SIHH 2017 – Ulysse Nardin InnoVision 2 (And Why It Makes Us Rethink The Future Of Mechanical Watchmaking)

SIHH 2017 – Ulysse Nardin is about to make some noise at its first SIHH, showing off some seriously cutting-edge technology. The watch you’re about to see is nothing like anything you’ve seen before. Every part of this watch boasts an innovation, whether we’re talking about the escapement, the display, the winding system or even the hands. Meet InnoVision 2, a concept watch featuring avant-garde innovations that will make us rethink the future of mechanical watchmaking.

Founded in 1846, Ulysse Nardin has a long tradition in the field of chronometry and is well known for manufacturing accurate marine chronometers. In the early 1980s, an encounter between Rolf W. Schnyder, a businessman and visionary, and Ludwig Oechslin, a brilliant horologist, turned this traditional manufacturer into one of the most innovative watch brands around. This partnership would yield several milestones in mechanical watchmaking history. Among these, the legendary Freak housing the innovative “dual direct escapement” with silicon escapement wheels. With it, Ulysse Nardin became not only the silicon pioneer of mechanical watchmaking but developed a brand new escapement – which remains a crowning glory for the most skillful and creative watchmakers.

The Ulysse Nardin R&D team did not stop with the Freak however. The brand’s research in the innovative use of new technologies and materials opened up amazing possibilities. Ulysse Nardin truly heralded a new era in mechanical watchmaking, using silicon, nickel and nickel-phosphorus (LIGA) or diamond, ‘DIAMonSIL’ (silicon covered with synthetic diamond) to shape components within avant-garde concepts. To support this forward-thinking strategy, Ulysse Nardin even created Sigatec in 2006 (together with Mimotec) which is involved in LIGA and DRIE technologies to manufacture components.

In 2007, the presentation of InnoVision 1 stunned connoisseurs, a concept watch that allowed Ulysse Nardin to demonstrate its technical capabilities with 10 innovations, 7 of which made it to production pieces.

This year the brand is attending SIHH for the first time, and so Ulysse Nardin is about to make some noise, bringing back the InnoVision concept – featuring no less than ten avant-garde innovations that may make us rethink the future of mechanical watchmaking, all gathered within a new “Freak” concept named InnoVision 2.

The design idea remains true to the original Freak: its revolving movement features a gear train and escapement rotating once every hour and showing the minutes. The case has no crown as the time can be adjusted by turning the bezel, while the movement can be hand-wound by turning the case back. But behind this somehow familiar look, the InnoVision 2 evidences the comprehensive expertise of Ulysse Nardin and its capacity to imagine alternative possibilities in designing new concepts and in using cutting-edge materials and technologies.

