5 Things I Discovered When Visiting Raketa in Russia (And How Different it is from Switzerland)

Forget about the clinical Swiss manufactures... This is soulful.

Not so long ago we talked to you about Raketa and a pretty cool watch the brand launched, a tribute to the famous Polar exploration watches done in the early 1970s. But that wasn’t all. With a flight ticket in my hand and Back in the U.S.SR. from The Beatles in my headphones (I know, total cliché), I flew to Saint Petersburg and visited the Raketa movement manufacture. I’ve visited well over 40 watch manufactures in my career, mostly in Switzerland and Germany… But nothing that can compare to what I saw in Russia. A truly unique experience, an eye-opener, fascinating, unusual, emotional, nostalgic, touching, sometimes slightly melancholic but always human.

Raketa…

The Raketa Watch Factory, founded by Emperor Peter the Great in 1721, is the oldest factory still active today in Russia. Created first to cut semi-precious stones to adorn the Royal family’s palaces (and then known as the Imperial Lapidary Factory), it was, under the Soviet era, transformed into a watchmaking company. First by delivering jewel bearings for manufactures, then becoming a movements and watches factory.

As of 1949, watches were produced under the names Zvezda and Pobeda by the Petrodvorets Watch Factory in Saint Petersburg. The major turning point occurred in 1961 when the brand Raketa was launched. On 13 April 1961, Yuri Gagarin made the first manned flight in outer space onboard rocket Vostok 1. In honour of this achievement, the Petrodvorets Watch Factory named its watches “Rocket” Raketa in Russian. From the early 1960s until the late 1980s, Raketa would be one of the world’s leading watch manufactures. Raketa watches were produced for the Red Army, the Soviet Navy and for North Pole expeditions, as well as for civilians. In the 1970s the factory produced about five million mechanical watches per year.

The dissolution of the USSR and uncontrolled privatizations were dramatic for Russia’s production facilities, including the local watchmaking industry, which was almost decimated. Still, for the last few years now, a team of passionate people, led by British, French and Swiss entrepreneurs has decided to restore Raketa to its former glory – maybe not in terms of numbers, but in terms of watchmaking, with true “Made in Russia” watches, including entire movements made in-house.

And here are five unusual facts I’ve discovered when visiting Raketa in Saint Petersburg, Russia.

1 – There’s a Choir… Yes, A Choir!

We start with something that has nothing to do with watchmaking, but that says a lot about what to expect when visiting Raketa. Some European watch brands might have their own soccer/football teams or a council that organises trips for employees’ children… Raketa has something else, something a bit outdated, extremely unusual, very nostalgic and touching at the same time: a choir.

While we were visiting the ateliers, David Henderson-Stewart, the man at the head of Raketa now, took his phone out of his pocket and gave a call to one of the women you see in the video above, a sort of matriarch who represents the retired employees of the manufacture. And in less than an hour, she managed to gather over 10 of her sisters in arms, all dressed up in traditional costumes and ready to sing in the in-house choir. Clearly, this isn’t something you’ll see in Switzerland…

