How Does Grand Seiko Make the Dial of the White Birch SLGH005? A Step-By-Step Look

A step-by-step look at the manufacturing process of one of the most impressive dials on the market.

Grand Seiko, the high-end branch of the Seiko Watch Corporation, is known for its impressive attention to detail. Whether it’s the polishing of the flat surfaces of the case using the Zaratsu technique, or the stunning execution of the hands, there are dozens of small details to contemplate on a GS watch. The dials featuring intricate patterns are also worth a closer look. To illustrate this, there’s probably no better watch than the White Birch SLGH005, a model that genuinely stunned us when it was released last year. The striking silver-coloured dial, with its deep pattern and alternating peaks and valleys, has generated many positive reactions. And rightfully so. Today, thanks to the GS9 Club, we invite you to a step-by-step tour to discover precisely how Grand Seiko manufactures the dial of the White Birch SLGH005.

We often talk about movement making when exploring the beauty of watchmaking. Beauty can be found in the development of a complication, the construction of the smallest parts, the decoration of the elements, and the way it is manufactured and finished. But a watch is more than a movement. In addition to the mechanical part, there’s what the French side of the industry calls the habillage, all the external parts that actually make a watch… a watch. Case, bracelet, hands and, of course, the dial.

Dial making is one of the most fascinating areas of the industry, requiring impressive skills and great attention to detail. There are dozens of techniques in the world of dial making, often traditional rtechniques requiring manual labour. This is one of the reasons why many brands outsource this process to specialised companies, named cadraniers or dial makers. Not many watch brands have their in-house cadraniers, but one of them is Grand Seiko. And seeing the latest releases of the Japanese brand, such as the SLGA007 Lake Suwa, the SBGW289 Cherry Blossom or the SBGA413 Shunbun, you can see that Grand Seiko has an impressive level of expertise in this field too. Grand Seiko isn’t just about technically advanced movements or superbly finished cases; dials are also of great importance in the design and quality of these watches.

This article of the GS9 Club, a membership organisation for owners of Grand Seiko watches that was once reserved for Japan but is now accessible to American and European collectors, takes us on a tour inside the manufacturing process of one of the most striking, detail-oriented and fascinating dials ever released by the brand – and probably one of the most notable dials currently on the market, that of the Grand Seiko Hi-Beat SLGH005 White Birch.

When it was released in early 2021, this watch generated positive reactions primarily due to the striking design of its dial. Surely, there was much more to explore, such as the new shape of the Evolution 9 collection or the innovative 9SA5 movement, but the dial was undoubtedly the attraction here.

