Inside Sellita, The Giant Supplier of Mechanical Movements

A look at where many mechanical watches start their lives…

The words in-house and manufacture have been used and abused by the watchmaking industry for many years. Yet, the reality is somewhat different. This isn’t a bad thing, actually, because vertical integration is not an end in itself. And it has never been; watchmaking was born as a cottage industry. When it comes to movements, many brands source their engines (and many parts, for that matter) from third parties. Producing a movement is a complex endeavour; it requires thorough expertise and a critical size to manufacture reliable calibres while controlling costs. In this respect, you have probably heard about Sellita movements. These are some of the most commonly used calibres in luxury timepieces. Created in 1950, the company has become one of the industry’s best-known and most prolific mechanical movement suppliers, with its products beating in the cases of millions of watches.

The story of Sellita goes as far back as 1950 when Sellita Watch Co. SA was founded in La Chaux-de-Fonds by Pierre Grandjean. Sellita would become one of many ébauches (unassembled base movements and their parts) assemblers for the Swiss watch industry. Back then, most watch brands relied on third-party movements assembled by industrial companies; in-house movements were rare, to say the least. Sellita was acquired in 2003 by Miguel García, the current CEO and owner, who started his career as a production employee in 1987 before becoming its director in 1995.

Under his management, Sellita has become a prominent supplier for the industry, if not one of the most crucial companies on the watchmaking scene. With 850 employees and a production of 1,500,000 movements in 2022, Sellita is the largest movement supplier for third-party brands in the watch industry – besides ETA, which now focuses on Swatch Group brands. But we’ll come back to this later.

