A Guide To The Hairspring, A Crucial Part Of The Movement (Technology, Manufacturing Process, Future Developments)

Sprung to life: who manufactures Hairsprings? An industry perspective on this key component whose production is still shrouded in secrecy – Barely one centimeter in diameter, the hairspring is the beating heart of a watch movement. It is a strategic component in several respects. Manufacturing hairsprings is a complex process and the whole Swiss watch industry has been relying on one supplier, Swatch Group’s Nivarox… at least, until very recently!

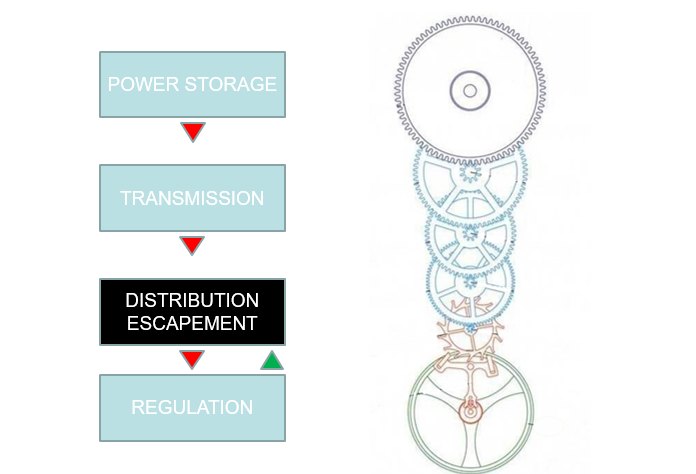

Christian Huygens is credited (by common consensus) with the invention of the first movement with a balance wheel and hairspring in 1675. Since then, the principles of the regulating organ of the watch have changed very little. The escapement gives impulses to the balance wheel. In return, it is regulated by the balance. The oscillations of the balance wheel regulate the flow of time: each swing of the balance allows the gear train to advance a set amount. Its role is similar to that of a pendulum in a clock. The extremely thin coiled hairspring ensures that the balance swings back and forth at a constant frequency.

The state of the industry

Nivarox (a company of the Swatch Group) has long been the inescapable supplier of hairsprings and assortments (escapement / regulator) for the Swiss watch industry. It remained the main supplier largely because no other firm emerged that could offer comparable quality at a competitive price and with the same production capacity. This dominant position however, and the assortment sourcing difficulties which arose during the boom of the industry in the early 2000s, led to the creation of alternative sources.

Manufacturing Process

Hairsprings are nowadays often made of iron-nickel alloys such as Nivarox, whose elasticity is almost unaffected by temperature. Nivarox is an acronym for Nicht Variabel Oxydfest (Non-Variable Non-Oxidizing). This alloy is in the same category as Invar, an alloy (FeNi36%) invented by Swiss Nobel prize winner Charles Edouard Guillaume.