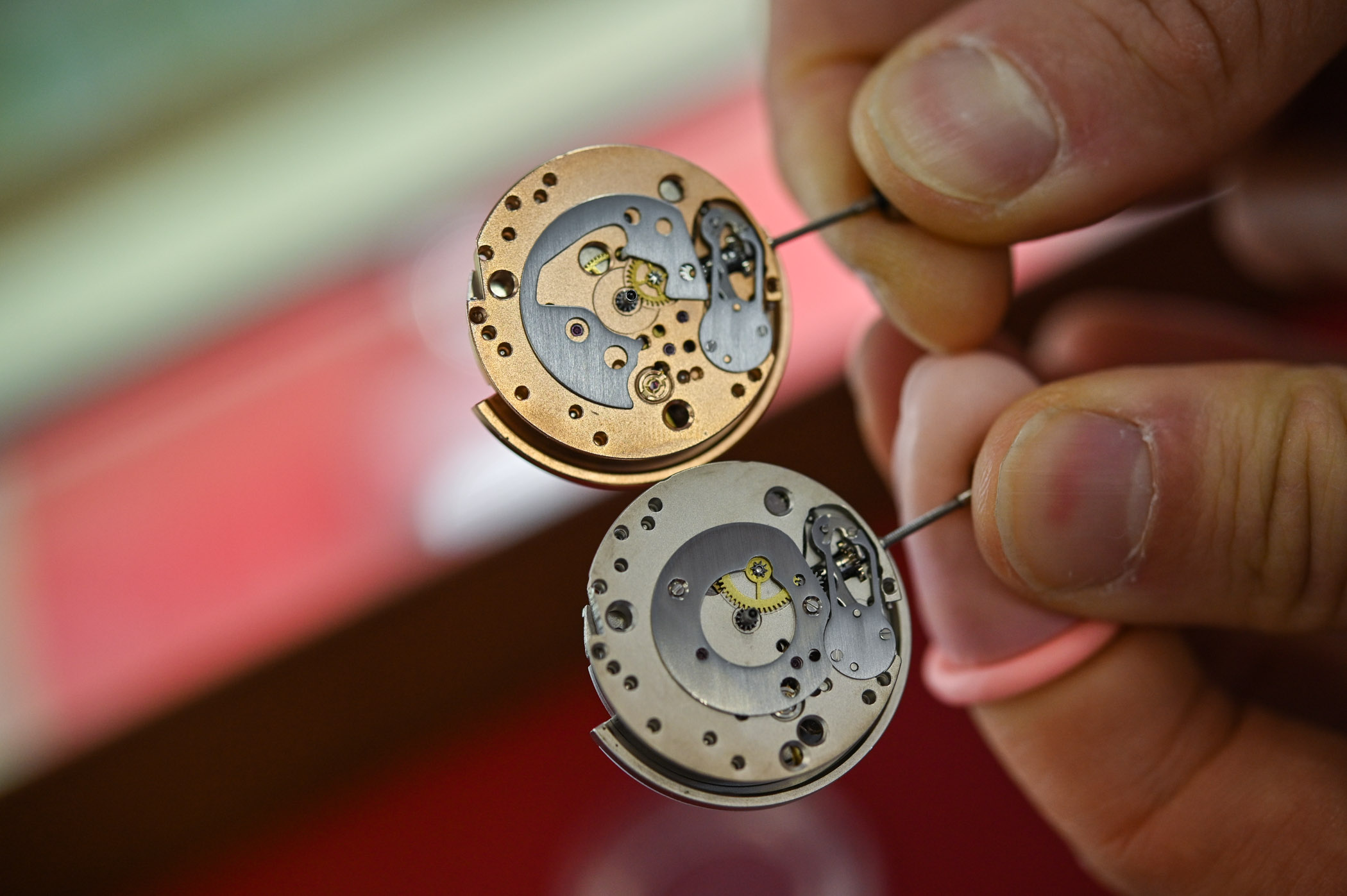

2 – Almost all the movement parts are done in-house

The concept of in-house or manufacture movement has been a great argument for Swiss and German brands for the past two decades. A sort of must-have for any brand that wants to demonstrate its savoir-faire and gain respect on a horological level. However… this in-house notion is vague and isn’t clearly defined by fixed rules and requirements. In fact, almost no brand can claim to make a movement 100% internally. Some parts are almost always out-sourced (for obvious reasons). However, Raketa isn’t located in the Swiss mountains and doesn’t have access to the same network as Swiss brands… That means finding solutions.

