New Indie Watchmaker Ivan Berets, on the Birth of his Atelier and the Series 1 Oscuro and Levante Watches

With the stylish Series 1 for a debut, the future of Ivan Berets looks bright!

Graduating from his watchmaking studies in Switzerland this year, young indie watchmaker Ivan Berets is set to launch his first watch. Simply called the Series 1, it is based on his graduation project watch, more poetically known as the Montre d’Ecole in French. With Russian roots, Ivan now resides in Italy and has unveiled the Sereis 1 Oscuro and Levante, two takes on a classical time-only watch with a shaped case and intricate details throughout. And best of all, most is done by Ivan Berets himself, and by hand! Time to learn more about this young man and his debut piece.

Trained in classical watchmaking at the Korpela & Hofs Watchmaking Competence Centre in Le Locle, Switzerland, Ivan learned the craft of making a watch by hand, using only manual machines. Today, in his workshop in Desenzano del Garda, Italy, he’s applying this knowledge to introduce a strong presence of independent watchmaking in Italy, a field that he feels has been somewhat overlooked there. His approach is simple: to create timepieces he would genuinely enjoy wearing himself. Ivan’s focus is on proportions and designs that actually fit the wrist, something he believes is often neglected in indie watchmaking.

Robin Nooij, MONOCHROME Watches: You studied watchmaking in Switzerland. What led to this decision? What got you interested in watchmaking?

Ivan Berets: My interest in watches began during my career as a racing driver. As you probably know, motorsports and watchmaking are deeply connected; nearly every racing team is backed by a watch brand, and their branding is everywhere in racing series. When the chance came to explore watchmaking firsthand as a hobby, I quickly discovered it was more than just a passing interest. Within a few months, I decided to pursue it seriously, travelling to Le Locle, Switzerland, for a bench test at Henrik Korpela’s school. I haven’t looked back since.

After your studies, what pushed you to start your own watchmaking atelier?

The idea really grew out of the incredible encouragement and interest I received from both the watchmaking community and collectors while I was working on my school watch, which later became the prototype for the Series 1. As a young watchmaker, I felt it was the right moment to take the leap and see where this path could lead. Of course, starting my own atelier is a significant risk, but that uncertainty is also what makes the journey so exciting.

What’s your goal for the long term? What do you dream of the name Berets to represent in two or three decades?

It’s difficult to define a long-term vision with certainty. My approach has always been to take things one project at a time and allow the process itself to guide me. Rather than setting a rigid destination, I prefer to follow the natural ebb and flow of my watchmaking journey and see where each step leads. What I can say is that first and foremost, I’m focused on refining my craft and building my capabilities.

Your first watch is based on a prototype movement you made during your studies. Can you tell us more about its creation?

The project initially began as a way for me to learn both watch design and CAD modelling. I started about six months into my studies, and over the course of a year, I went through many iterations before arriving at a final design. At that point, I realised we were far enough ahead in the school’s curriculum that I had a couple of months to fully dedicate myself to building a prototype movement.