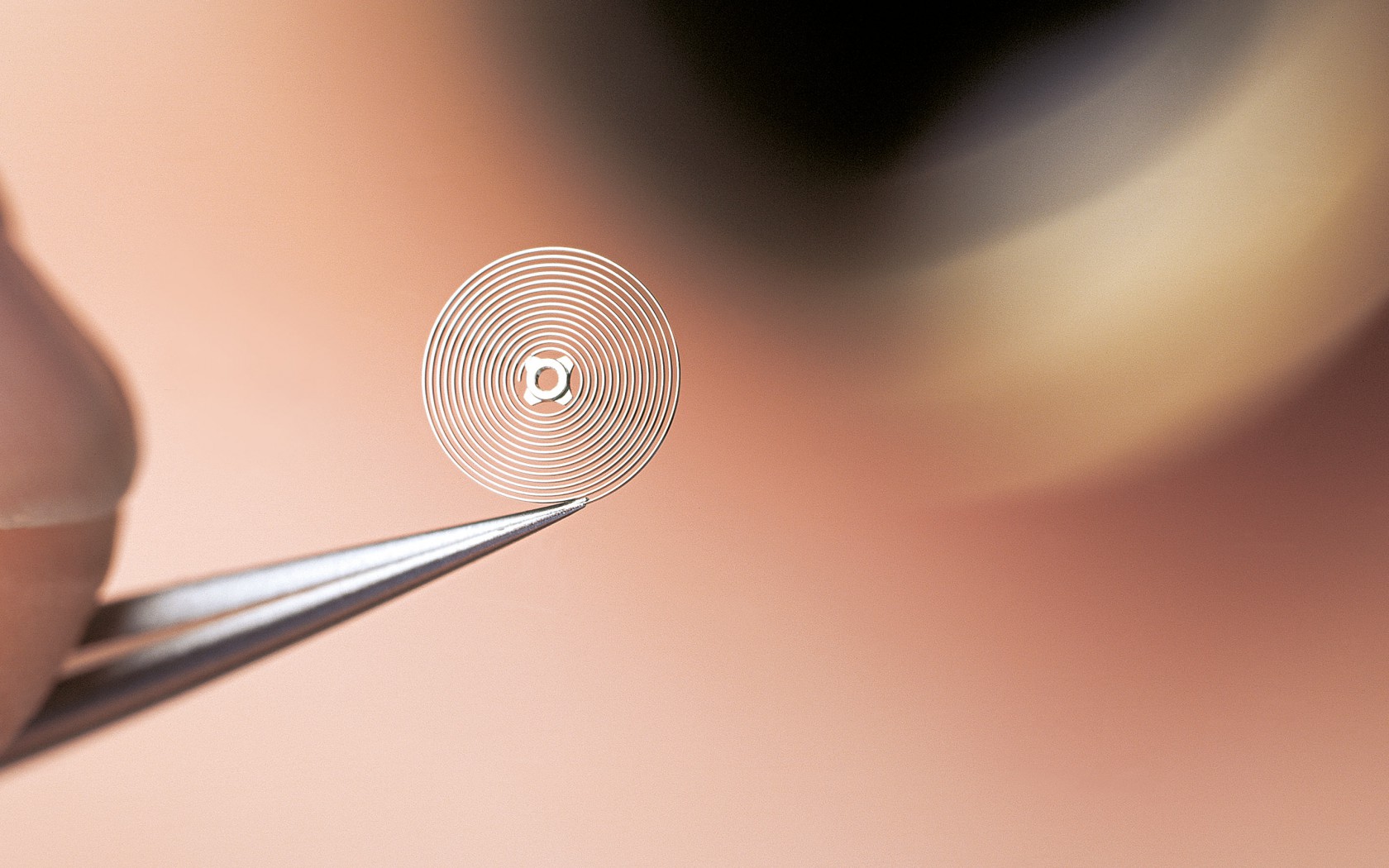

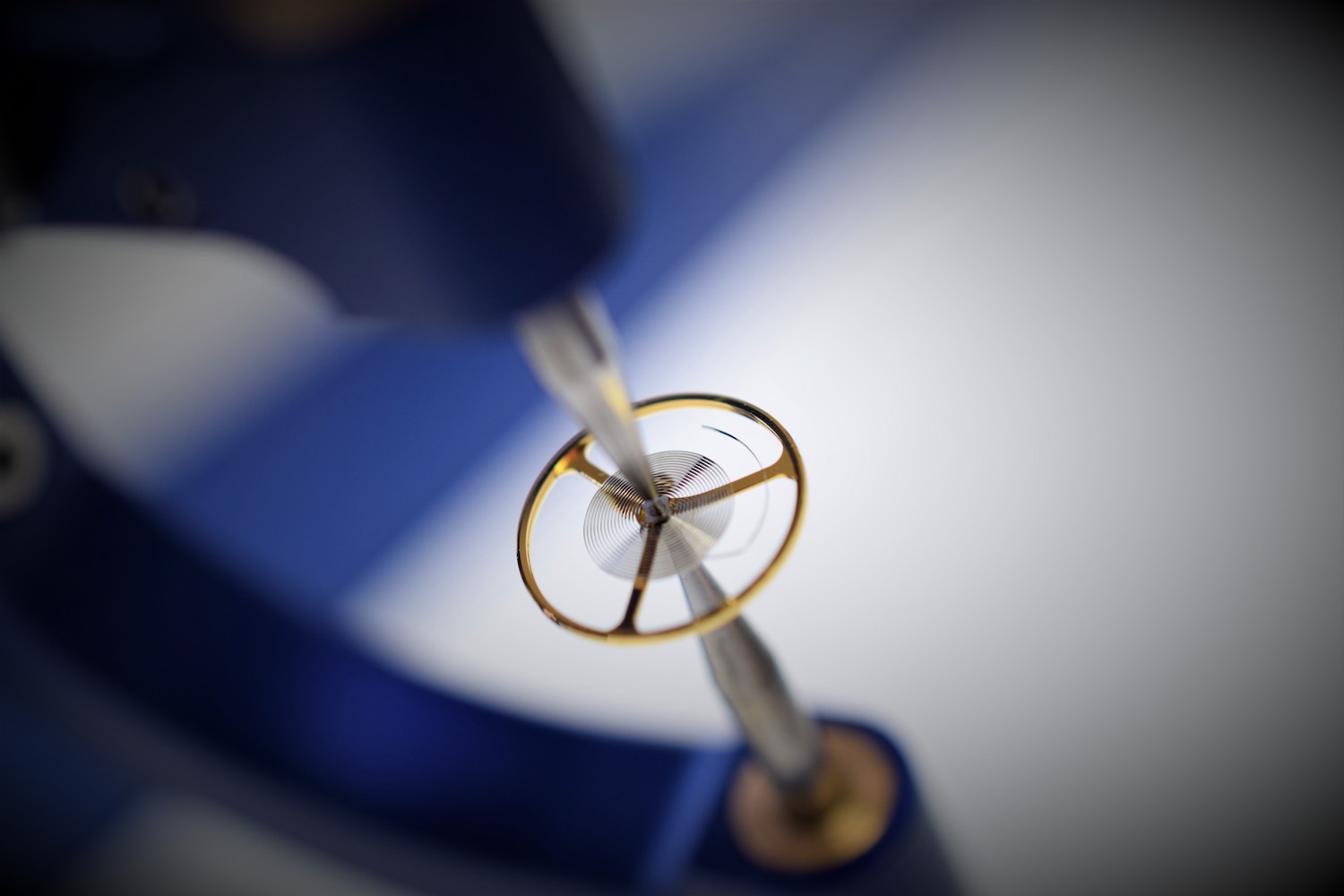

Combining high tech industrial precision and manual work, hairsprings are manufactured through ultra-precise metal lamination techniques to produce a malleable blade. It takes days to transform a metal wire into a thin spring by successive steps. Tolerances are usually under 0.1 micron, as the slightest variations of the spring profile have an impact on the watch performance; a variation of just one micrometer in the thickness of a spring can make a change of 30 minutes on the daily rate. It is then shaped and coiled to obtain a spiral shape.

Rolex Parachrom Hairspring

To be independent from Swatch Group, Rolex was one of the first players to develop a full in-house production capability for hairsprings. Following more than five years of research and development, the first Parachrom hairsprings went into production in the early 2000s. Parachrom is an alloy of niobium and zirconium, with an oxide coating. The name combines “paramagnetic” together with “chrome” (Greek for color). One of the main advantages of the Parachrom hairspring are its non-magnetic properties, plus it is more accurate when subjected to shocks in comparison to ferromagnetic alloys.

Although fully operational much later, Richemont has also built production capability for hairsprings. Like Rolex, it was a matter of gaining independence for the watchmaking powerhouse. The production was initiated in Germany with A. Lange & Söhne and Switzerland with Jaeger-LeCoultre. The integration of Roger Dubuis provided another source. Montblanc-Minerva also manufactures hairsprings although not at industrial scale (mainly for tourbillons and cylindrical hairsprings). Today, Valfleurier (Richemont’s shared industrial center) is the main producer for the group. Not all Richemont movements are fitted with proprietary hairsprings but the expertise and capacity seem sufficient to ensure autonomy.

