Michiel Holthinrichs on 5 years of Independent 3D-Printed Watchmaking

One of the rising stars in Dutch mechanical watchmaking shares his current affairs

In the past five years, we’ve been pretty much in continuous touch with young Dutch watchmaker Michiel Holthinrichs. Through his eponymous brand, Holthinrichs Watches, he showcases his passion for design, architecture and craftsmanship. And to make it stand out from the masses, he uses 3D laser-printing technology not just as a gimmick, but as a tool to create unique shapes that radiate his vision in watchmaking. Celebrating five years since the start, we’ve recently been witness to the ultimate expression of Michiel’s creativity so far, the Holthinrichs Raw Bronze. All the more reason to sit down and catch up with Michiel, as a lot has happened in those five years.

Robin Nooij, MONOCHROME – Michiel, thank you for taking the time to talk to us. You’re celebrating your fifth year as an independent watchmaker, so congratulations on that! How do you reflect on those five years?

Michiel Holthinrichs, founder of Holthinrichs Watches – As a rollercoaster! One year after I graduated from Architecture and launched my brand, I needed to move out of my student’s apartment. I decided to rent an atelier space to house my watchmaking tools and to be able to invite clients. It was a big risk, I didn’t even have the money to rent a room besides that, so I just dropped my mattress in the back of the atelier. I really went all in. I have been taught by my parents, if you really have a passion for something, just do anything to follow your dream.

The years thereafter were quite hectic, often I had the fear of bankruptcy, and often I was saved by the bell. Every penny I had I invested in development, better tools and education. I earned some extra cash by repairing vintage watches and working freelance in architecture for a few months. I realized I needed to hold on, invest probably 15 years of my life living on the edge, and remain focused.

Now, 5 years later I have a beautiful historic space in the city centre of Delft and I am supported by a team of very passionate specialists; watchmakers, product developers, industrial designers and engineers. Together we are looking towards a creative future. I am very thankful for all the people that gave me the trust to work with me!

There have been some big changes regarding Holthinrichs Watches. Can you talk us through some of them?

Well, one of the big things for me was to move the atelier to a bigger, more transparent space in the city centre a year ago. I simply needed the extra space, but the choice for a city centre corner location with four big window panes was very conscious. People can walk by and see pretty much all the steps in the process of the artisanal creation of a watch. I like to express my transparent approach to watchmaking and to make people enthusiastic about all the different crafts and skills involved.

However, the biggest step for me is not to be working alone – like a hermit – anymore. A few years ago in an Instagram Q&A, I mentioned my dream to build a small, dedicated and creative team to be able to explore the boundaries of watchmaking and create horological art. After having a very turbulent but successful 2020 the only way forward was to surround me with fantastic people to help me on the journey of building this brand. You can imagine how excited and proud I am of every individual in the team.

For me personally, it is also quite a challenge. I need to train people, but also I also need to learn to let things go. I used to process every step in the making of a timepiece myself, and now I have to admit that somebody else is actually better at certain tasks than I am.

My biggest love and strength lies in the design side of the job, and this is where I will be focussing on more and more. And together as a team, we can reflect on designs, generate ideas and elevate the concepts we are creating. There is a very progressive vibe and the ambitions are very high, addressing all aspects in the creation of Haute Horlogerie. From making dials to movement design and finishing, but most importantly; the development of our architectural design language and material expression.

You are a pioneer when it comes to 3D printing in watchmaking, and you’ve not only done steel but also gold and platinum. How has that technology evolved for you since you’ve started?

Oh boy! Where to start! 3D metal printing is in constant development. I am always following the latest developments to get the best print resolution, the nicest details, and the most design freedom. I have shifted from a technology called Direct Selective Laser Melting towards Metal Binder Jetting because of the fine details and the lack of the need for support structures during the printing.

A technical story, but to cut it short, there are fewer technical risks involved in the process and much more freedom for design. Much is possible, but mind you, I will not go for anything less than a very stylish appeal, because I love a smart design. So in my work, you will have to look into the joints between elements, the finesse of the curves, thickness (or thinness) of elements and proportions, into the architectural details of the design. We are developing some cool stuff currently!

You’re doing more and more bespoke work. Has that always been a focus, or did it simply happen naturally?