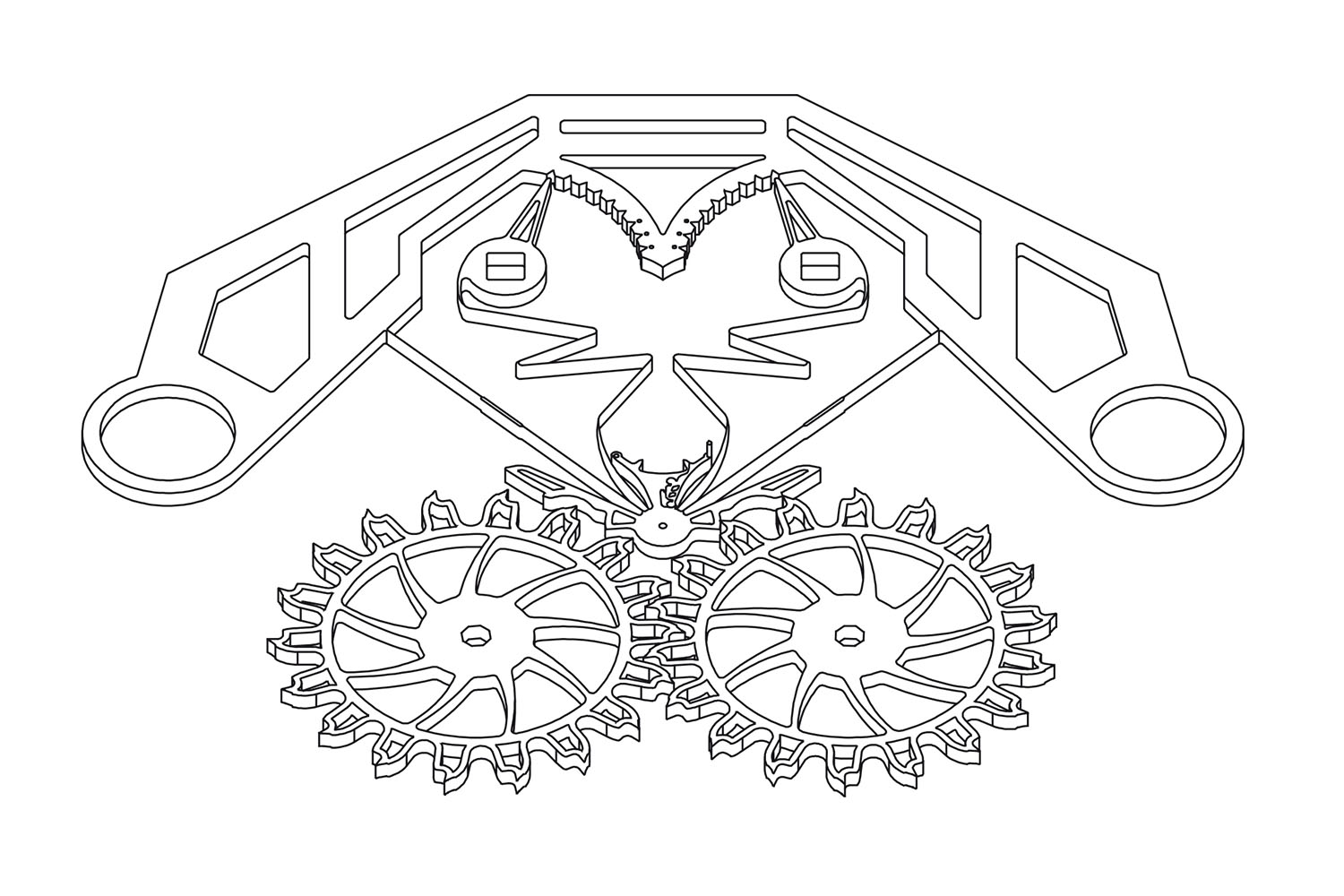

Innovation 1 – Dual Constant Escapement

The Dual Constant Escapement is a hybrid between the Dual direct escapement (2001) and the Ulysse Anchor Escapement (2014). Like in the Dual Direct escapement, which aims at improving efficiency, two escape wheels alternatively interact with a cleverly designed part with locking elements, to alternatively transmit impulses to the balance wheel. Like in the Ulysse Anchor escapement, it is using the potentialities offered by flexible silicon blades to create a sophisticated constant force escapement. A holy grail of watchmaking, constant force aims at achieving constant amplitude for the oscillator despite the waning torque provided by the barrel mainspring. The silicon part interacting with the 2 escape wheels is suspended (no staff hence no friction) by buckled blades that are alternatively tensioned by the mechanism before snapping back to provide constant impulses to the balance wheel (for more information on escapements read our technical perspective here).

Innovation 2 – Direct silicon bonding

An innovation in production technology, the strategic silicon component of the escapement involves silicon bonding as the complex, three dimensional shape of this part requires a two-part production process, which is unprecedented for small horological components. A vertical bond is created by compressing hydrophobic surfaces at process temperatures of between 1000 to 1200 degrees Celsius with the addition of oxygen.