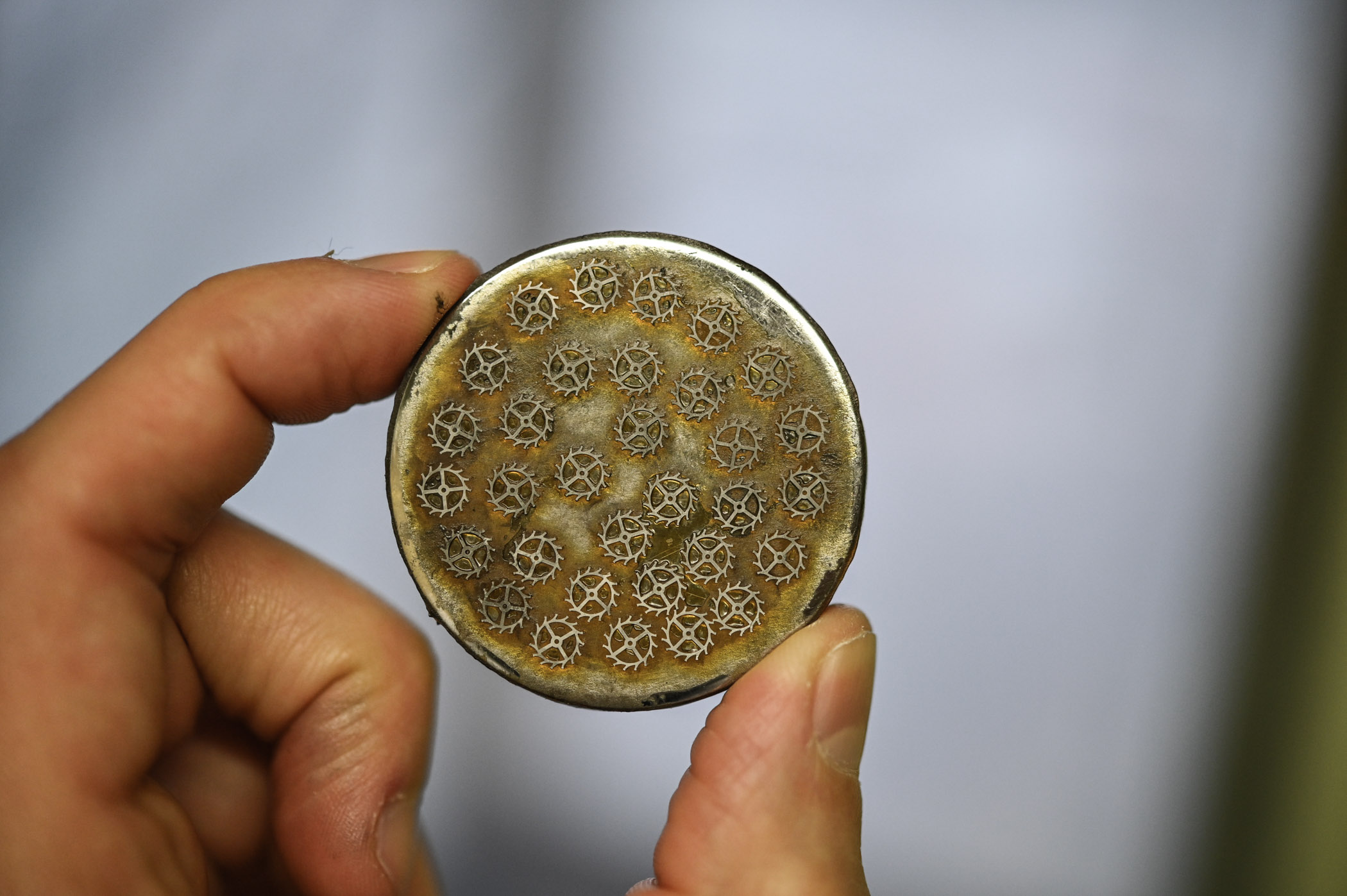

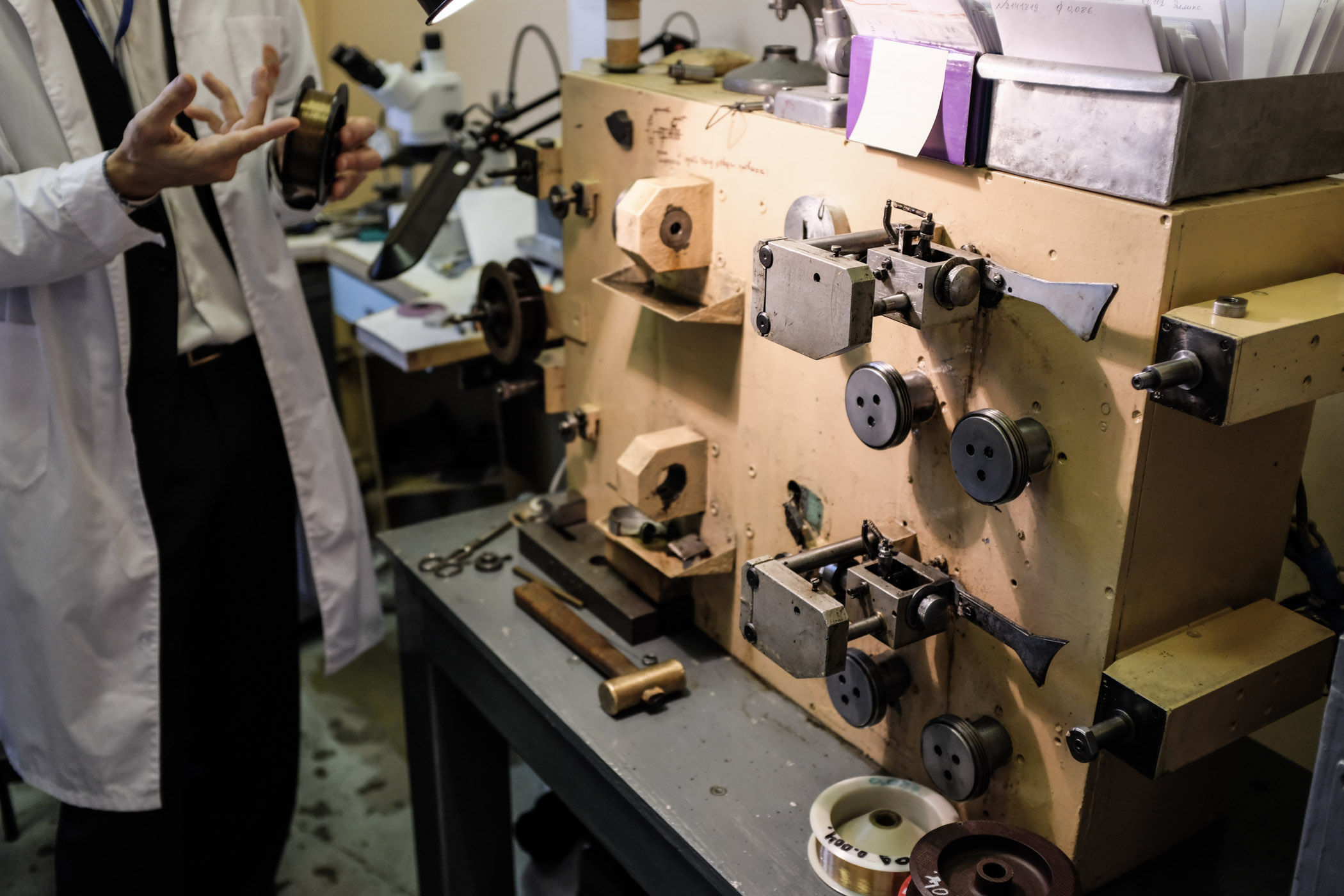

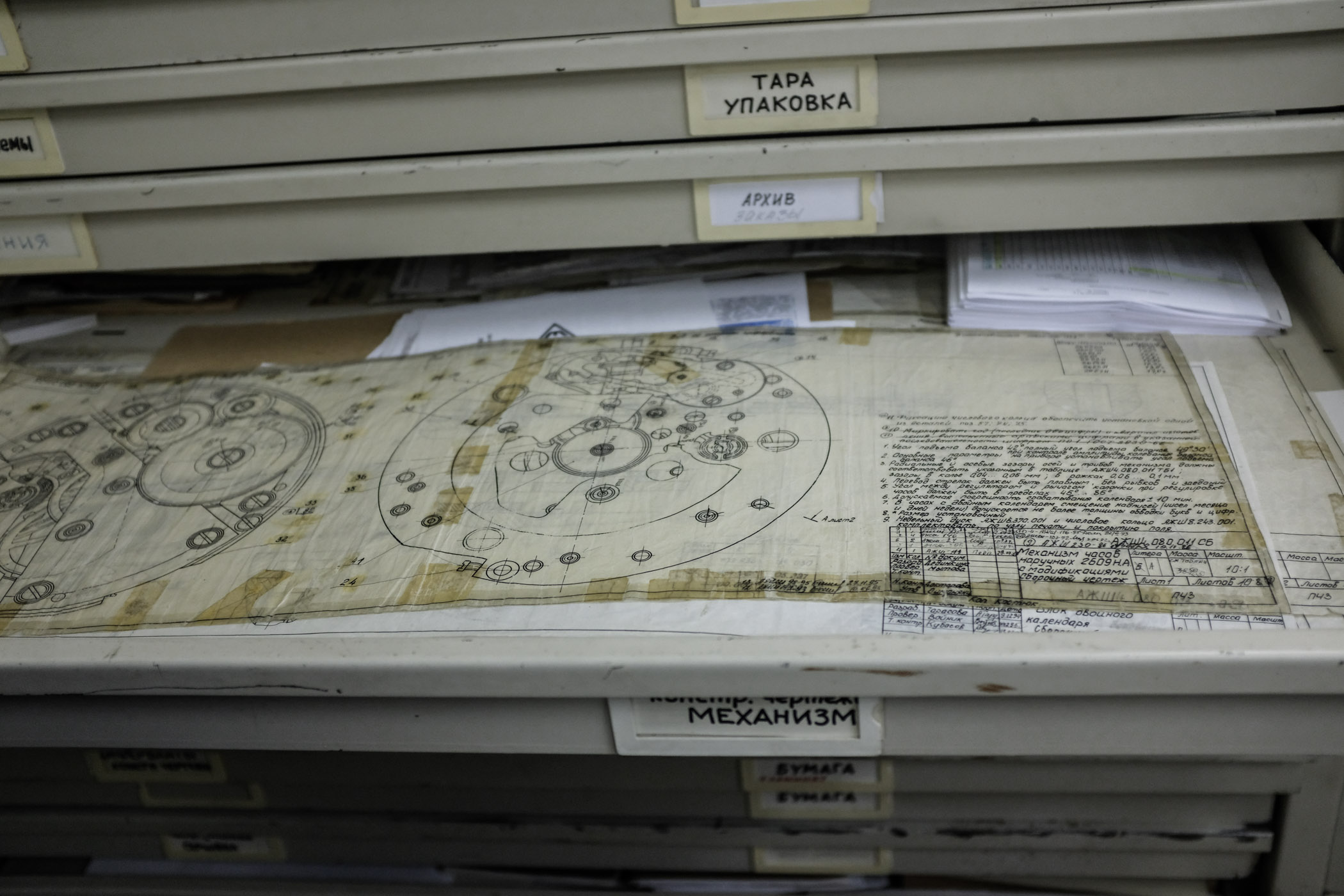

One important factor with Raketa is that the movements are almost entirely produced internally, with the exception of certain parts (such as jewels or ball bearings for instance). Plates, bridges, screws, wheels, springs, oscillating weights, balances or even escape wheels are produced in this manufacture, in the most traditional way. From raw material to finished product, everything is performed internally, even the plating or galvanisation of the parts that are done in a small atelier near the manufacture, by a lady with Ray-Ban glasses and a cigarette in her mouth – really… this is something special.