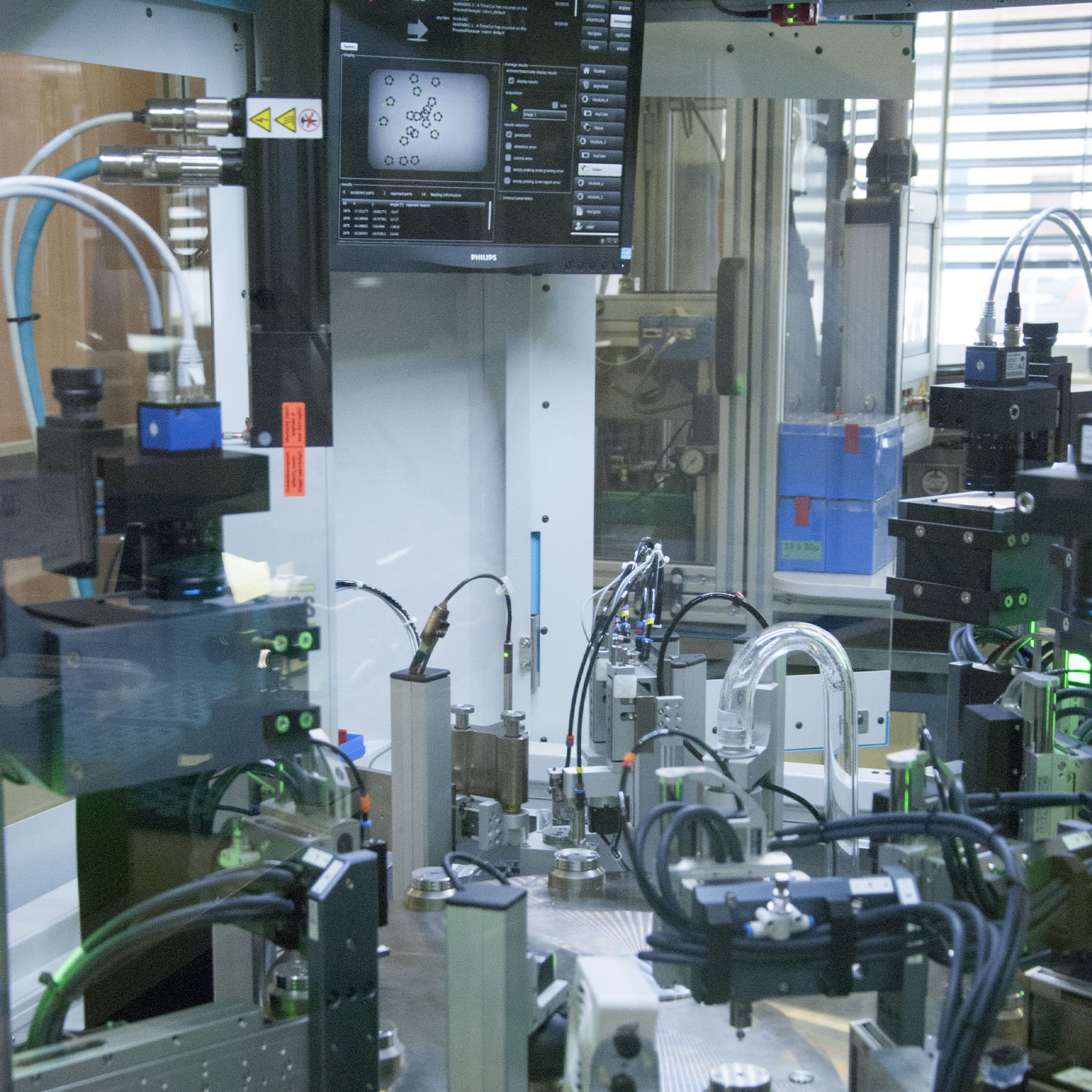

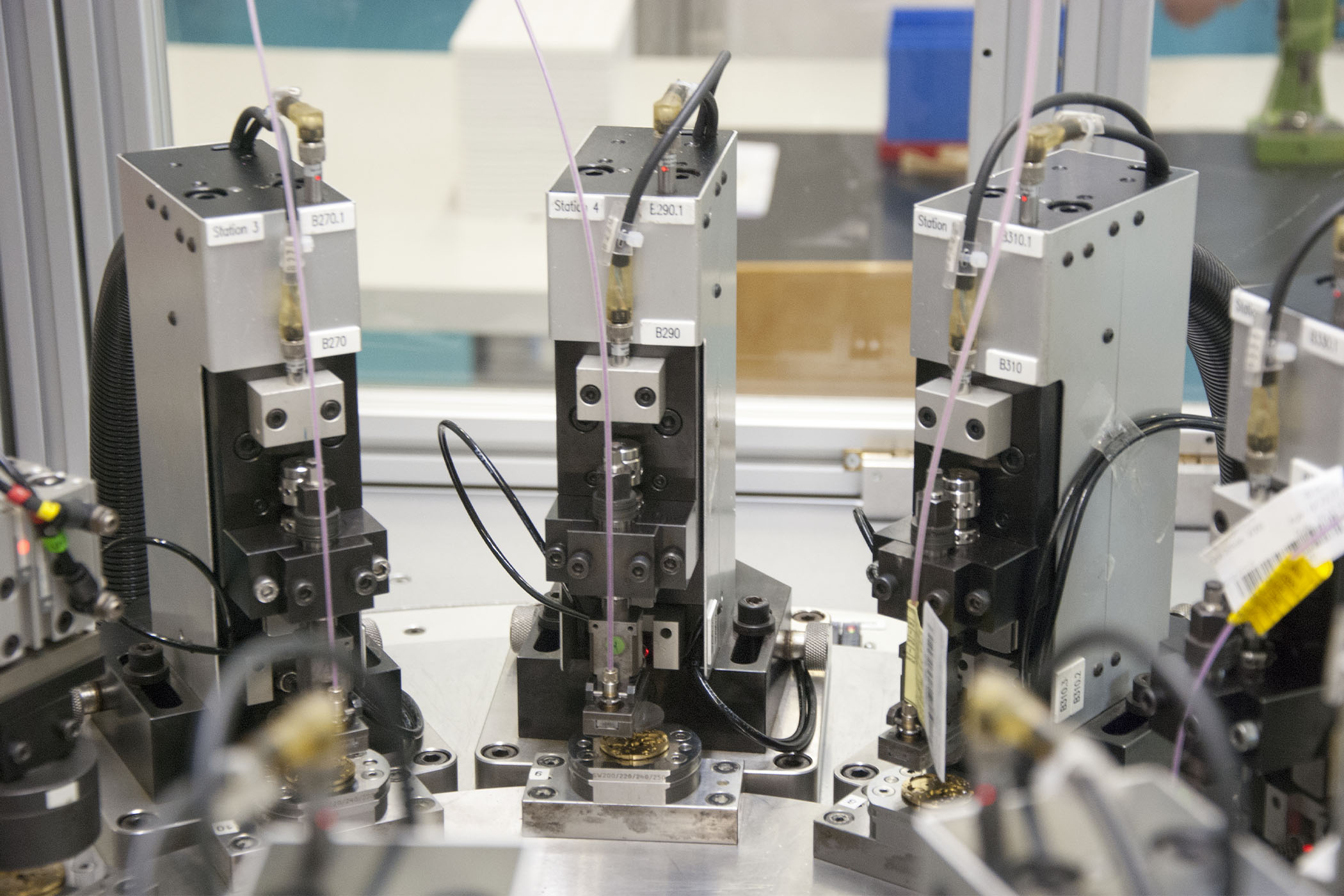

Having reached a critical size, Sellita has become a fully fledged movement manufacturer and a true production powerhouse. The result of a vertical integration strategy, it has its own movement blanks factory (Gurofa GmbH, based in Glashütte, Germany), its own electroplating and decoration business (Technicor, based in Les Breleux, Switzerland) and a bar-turning company (Helios, based in Bévilard, Switzerland). The company is now headquartered in Le Crêt-du-Locle, in ultra-modern facilities. If it has established long-term relationships with a large network of suppliers, the level of vertical integration is impressive. Its expertise encompasses the production of regulating organs for mechanical movements (hairsprings, balance wheels and escapements) and ball bearings. There are two in-house laboratories; one is dedicated to analysing materials. The company’s expertise even extends to the design and manufacturing of its own machines.