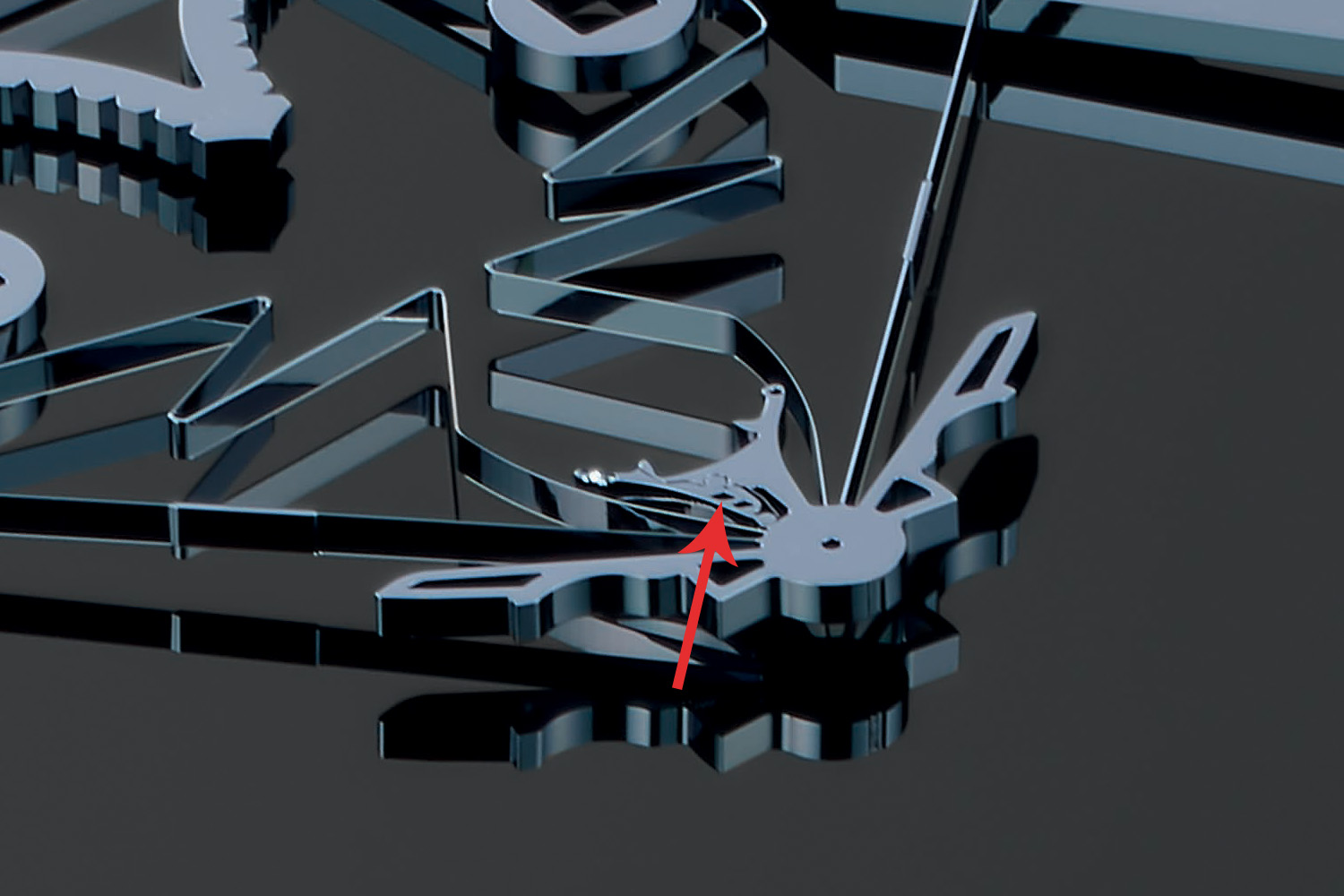

Innovation 3 – Silicon balance wheel with gold mass elements and stabilizing micro paddles

It is no surprise to see a silicon hairspring to regulate the InnoVision 2. Ulysse Nardin has been a pioneer in the field, taking advantage of the wide-ranging beneficial properties of the material: silicon is light, non-magnetic, corrosion- and shock-resistant and highly flexible despite its great hardness.