3 – And that includes the hairspring!

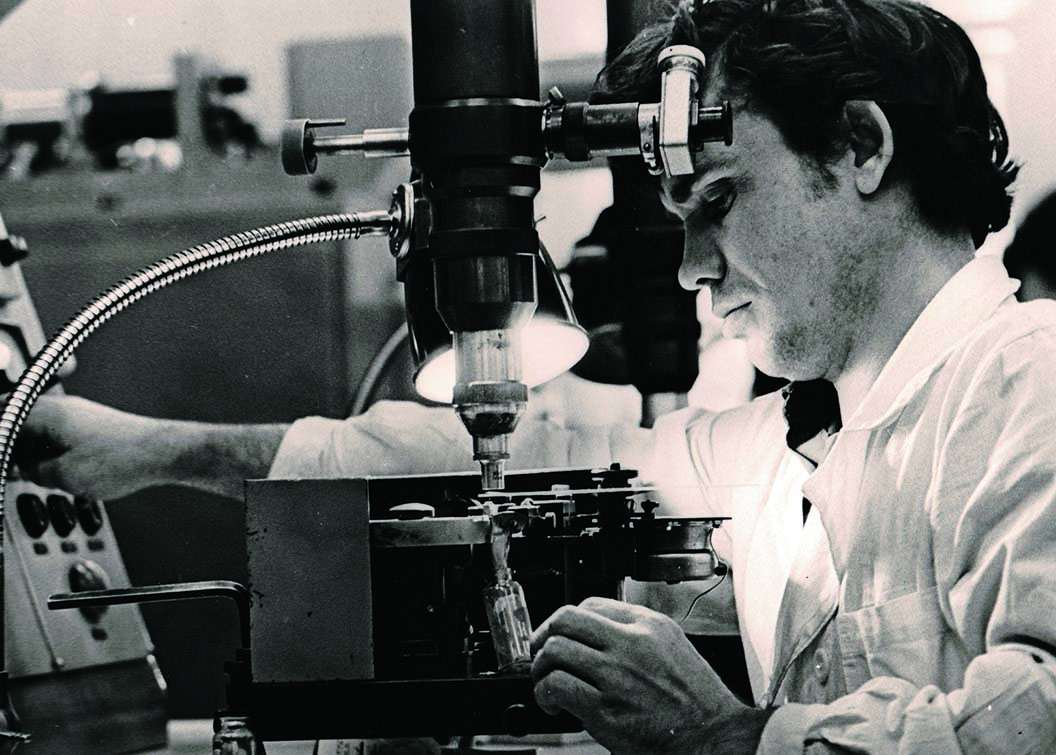

One of the most crucial parts of a watch movement is the hairspring, the small circular spring that allows the balance to move back and forth – in short, the beating heart of a watch. There are probably a handful of Swiss watch brands that craft hairsprings in-house, and another handful of external suppliers that supply the rest of the industry. Seeing them made in-house is quite exceptional since the production process is complex, time-consuming and requires multiple steps – drawing, rolling, cutting, coiling, pairing, pinning/soldering, poising and shaping the terminal curve (a process we explained in details here). That’s what it takes to transform a 1mm wire into a 60-micron concentric spring that will guarantee the precision of the watch.