As an independent watchmaker, the way to operate is to work directly with your client. This is most often an individual, but it could well be a group of people or a retailer. The best thing is that you always get the chance to create original things, and you maintain control over the quality of the whole. With the expanding team, I firmly envision this will always be our modus operandi.

Currently, we are working hard to expand the Ornament 1 and RAW Ornament lines with new models and to build clarity in our core offering. We are also developing new lines, but bespoke work will always stay important, but it will likely shift towards a more specialist side.

Through all your years of hard work as an up and coming watchmaker, what has been the biggest challenge to overcome?

Time management (pun intended). I always want to do everything myself, and I am full of ideas, dreams and visions, but I constantly overestimate my time. I also have a hard time letting go of some of the watchmaking aspects. I am clearly a more creative person rather than a rational technician. I believe this creative mind is my strength, but it can also lead to personal disappointments. I am lucky to work with fantastic, understanding and patient people, but I am very well aware that I need to work on this. Within the team, there are clearly more qualified people to help me with this.

We’ve recently covered a bronze model with a very special dial and movement. Can you explain how that came to fruition?

Our first model is the Ornament 1, which is a very classic Art Deco-inspired design. Fully polished cases and clear proportions make the watch look elegant and timeless. I regard this model to be the all-time classic model of the brand. As a counterpart, I introduced the RAW Ornament, which is inspired by early modernist and brutalist architecture. It has the same dimensions as Ornament 1, but the textures on the watch are very bold and rough, some directly derived from the 3D printing process. It only has selective polished details to emphasise the boldness of the overall design.

For this design direction, I am heavily inspired by Le Corbusier’s concept of “Beton Brut”, or “Raw Concrete”, which points out a philosophy that a building should showcase material honesty and express the intrinsic beauty of both the materials used in construction, as well as the textures derived from the process of working with these materials. In my watchmaking venture, I am a strong advocate for using pure materials, interesting materialistic textures and colour expressions that are naturally derived from these materials. I believe this is the most durable way of making a watch and providing insights in the processes. In my work I have adopted Le Corbusier’s term into “Horlogerie Brut”.