On the other hand, the new balance wheel is completely unprecedented, boasting really interesting characteristics. It is crafted in silicon to have a minimal mass at the center as its silicon body weighs only seven milligrams. The 4 adjustable gold UN anchor masses on the rim provide a high-moment of inertia. The paddle-shaped arms aim at maintaining constant oscillation by smoothing air turbulence. Altogether, this also allows the balance to be less sensitive to amplitude changes between horizontal and vertical positions.

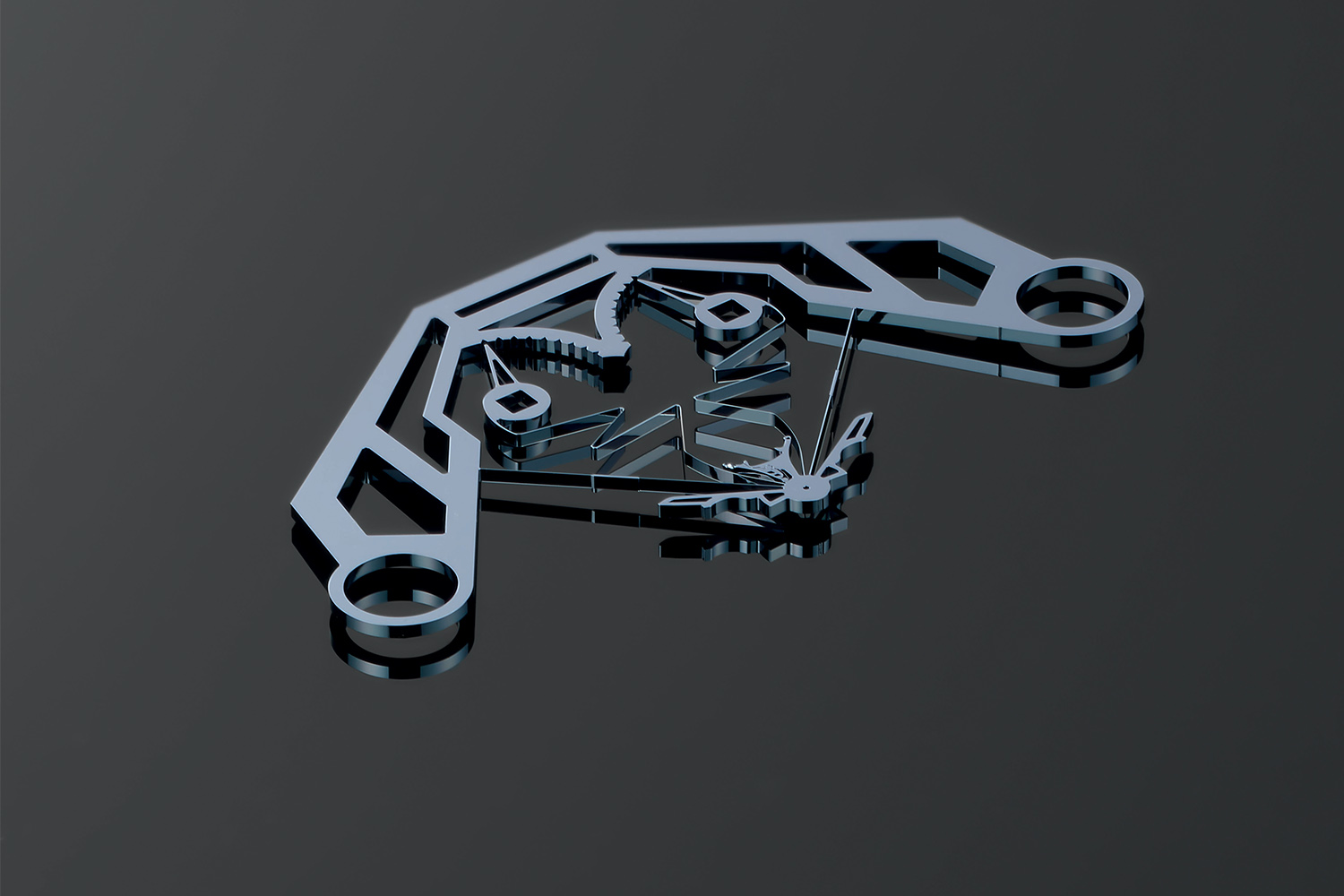

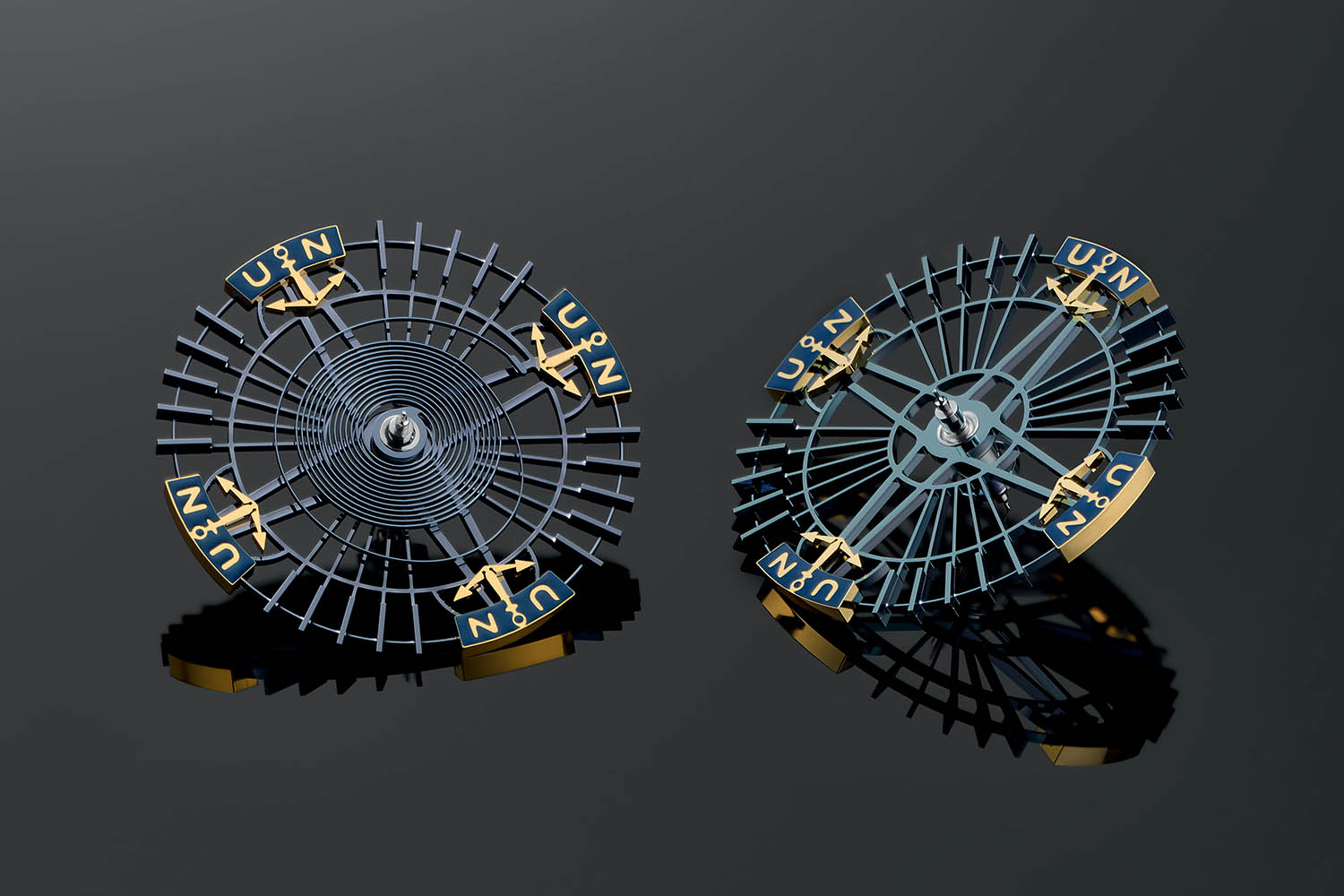

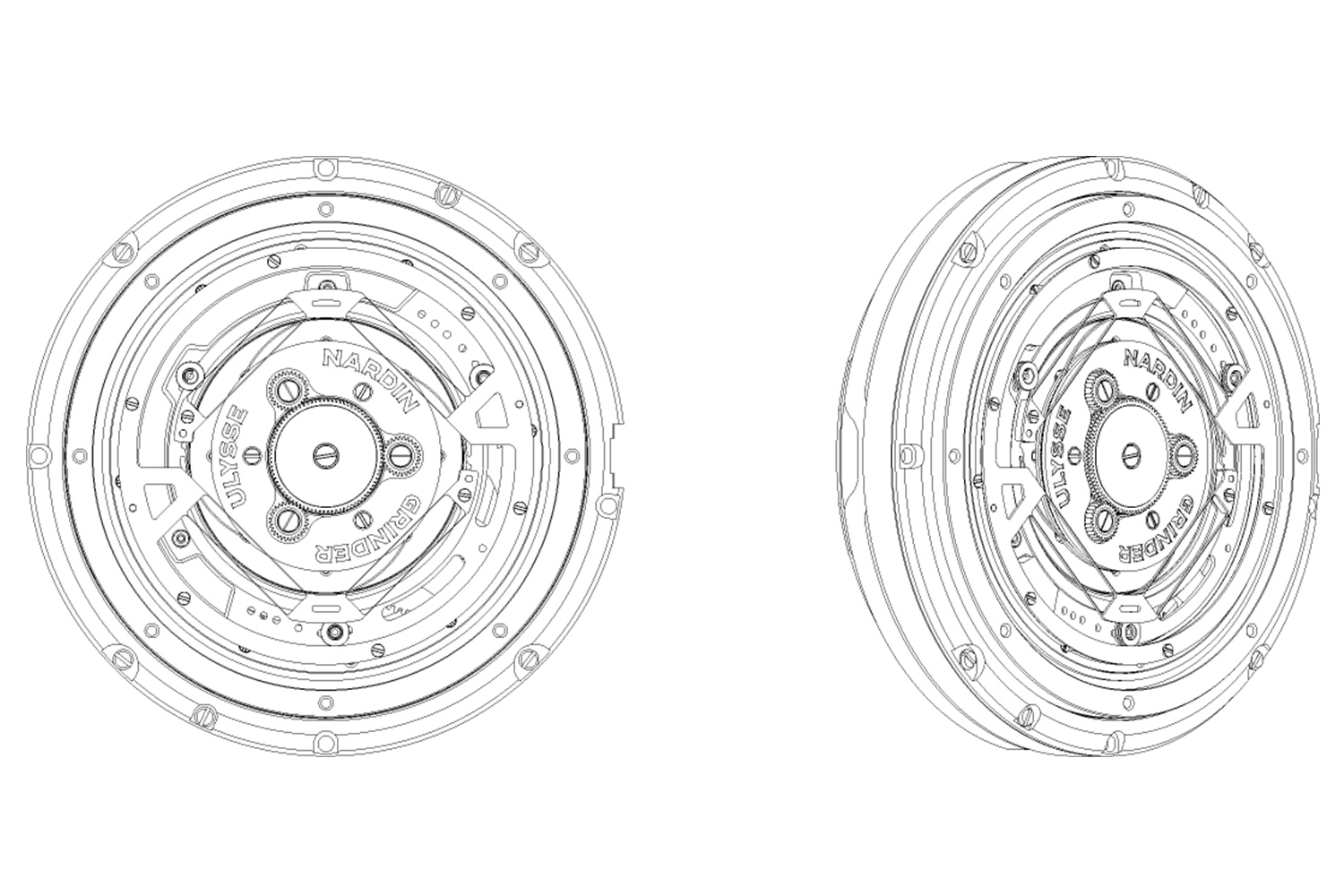

Innovation 4 – “Grinder” automatic winding system