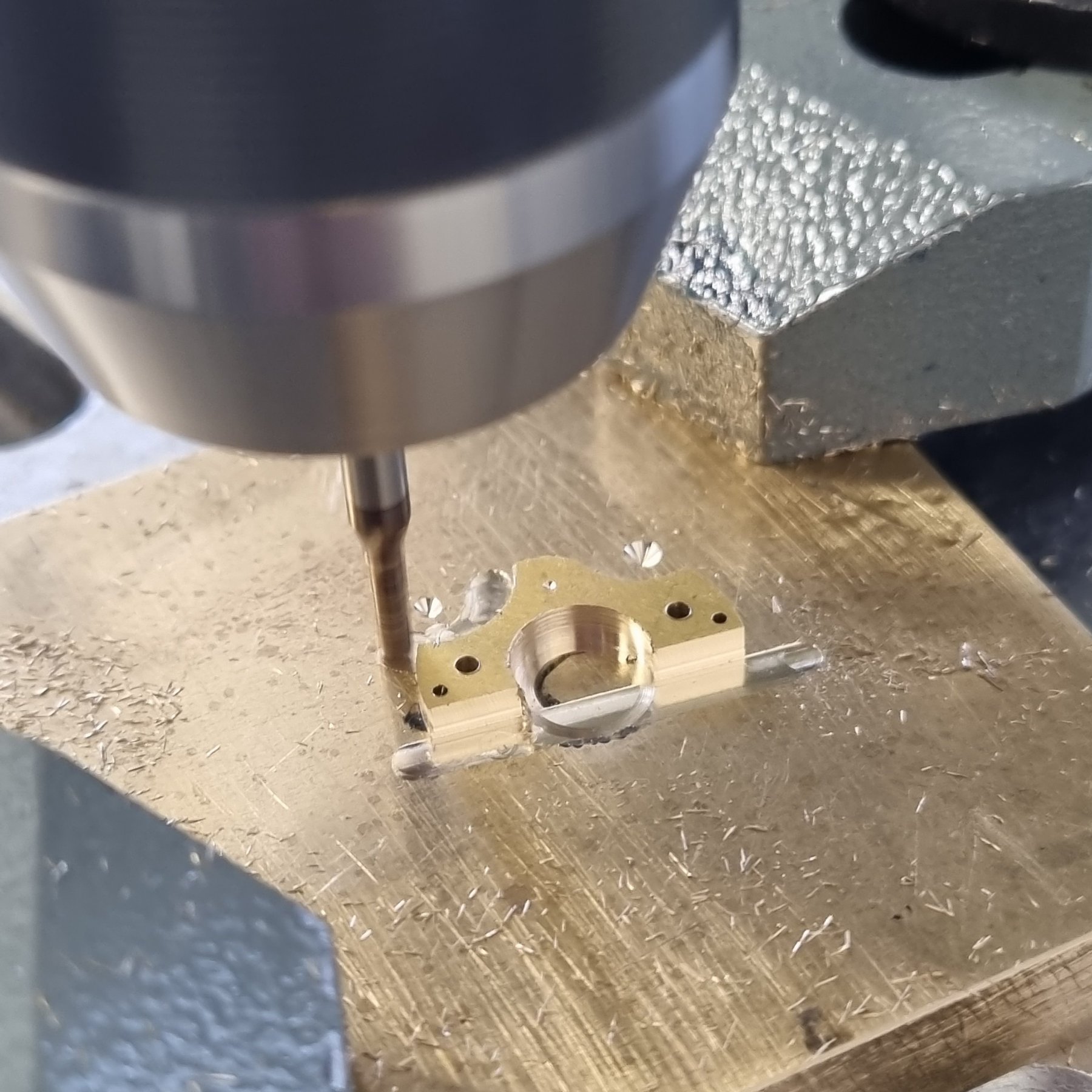

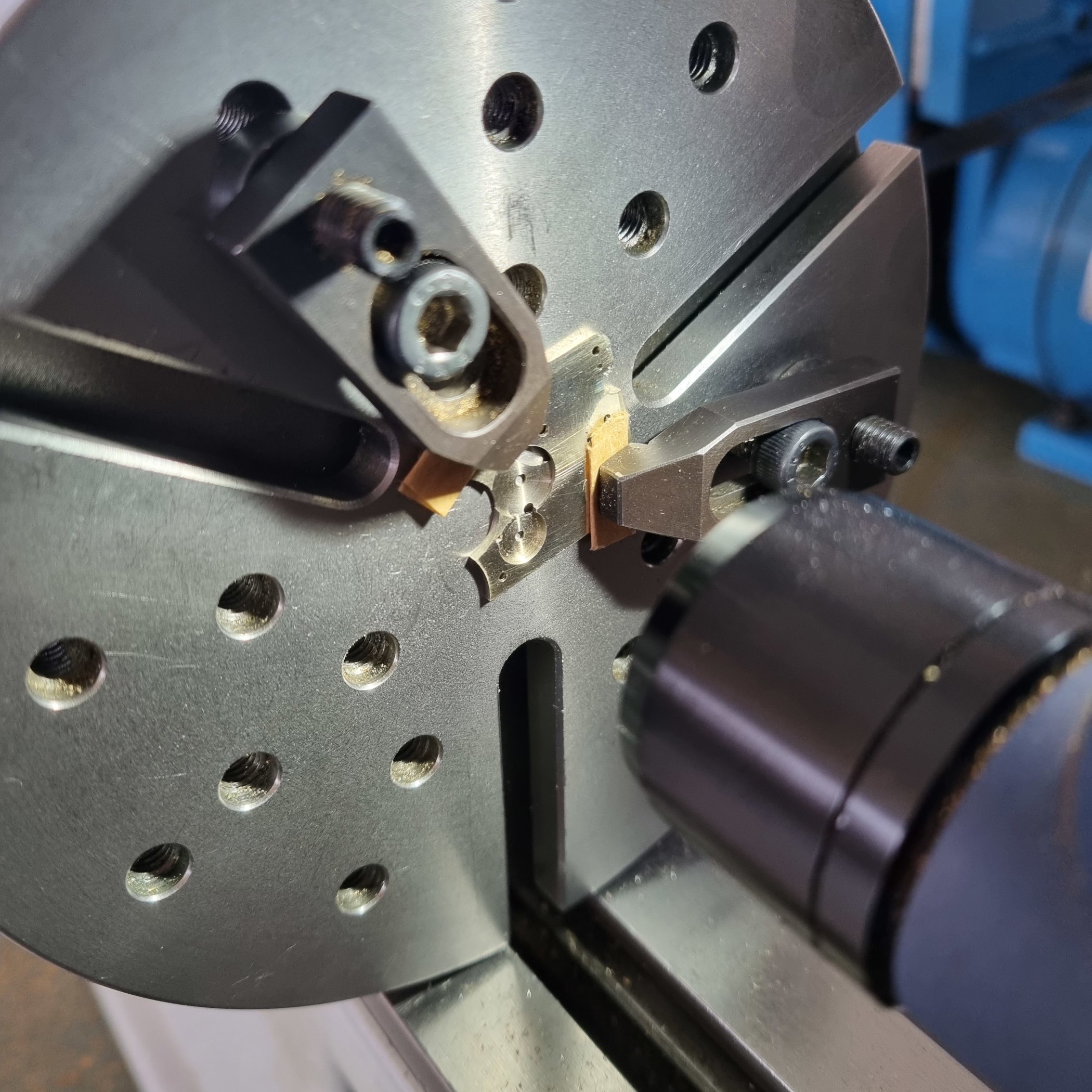

Since KHWCC only has manual machines, it was a real challenge. I had just eight weeks to precisely re-measure the base movement within micron precision, then manually machine all the bridges, the mainplate, and the motion works. On top of that, I had to carry out full movement finishing, something I was attempting for the very first time. It became a great capstone to my studies, as I had to make use of the entire arsenal of equipment taught to me during my training, such as the Hauser 2BA jig borer, the Schaublin 70 and 102 lathes, and the Aciera F1 milling machine.

The Series 1 is largely made by you, but you do use a base movement, correct?