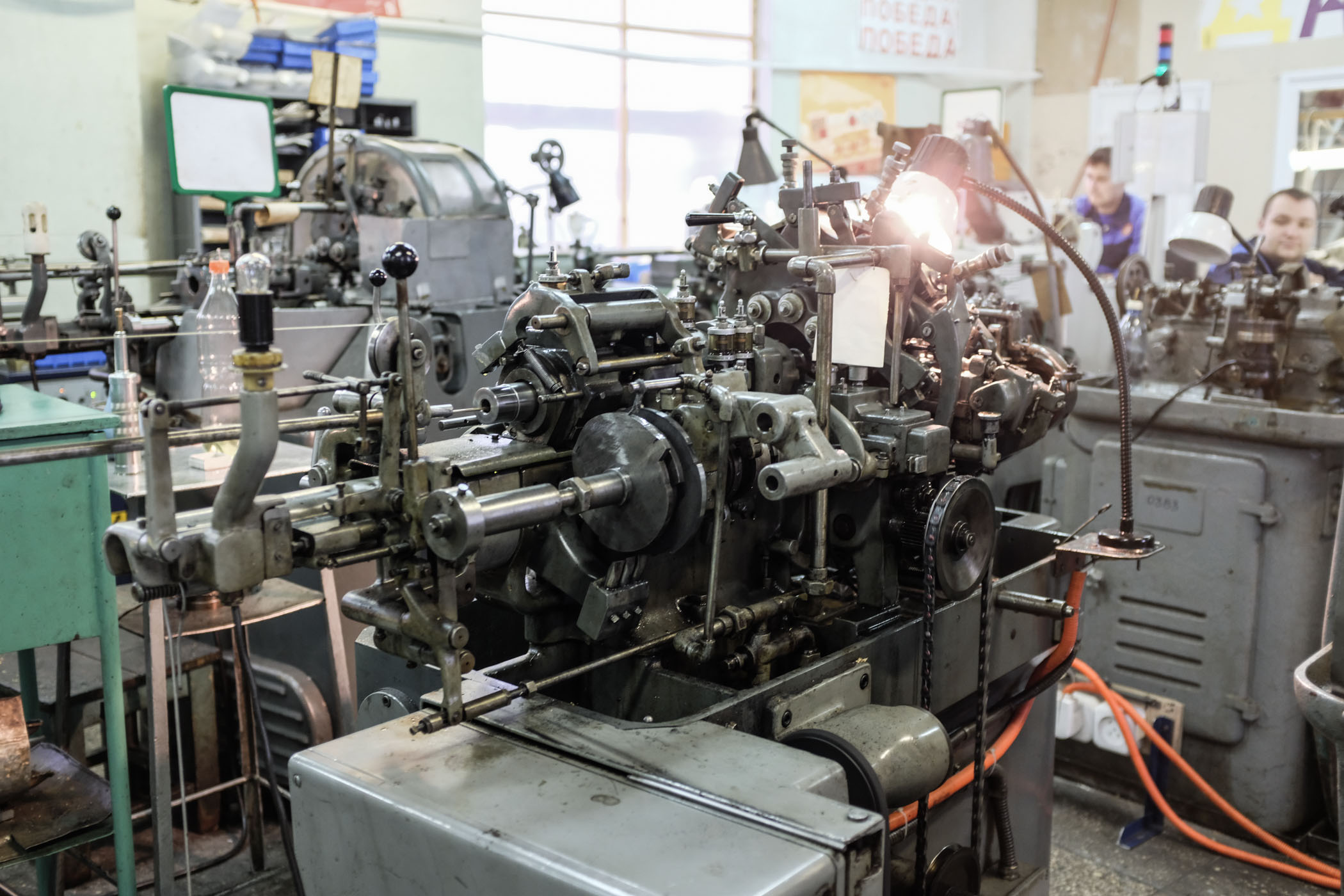

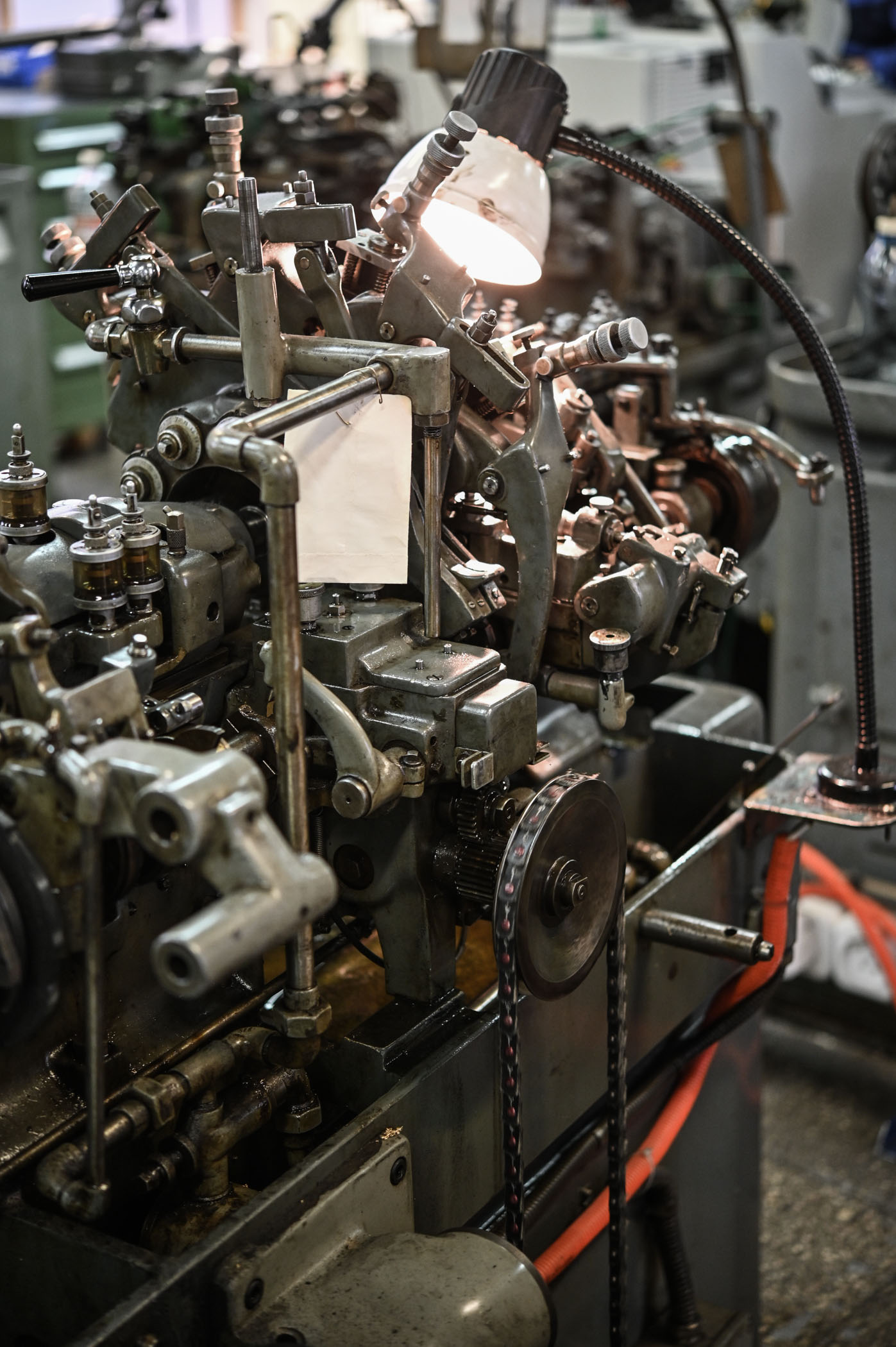

As mentioned, seeing this being performed in Swiss or German manufactures is already quite an event. But like the rest of the parts of the movement, Raketa makes its own hairsprings internally, the old-school way – no CNC, no laser-controlled tools, no ultra-advanced technology here. It is done with the means at their disposal (post-WWII machines), with a certain ingenuity and the experience of a one-hundred-year-old manufacture. If not cutting-edge, it is still remarkable.

4 – It’s a trip back in time

Forget about the clinical manufacture of IWC. Forget about the massive plants of Rolex or Patek Philippe. Forget about the rooms filled with dozens of CNC machines, as you’ll find in Chevenez, TAG Heuer’s movement manufacture. Forget about the ultra-advanced Master Chronometer laboratory developed by Omega. Forget about the beautiful yet modern ateliers of Armin Strom. Or the high-end skills performed at Breguet. Raketa reminds you what watchmaking was back in the 1940s or 1950s when women and men – and not computers – were crafting parts of a movement.

So certainly, visiting Raketa won’t be a refined, luxurious experience. However, it has something else, a soul, an outdated charm, a feeling of simplicity combined with ingenuity. Machines are old, full of oil and noisy. But they work, they are maintained so the parts can be produced and the movements assembled.

Visiting a manufacture in Switzerland or in Germany is something I’d recommend to anyone interested in watches. It’s a must in a collector’s life. And in the same vein, if you visit Russia one day, I can only recommend going to Saint Petersburg and visiting Raketa. It’s a once-in-a-lifetime opportunity and something you won’t forget.

