaud & Papi (R&P) for a landmark project: the revival of A. Lange & Söhne.

A personal anecdote: I was the first journalist to be invited by Günter Blümlein to Glashütte in 1994 to celebrate the rebirth of a legend. The restoration of A. Lange & Söhne to its former glory not only marked Blümlein’s personal contribution to German reunification, but it symbolised the reawakening of the region’s great watchmaking tradition.

Audemars Piguet and Renaud & Papi: the start of the partnership

The next step was an encounter with Georges-Henri Meylan in 1992, who managed Audemars Piguet with Steve Urquhart – the first in charge of the manufacture and the second in sales. “Setting up a factory is expensive, and there were no investors then.” Meylan made them an offer: Audemars Piguet would allocate the funding but retain 52% of Renaud & Papi in return. Nothing could be more natural for Giulio Papi and Dominique Renaud, who had worked at AP from 1984 to 1986. “We said OK, but you are the bosses. We just want to work with modern technologies. It suited us well; we loved developing complications. At that time, AP was still working with an approach rooted in methods of the 1930s. We, on the other hand, now had modern production tools”.

This was when everything changed: rather than relying on “blanks” to develop a wrist complication, R&P started creating wristwatch-sized complications from scratch without replicating pocket-watch movements in smaller dimensions. “We developed new mechanical solutions by making certain components, such as levers, more reliable. That was our recipe for success.”

Coincidentally R&P also expressed a strong interest in new materials and colours. “Georges-Henri Meylan was not interested.” And then Richard Mille – well-known to Giulio Papi and Dominique Renaud – entered the scene. “He left the brand and told us: I need lightness and shock resistance. You have to remove anything heavy. Richard Mille wanted to launch its own production and position itself in the automotive world.” This is how R&P began collaborating with Richard Mille, offering him solutions such as a selector on the crown to activate the time setting and the winding mechanism. “We were inspired by steering wheel controls, which had just made their appearance at that time.” The innovative and ergonomic development reflected the spirit of R&P: to get away from traditional solutions, giving them reliability and contemporary use. We know how the Richard Mille saga unfolds, which continues even today with R&P.

A talent pool

Richard Mille is important, but let’s not forget all the other partners. R&P is also behind many heavyweight names in the independent watchmaking scene. Robert Greubel and Stephen Forsey, for example, who worked with Giulio Papi, left the company in 2000 to start their eponymous brand. Andreas Strehler, the Grönefeld brothers, Peter Speake Marin, Christophe Claret, Carole Forestier Kasapi, Anthony de Haas (A. Lange & Söhne)… “They all learned a lot with me; and the opposite is also true!”

At this point, R&P consolidated another step with Audemars Piguet. “The fusion was natural and logical.” This is how APRP (Audemars Piguet Renaud Papi) was born, even if Dominique Renaud had left the company at that time. From this moment, APRP started producing complicated movements for many brands. Chanel and Parmigiani Fleurier, for instance, but also historical partners such as Richard Mille and, of course, Audemars Piguet.

The Grande Complication Universelle: Giulio Papi’s vision of complications

Giulio Papi is the man behind the Grande Complication Universelle, a creation of which he is proud and which illustrates the essence of his philosophy. “I strove for simplicity in the grand complication. It looks like a chronograph, but you have to add the Grande Sonnerie, a split-seconds chronograph, a tourbillon, a perpetual calendar, and a semi-Gregorian calendar, among others. But the hour and minute hands are still positioned traditionally in the centre. What changes is the way of animating these complications.”

True to his credo, the correction of the indications is extremely easy to use: “Just go back if there is an error in the display. No need to redo the whole cycle again,” as is the case with most watches of this complexity. And despite its impressive mechanical content, this watch measures only 42mm in diameter, is shock resistant, waterproof, in short, designed for daily wear. Does it mark a first in watchmaking? “The Universelle of AP is one of the most complicated watches in existence. It also delivers one of the best sounds in the category of sonneries, with its soundboard that projects sound to a distance of 35 centimetres.”

Guilio Papi likes to quote Leonardo da Vinci, his reference, who claimed that “Simplicity is The Ultimate Sophistication”.

The partnership with Audemars Piguet advanced again in 2018 when Audemars Piguet expressed its wish to buy out Giulio Papi’s stake in the joint venture. A question of image, no doubt, and the need to lock down the company’s production capacities. “If everyone is happy, then it’s OK,” says Papi, who shares a history with the brand of no fewer than 145 jointly developed complications, “the largest database of complications in watchmaking history!”

What advice would Giulio Papi give to collectors today when the watch market – complications, iconic models – is in full swing with auctions and inflated prices for some of them? “Buy something that excites you!” Sound advice from somebody who has touched on every complication imaginable.

And on that topic… What is there left to develop in this area?

Complication but simplification

For Giulio Papi, the direction is clear: certain existing functions can still be improved and mechanised to make them easier to use and adjust. The Grande Complication Universelle is a reference for future developments. “We are going to work in this direction at Audemars Piguet now. Grand complications, yes, of all types, but in thinner cases and simpler to use. This is the trend, the spirit of today”. After years of unwearable, oversized watches, Giulio Papi hasn’t finished surprising us and is preparing a new chapter in the history of complication watches. Stay tuned.

2 responses

I didn’t know R&P were involved in the launch of Lange, very interesting! Is there any more information on what exactly R&P contributed to Lange’s first calibres, and did they have any input into the later Datograph, for example?

Congrats on a very comprehensive article about this legendary atelier of watchmaking.