A. Lange & Söhne Hairspring manufacturing

Atokalpa, part of the watchmaking group owned by the Sandoz Family foundation (together with Parmigiani Fleurier and Vaucher in particular), was among the first to initiate a plan to manufacture hairsprings in the early 2000s. Today, Atokalpa produces over 200,000 assortments per year for Vaucher and third parties, independent watchmakers but also big players such as Tag Heuer. It is today one of the most significant alternatives to Nivarox, having both the industrial capacity and the expertise/flexibility to develop and manufacture complex products in short series (Rolex or Richemont do not sell to third parties).

Concepto, a movement supplier based in La Chaux-de-Fonds, also manufactures hairspring. These are fitted in their own movements although they still also use Nivarox. They also supply to third-party brands. According to CEO Valérien Jaquet, its production would be somewhere in the range of 100,000 units per year.

Precision Engineering AG paramagnetic hairspring with stabilized Breguet overcoil

Precision Engineering AG, an independent subsidiary of H. Moser & Cie. (part of the Meylan Group), is the third significant maker of hairsprings for third parties. Its production is of 55,000 assortments per year. Precision Engineering AG was founded in 2001 as a spin-off of Straumann SA (the company expertise goes as far back as 1930 with the technology then patented by Reinhard Straumann). In 2016, Precision Engineering AG presented a new alloy; PE500. This alloy, comprised of niobium and titanium has a great affinity for oxygen. It is presented as paramagnetic and shock resistant with the advantage of allowing adjustments.

The small circle of companies manufacturing (traditional) hairspring also includes:

- The Festina Group that comprises several watch and jewelry brands but also industrial activities, in particular movement manufacturer Soprod. In addition, the Miguel Rodriguez-led group recently took over Technotime that also manufactures hairsprings, before the company went bankrupt.

- Bovet manufactures assortments although to our knowledge only for its own needs.

- E2O innovation, the sister company of Schwarz Etienne fits the brand’s movements with proprietary hairsprings and is now working for third parties.

Balance and hairspring manufacturing at Schwarz Etienne

For more details about the whole regulating organ of the watch (balance, materials, tourbillon, adjustment) and also the overcoil of the hairspring – including the famous Breguet type – you can check our technical article about regulating organs here.

Silicon

For several years now, silicon has been truly revolutionizing traditional watchmaking. Hard-wearing, light, durable, anti-magnetic, thermally stable and with excellent elastic properties, silicon presents exceptional properties to manufacture hairsprings. However, this technology is available to a limited number of companies only, which is not the case for other silicon components.

The first silicon hairspring was presented by Ulysse Nardin thanks to Sigatec, a joint venture with Mimotec, which specializes in silicon micro-components. The brand has developed a unique expertise in the field. On the other hand, Rolex, Patek Philippe and the Swatch Group collaborated in a joint development with CSEM. They patented the technology which was the reason of a dispute with Sigatec. An agreement between all parties was found (although its terms were not disclosed in 2013).