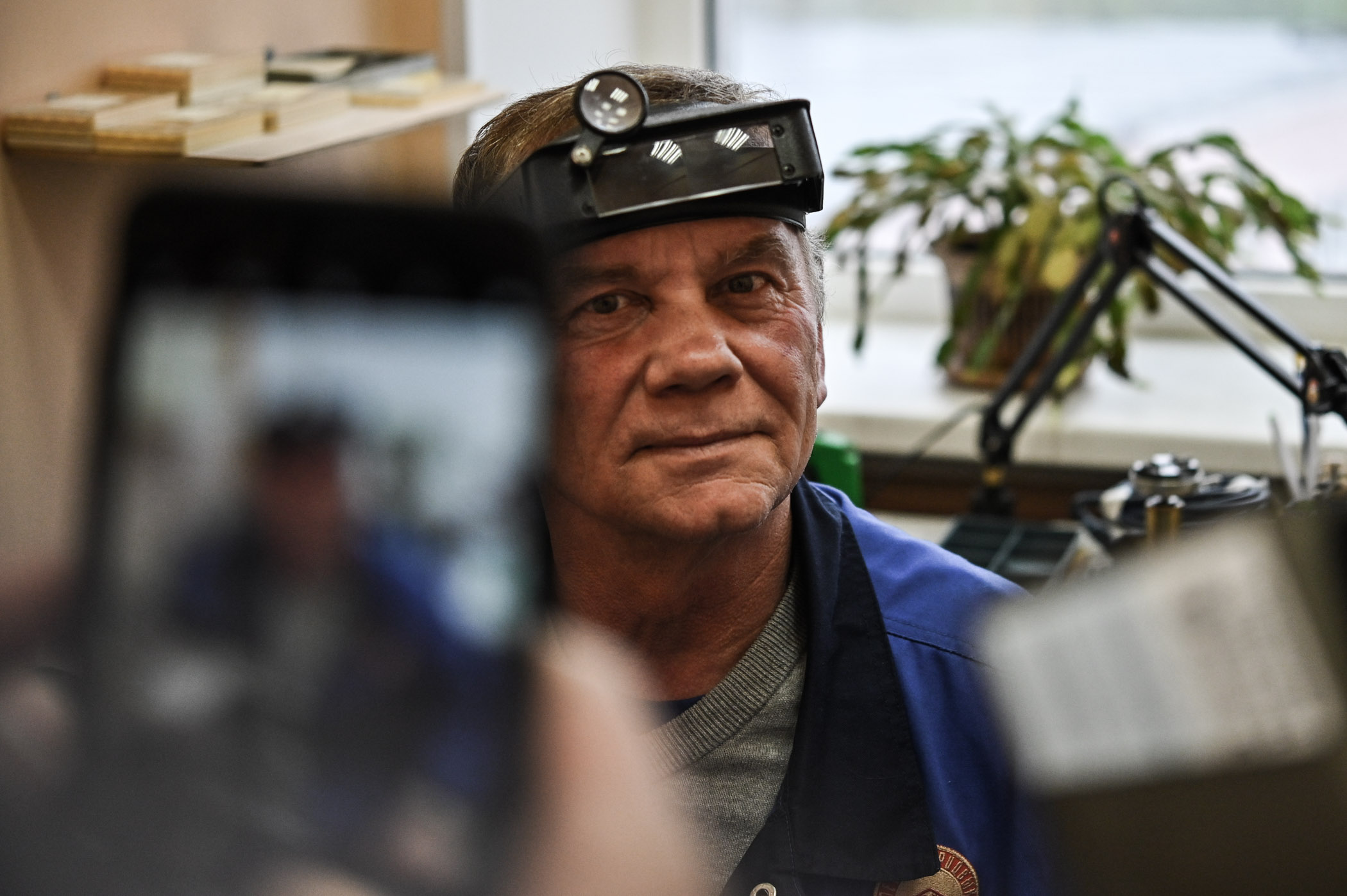

5 – It’s more human than anything else I’ve seen before

Last but not least… This is certainly the most human experience I’ve had when visiting a watch manufacture. The living memory of the brand is here, in the head and heart of the people that have worked there for decades and still make this possible today. No caption here, just some devoted employees who live for Russian watchmaking.

More details at raketa.com.

7 responses

What an excellent report Brice, and thank you for making this trip. I had no idea how Raketa watches were produced. Indeed very human and so different from the way the production is done in Europe.

Every time I read about Raketa, I am impressed by their dedication and it makes me want one. Thanks for the trip report. I’d love to visit one day.

Merci Brice for that stunning article! Years ago, my In-Laws offered me a Raketa (not any kind of Raketa, but the 50 years in Cosmos Gagarine’s Jubilee) Since then, I am fascinated by the brand’s history. Few years ago, and had the chance and the honor to visit the “design office” in Moscow, and I was really feeling privileged to receive some much informations about the Brand’s history and how it went through time… Reading now your article motivates me to visit the factory in St Pet’ while being back to Russia! Thanks again!

Check out a Chinese case maker’s factory. Squatting men, machinery whirring, dim lighting, etc.

I agree, Russian watches are totally different, I have had a few over the years. I have one I paid £7 for new about 40 years ago never serviced and still keeps good time, the others were not so great. They are never bland and still cheap enough to buy just to have something different.

Excellent idea to bring news from an old factory with a nostalgic appeal that still exists, despite the fierce competition in the watch industry.

As mentioned in the article by Brice Goulard, the company now belongs to a group of foreign investors, possibly with a partnership of the Russian government. Although the new owners brought new horizons to the watch brand, the sales price of the models seems to me somewhat expensive, vis-à-vis the competition of the low-middle luxury watch brands from Switzerland (Swatch Group) and Japan, specially Seiko.