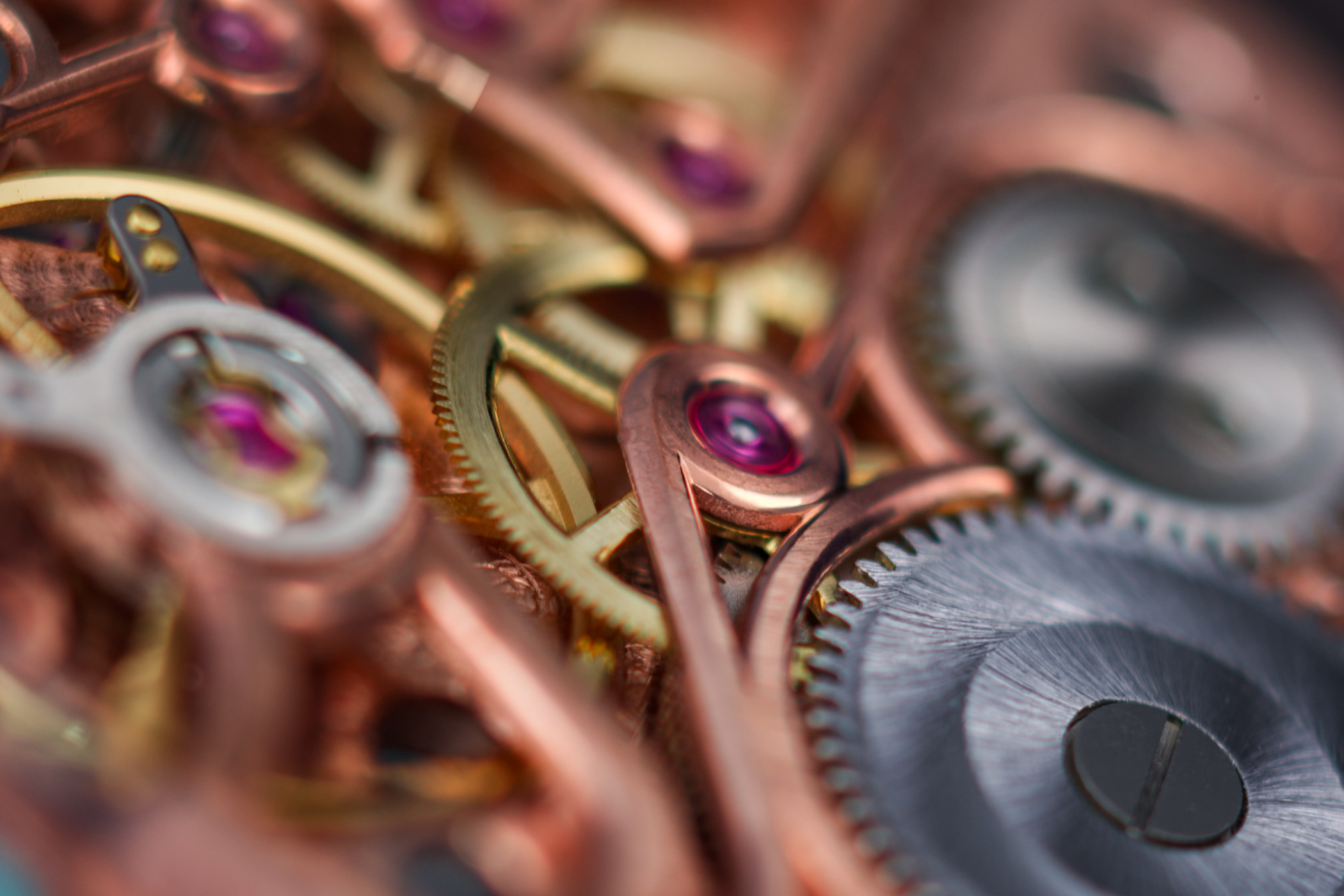

The RAW Bronze model pushes this concept to new heights for me, by introducing patina for extreme material textures and the physical expression of the notion of time. The case is made out of solid bronze, the dial is made out of pure copper with applied patina to get a unique colour. I fully embrace the fact that every part of the watch will ‘live’ and change continuously. There is no perfect version. Even the movement, which I regard as the hidden treasure in this watch and which has seen about 100 hours of manual finishing is copper plated to embrace the time having an impact on it. To me, it is the ultimate form of “Horlogerie Brut”!

(It is important to note the movement develops a patina over time, but this will NOT impact its accuracy)

Looking towards the future, what are the biggest challenges for you? Any future projects you can already shed some light on for us?

Until now we have been working with lovely slender NOS Peseux 7001 movements. We have been reworking and refinishing the movements to match our design language and to focus heavily on traditional finishing techniques. We have actually improved the performance of the movements significantly and I dare to say we know it inside out.

In the next models we will showcase our love for, and knowledge of this movement by pushing the level of finishing and de-/reconstruction, including many newly developed parts. An integrated design through all aspects of the watch, and featuring a completely new case design that touches the boundaries of 3D metal printing. I can’t say anything more yet, but in the near future, we will present a very expressive model. It is the logical next step before starting the use and development of new movements.

You’re also involved in Delft Watch Works with your friend Twan Briels. How is it working on two brands at the same time like this?

Twan and I are friends since we met each other in the waiting line for our first day at the faculty of architecture. Although he shifted towards structural engineering we found each other in the love for watches. Inspired by our own student’s life we came to the idea to design a watch that is more wallet-friendly, but within the boundaries of its production methods just as original and stylish as possible. And with some DNA and features derived from Holthinrichs Watches.

Although Twan is very humble, he is actually a rather talented businessman and currently leading the operations, while my attention is mostly focussed on Holthinrichs Watches and its rapid development.

Any final thoughts to share with our readers?

Well, If I think about the past five years, and the years of designing and prototyping before that, I can only be very grateful for what happened, whoever helped me and put faith in me. I would specifically like to thank the great team that is helping me now. We are all very close and on the same track, which gives such good energy!

Ten years ago I couldn’t have expected to be in this position now. I was still convinced I was to become an architect, although I had my doubts already about architectural practice. I think by now I actually organize my company somewhat like an architectural firm. Fun fact to reflect on, but in the very first article you wrote about my work you mentioned the words “Watchmaking Architecture”. I still think these words describe best the way we approach our creative process.

For more information, please visit HolthinrichsWatches.com

1 response

The natural bronze and copper is stunning. Although the dial is already a masterpiece (with perhaps the best use of breguet numerals ever), I would love to see a moonphase perfectly integrated into the aesthetic.