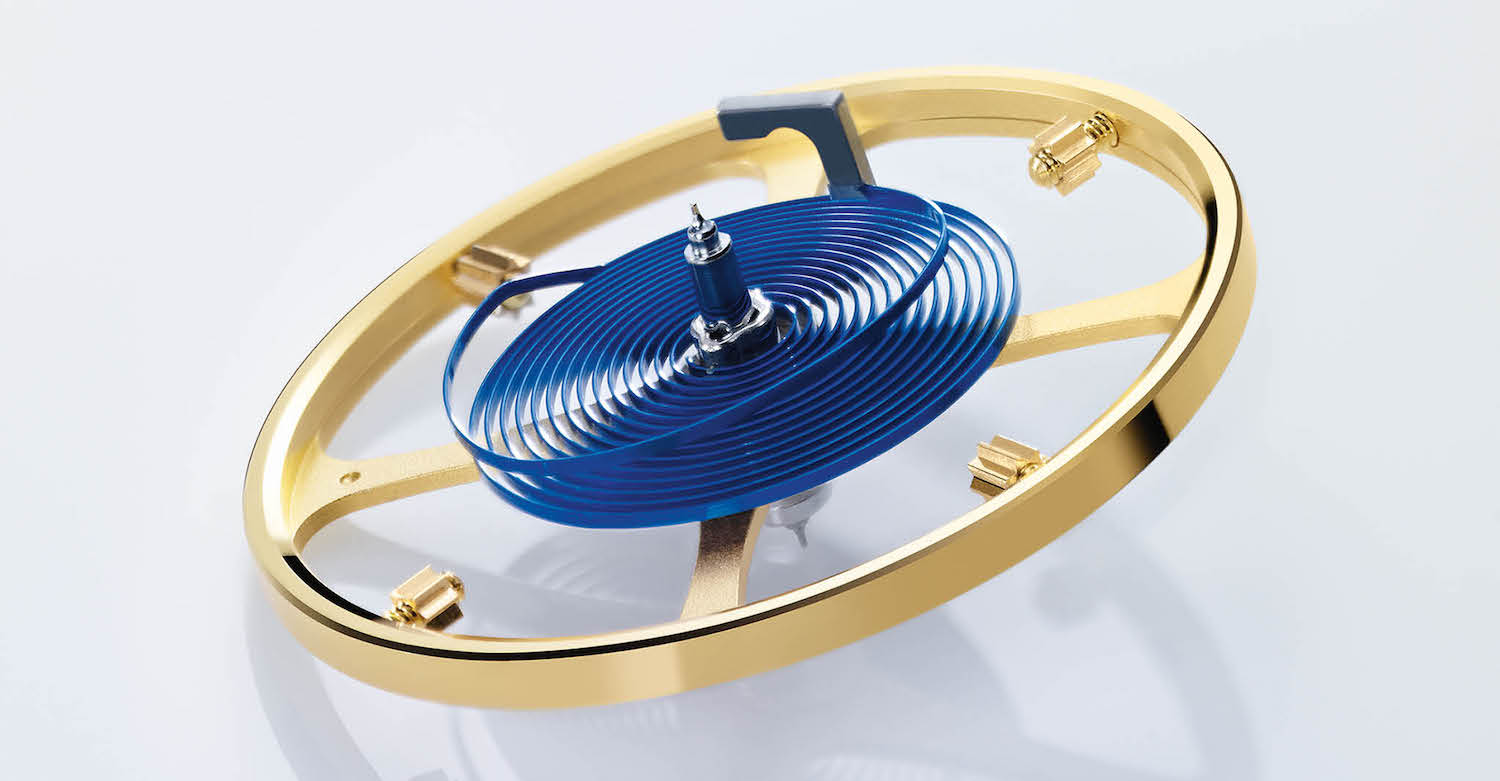

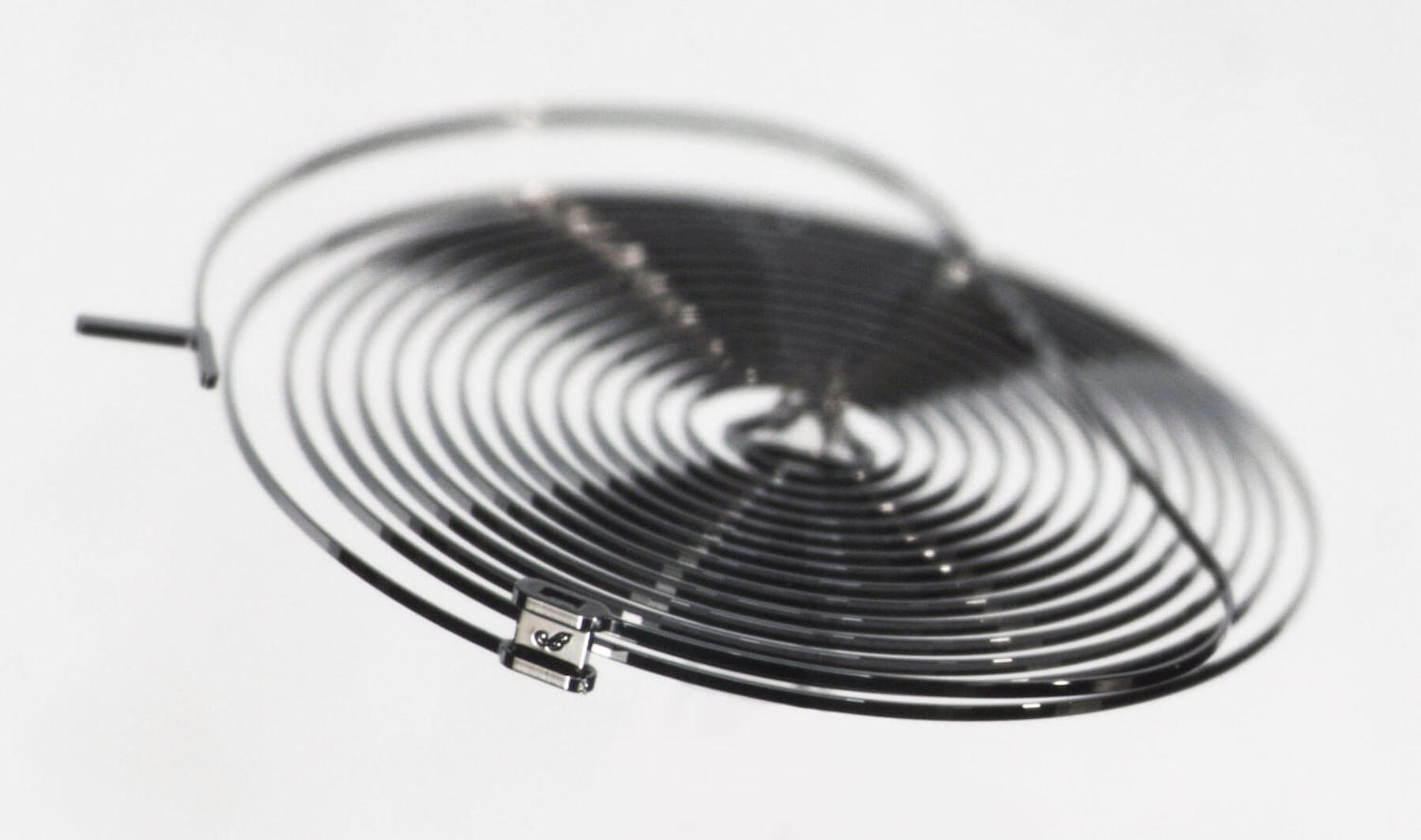

Silicon hairsprings – An interesting and strategic alliance uniting three power houses: Swatch, Rolex and Patek Philippe joining forces through CSEM (Centre Suisse d’Electronique et de Microtechnique) – Above, a Breguet silicon hairspring deriving from this joint research project. Silicon hairspring are in used across different Swatch group brands (Breguet, Omega, etc.). The Patek Philippe advanced research department unveiled their Spiromax© hairspring in 2006. Rolex presented their Syloxi© hairspring in 2014.

However, the CSEM patent will expire in 2021 and the technology will become available. Naturally, several companies (for instance Atokalpa) are therefore investigating and building expertise in the field of silicon hairspring manufacturing. Other high-tech materials have been used to manufacture hairsprings, although the production remains limited as of today. For instance, the Cartier concept watches ID-One and ID-Two are fitted with hairsprings made from Zerodur©, a high-tech glass-ceramic composite.

At Baselworld 2017, Zenith unveiled its Defy 21, with hairsprings made of a carbon-based composite strengthened with carbon nanotubes that has been patented by LVMH, Zenith’s parent company. At LVMH, under the aegis of Jean-Claude Biver, the avenue to master this watch component is that of innovation. The group states that it is investing considerably to develop their production and that the manufacturing facilities are being set up under LVMH Suisse Manufacture.