Working on ways to optimize the function and efficiency of the automatic winding mechanism, the Ulysse Nardin R&D team has developed a completely new system dubbed “Grinder”. The focus has been to improve the degree of inefficient idling – in particular, “the dead angle” for which the traditional rotors are not winding the barrel resulting in a loss of energy.

Underneath a centrally located ball-bearing rotor, the “Grinder” architecture features three smaller ball-bearings, which operate on two pairs of springs in a filigree-shaped frame. The ring attached to this frame has four springy claws. Their small, hooked-shape free end engages with the winding wheel centered above the barrel. Each rotation of the oscillating weight makes the frame and the ring oscillate. This makes one or two of the four claws move the winding wheel, exploiting the tiniest amounts of kinetic energy.

Innovation 5 – Sapphire-coated silicium bridge

Thanks to a production process developed with EPFL Lausanne and Sigatec, the InnoVision 2’s elongated center wheel bridge is made in silicon coated with a one micrometer sapphire film. This does away with the need to set jewels in the bridge as its smooth sapphire surface offers optimal characteristics such as low friction with pivots, stability and durability!

Innovation 6 – 24-Karat hard gold wheels

The wheels of the Ulysse Nardin InnoVision 2 are produced by photolithographic LIGA technology with Mimotec. The ultra-precise manufacturing process involves a galvanic deposition stage that results in the creation of 24K hard gold wheels, a material which enhances the efficiency of the gear train.

Innovation 7 – Glass bridge with integrated shock protection for the balance wheel

Innovation in the field of anti-shock devices is not new to Ulysse Nardin, as seen with their Ulychoc concept to protect the balance wheel staff with a silicon spring replacing the traditional block, the setting, the jewel, the counterpivot and the spring (read our technical perspective about jewels here). For the InnoVision 2, Ulysse Nardin manufactures the balance cock itself and the entire integrated shock protection system from glass. Its glass coiled spring features superior flexibility, strength and frictional behavior.