The early 2000s have been a turning point for Sellita… At the time, very few watch brands were manufacturing movements. Swatch Group, buoyed by its main movement supplier ETA (but also Frédéric Piguet, Nouvelle Lemania and, most importantly, Nivarox, a company manufacturing regulating organs for mechanical movements), had a powerful position and a genuine competitive advantage within the Swiss watch industry. ETA became a single company in 1985, as several ébauches factories were grouped under the name Ebauches SA. This plurality allowed ETA to offer a wide range of reliable, accurate movements at affordable prices.

With the Swiss watch industry flying high, ensuring a steady supply was crucial. In 2002, Nicolas G. Hayek announced that ETA would stop delivering ébauches, warning the competition that he wanted Swatch Group to focus on its own brands. A settlement with the Swiss Competition Commission, the COMCO, ruled a step-by-step reduction of deliveries. This, in turn, led other companies to speed up the integration of movement production, with differing success rates, or seek other off-the-shelf movements. Manufactured by companies such as Sellita, clones of ETA movements, whose designs were in the public domain, were perfect options (it was easy for brands to switch from ETA to a clone without changing much to the rest of the watch) and, as such gained popularity. They allowed brands to switch easily and economically from one supplier to another and ensure continuity.

Sellita has become the main alternative to ETA movements. After assembling ETA movements, Sellita developed its own movements, so-called clone calibres, such as the Sellita SW200 (equivalent to the ETA 2824), the Sellita SW300 (equivalent to the ETA 2892), the SW500 (equivalent to the ETA Valjoux 7750 chronograph) or the SW100 (equivalent to the ETA 2671). Of course, this was easier said than done. Developing a range of reliable movements required substantial effort and investment over many years.

Today, Sellita movements are not just straightforward clones because, over time, the base movements have been upgraded. For instance, the power reserve of the SW300 or SW500 has been beefed-up compared to the original calibres. A new version of the SW200, which maintains the same dimensions (to allow brands to switch without changing the casing dimensions) but will be a brand-new movement, will be presented within two years. Movements such as the SW1000 (20mm x 3.90mm) are developed without correspondence to standard dimensions.

Below, from left to right and top to bottom; SW100, SW200, SW300 and SW500

Besides this core business – supplying affordable entry-range mechanical movements – Sellita has now developed a large collection of customised movements and small-to-medium complications: skeleton movements, regulators, chronographs, GMTs, moon phases, or power reserve indications. And with its sister company Manufacture AMT SA, based in Granges, Switzerland, it also offers higher-end movements. The idea is to compete with manufacturers such as Kenissi or La Joux-Perret, for instance. In particular, Manufacture AMT develops and manufactures higher-grade proprietary movements for third-party brands that want their own design and specifications rather than ubiquitous off-the-shelf movements used by multiple brands. One of Manufacture AMT’s projects that has been publicly disclosed is the TAG Heuer TH31-00 with its 4Hz frequency, 80-hour power reserve, 30 jewels and double ball bearing. A so-called proprietary movement with COSC certification, it has found its place in the case of the recently presented TAG Heuer Aquaracer 200 in solid gold. And there will surely be more to come.

For more information or to browse through Sellita’s movement portfolio, please visit www.sellita.com.

3 responses

the most important thing is that they did not indicate at least approximately the base prices for the mechanisms. in the swiss market only through marketing I think the prices for watches with the same mechanism are from selite. the same from ETA,, Ronda miyota can differ dozens of times, while they will be made of the same materials, inserted into cases from the same manufacturer, covered with the same lume, and having the same cheap sapphire glass. therefore, it is still interesting for the consumer to know how much an automatic caliber costs. as for example it is easy enough to know how much an apartment costs which has become so cheap that many craftsmen simply flip / change the mechanism without doing any repairs. maximum cost two drops of superglue under the dial

How does the higher end movements of Sellita’s Manufacturer AMT compare and contrast with La Joux-Perrier’s movements, including the chronograph with column wheel movement from each brand?

@J. Quincy Magoo it is always difficult to compare movements.The AMT 5000/5100 is a SW500 base that has been extensively reworked from both aesthetic and technical perspectives. Unlike the SW500 it features a column-wheel, something that is available with LJP for some 7750 architecture chronographs. It has a flyback fonction and bi-directional winding which, to my knowledge, is not the case with the SW500 or LJP calibers. The automatic winding module is new with planetary reverser gears…