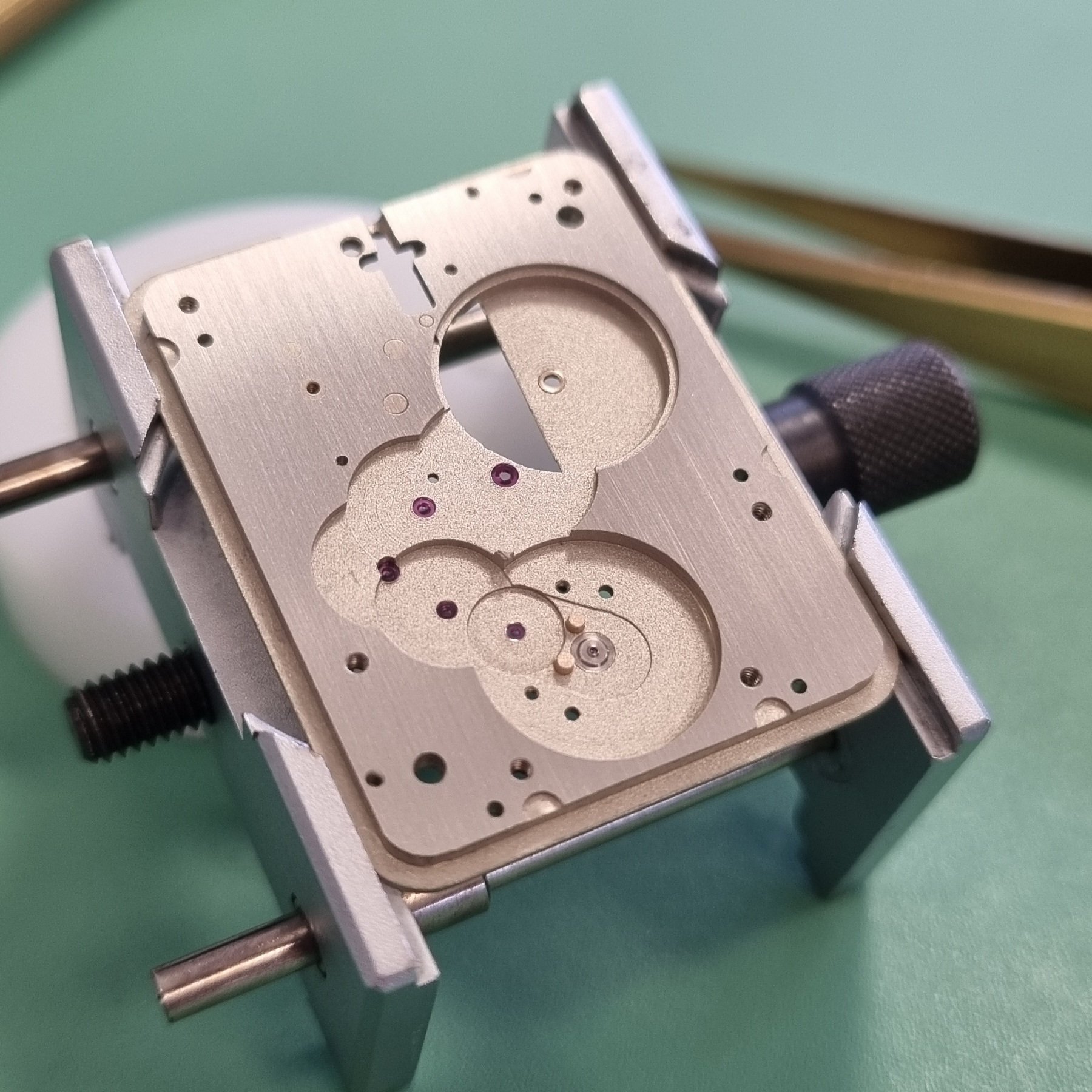

Yes, that’s correct. Most of what you see through the exhibition caseback is made in-house by me; this includes the German Silver three-quarter plate, the bridges, screws, locating pins, and the click system. I also produce the dial, along with some components hidden behind it, such as part of the motion works. The underlying mechanism, however, is derived from the renowned Peseux 7001, from which I retain the gear train, escapement, balance, and the winding and setting system.

And how about the finishing? Do you do that yourself, and was this taught at school?

Yes, I do all of the finishing myself, with the exception of the case. That includes both the finishing of the components I make and the refinishing of the base calibre parts. During school, we explored a wide range of traditional techniques and were encouraged to experiment, which really shaped my approach. One area I focused on extensively was developing the distinctive finishing for the ratchet wheel, which takes centre stage in the Series 1. Perfecting that look was a rewarding process of trial, error, and refinement.

You’re launching with the Series 1 Oscuro and Series 1 Levante. What’s the story behind those names and the differences?

The names of the Series 1 pieces carry both aesthetic and personal meaning. Oscuro in Italian can mean “dark” or “obscure”, which is reflected in its black rhodium dial and bridges. It also speaks to my position as a new independent watchmaker, arriving quietly on the scene with much still to prove.

Levante, on the other hand, conveys the opposite spirit. Meaning “rising” or “east”, it evokes the sunrise, which is expressed through the warm tones of rose gold. For me, it represents a symbolic rising, a more optimistic and radiant counterpart to the Oscuro.

The two also diverge in their finishing. The Oscuro features purple screws, broad Geneva stripes across the three-quarter plate, and a frosted mainplate, giving it a bold yet shadowed character. The Levante instead showcases a traditional hand-scraped grattage finish on the mainplate and a bright frosted three-quarter plate, finishes that catch and play with the light in a way that mirrors its name.

You’re about ready to start accepting orders, correct?

Yes, I’m now accepting orders for the first batch of Series 1 watches, which are scheduled to ship around mid-2026. For now, the Oscuro and Levante are limited to 20 pieces per configuration.

What’s in store for the future of Berets Watchmaking? Any ideas for the next project you can already share?

I can’t give away too much just yet, but I can share that I’m currently developing a fully in-house calibre.

How can people get in touch with you to learn more or reserve one of your watches?

You can find more about me and the Series 1 on my website or through my Instagram. If you have any questions or are interested in reserving a piece, feel free to reach out via email at [email protected] or simply send me a message on Instagram.

For more information, please visit BeretsWatches.com.