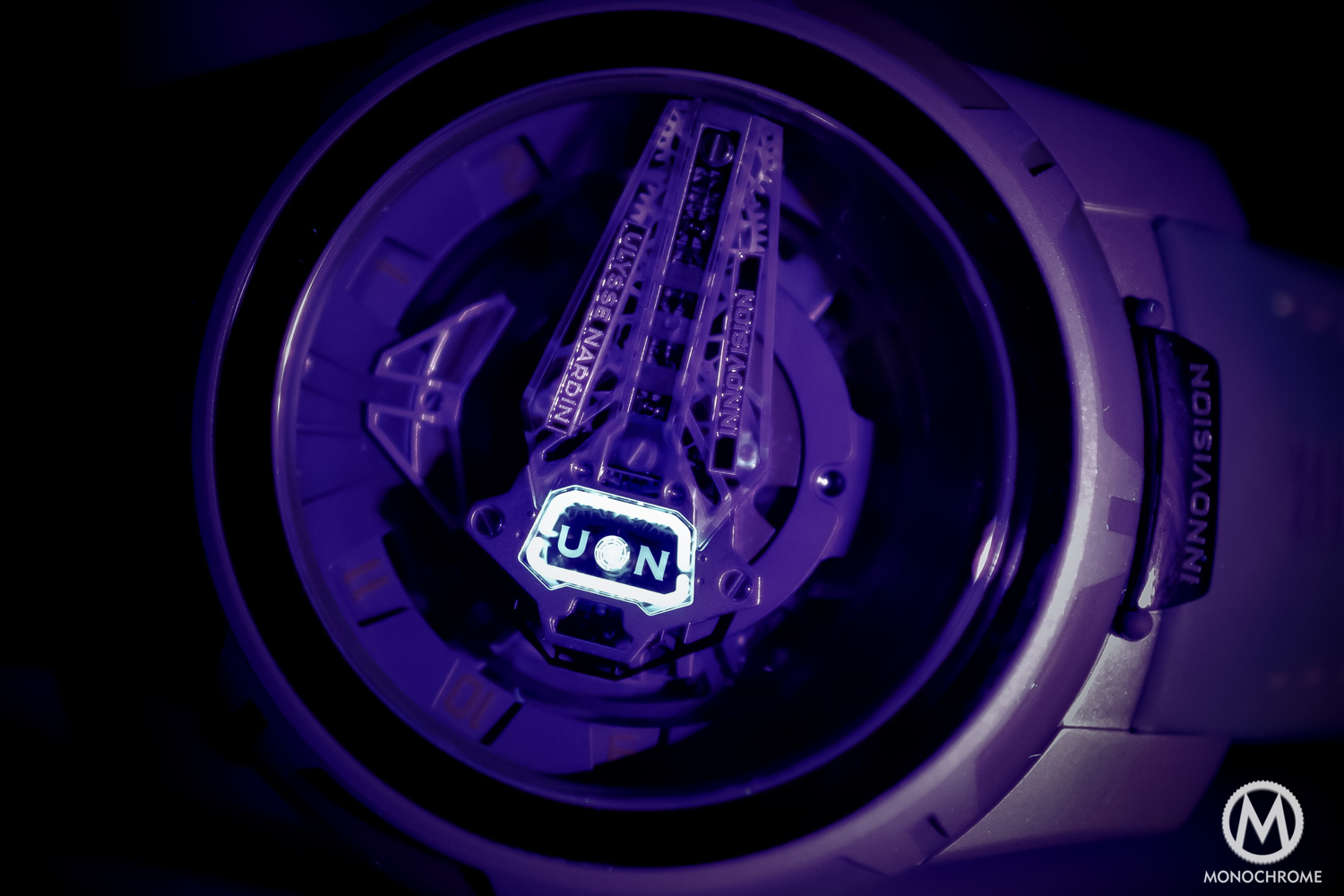

Innovation 8 – Super-LumiNova filled channels integrated into the glass balance wheel bridge

Manufacturing the InnoVision 2’s balance cock from transparent glass offered the opportunities to create channels within it and fill these with luminescent material glowing in the dark.

Innovation 9 – Eye-catching 1 – 11 and 13 – 23 time display

The InnoVision 2 also features an innovative time display. The digits to read the time are displayed through apertures and switch from 1-11 to 13-23 to differentiate day and night. A printed ring is moved twice a day directly by the barrel (which requires 15 minutes).

Innovation 10 – Three-dimensional glass minute hands

Alongside the innovative digital time display, the InnoVision 2 also features the emblematic “Freak” minute hand bearing the gear train. In the case of this watch, it is manufactured in glass using precision laser cutting and sits on a fine metal plate.

While we had the privilege to see the watch (too quickly unfortunately) shortly before the SIHH, it will deserve a stronger coverage later, with more technical insights, more macro photos and videos, in order for you to understand everything that is hidden in the concept. more details on ulysse-nardin.com.

2 responses

A great, high technical timepiece with useful innovations….No surprise it comes from UN.

I can’t wait to see more live pix – videos.

Regards,

slide68

A great innovative watch. But the INNOVATION 9 – EYE-CATCHING 1 – 11 AND 13 – 23 TIME DISPLAY is a copy of the one that was mounted years ago on the GRUEN Air Flight