Unconventional oscillators

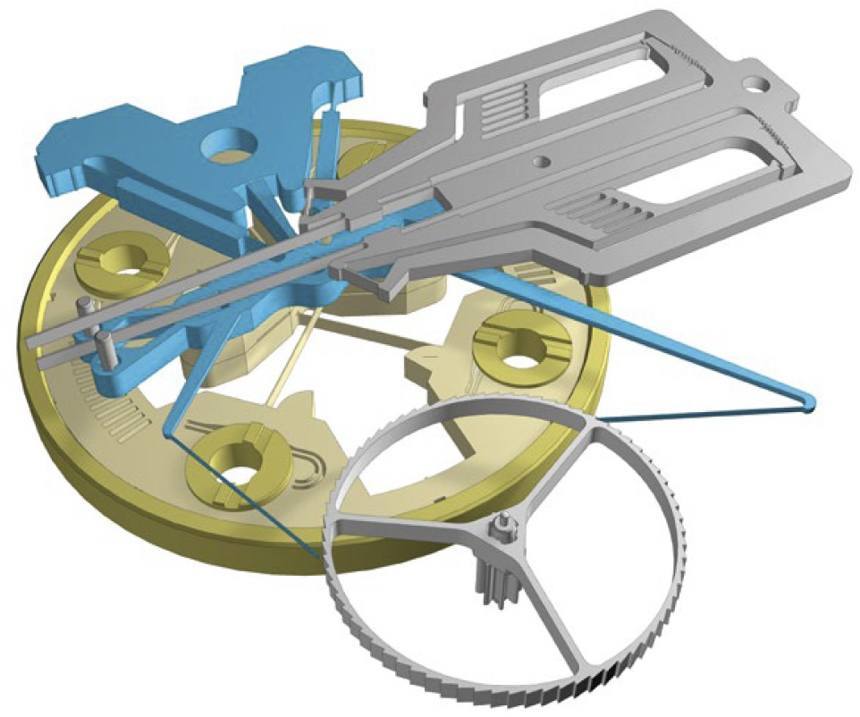

The Genequand escapement and its unconventional oscillator (yellow part)

Beyond the traditional balance wheel and hairspring, “unconventional” oscillators have been presented by watchmakers. In recent years, together with the development of new escapements and the potentialities offered by silicon, these oscillators have been able to reach higher frequencies to enhance precision or to reduce the energy consumption of the movement. Among these, the latest innovations to replace the traditional spiral spring include the TAG Heuer excitatory blade system with linear oscillator fit in the Mikrogirder, acoustic resonators for De Bethune and the innovative balance with flexible blades of the Parmigiani-Genequand escapement… and we expect news from Zenith in this respect very soon so stay tuned!

11 responses

Who does seiko use?

@Pat Mat the article is focusing on the Swiss watch industry. Japan is another source for hairspings, and not only at Seiko.

Hi Xavier,

thanks for the article, helpful to clarify who are the real players in the swiss hairspirng market.

Regards,

slide68

I learned something today, thanks very much for the article.

Xavier , thank you.

What does Omega use in their co-axial movements ?

At the top of the page there was a picture of an Omega hairspring.

Thanks you Peter. The balance pictured at the top of the page is from a coaxial escapement with silicon hairspring (shot in their movement manufacture’s showroom near Saint-Imier). Omega started to use Si14 springs some 10 years ago (2008). Stay tuned more on the coaxial soon!

Great article. I look forward to your writing regarding the coaxial.

It’s a pleasure reading your article about watch insight!!!

Xavier, Merry Christmas!) a great article, as we say in Russian — “without water”) do You know, where top notch brands, like Patek Philippe have their hair springs from? In other words, is it a complete “in house” in the full sence of the word? Thanks

Dear Karen,

Patek does indeed manufacture its hairspring in-house. It isn’t the case for all brands, as the hairspring is a complex piece.

Im sure Vostok still make their own hairsprings in-house.