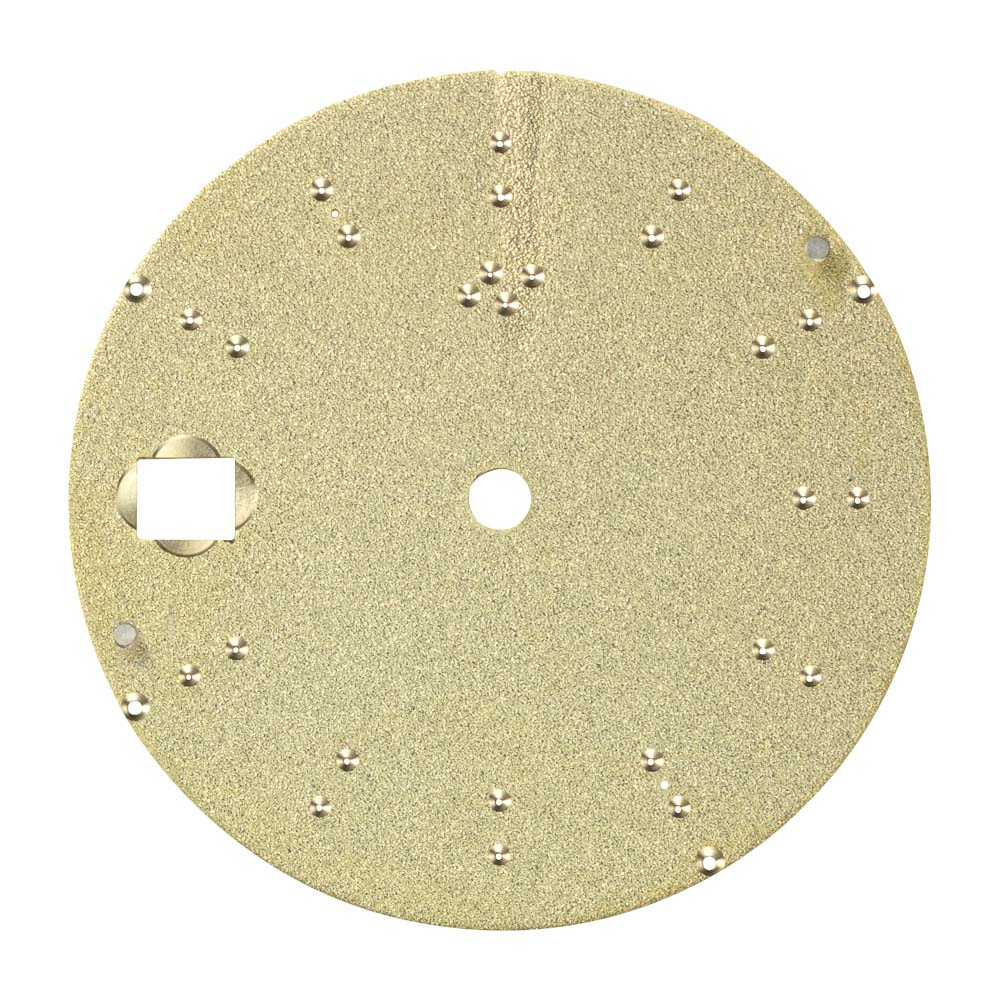

The main aspect of this dial is its intricate, deep texture. And achieving this requires skill and patience. It’s not just about stamping a pattern on the dial. Due to the complex texture and the depths of the pattern, a single stamping wasn’t sufficient to achieve the desired effect. As such, the dial base, cut from a piece of brass must be stamped more than once to achieve the desired effect and avoid cracks under heavy pressure on the thin (0.5mm) brass sheet. The GS9 Club article explains that “the pattern is applied via seven low-impact stampings, or press patterning passes to achieve the necessary result“.

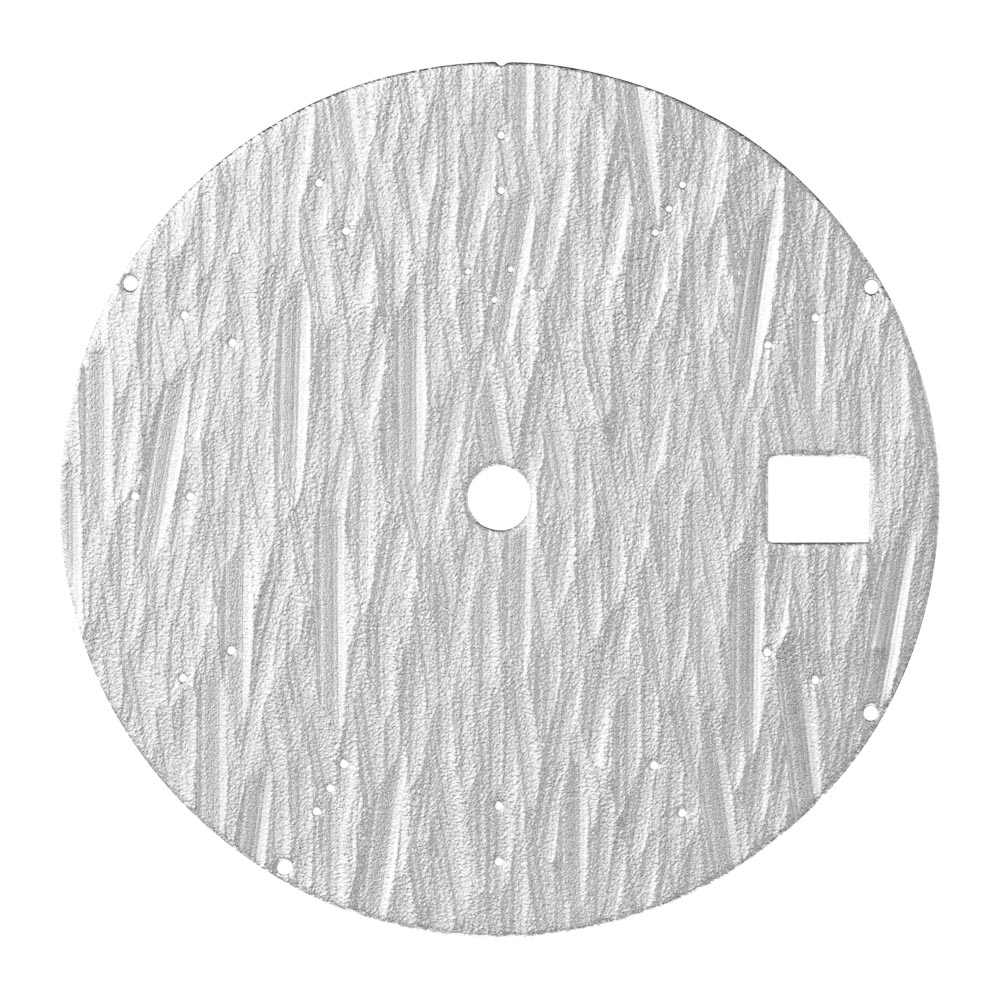

Once the pattern is stamped and unnecessary material has been removed from the dial, openings for the hands and window are cut and holes used for mounting the indexes to the dial are punched through. This is normally a rather simple step, but with such a complex pattern, great care is required. The dial is then inspected, cleaned and ready for surface finishing in the form of metal brushing, silver plating, undercoating, and wrap coating.

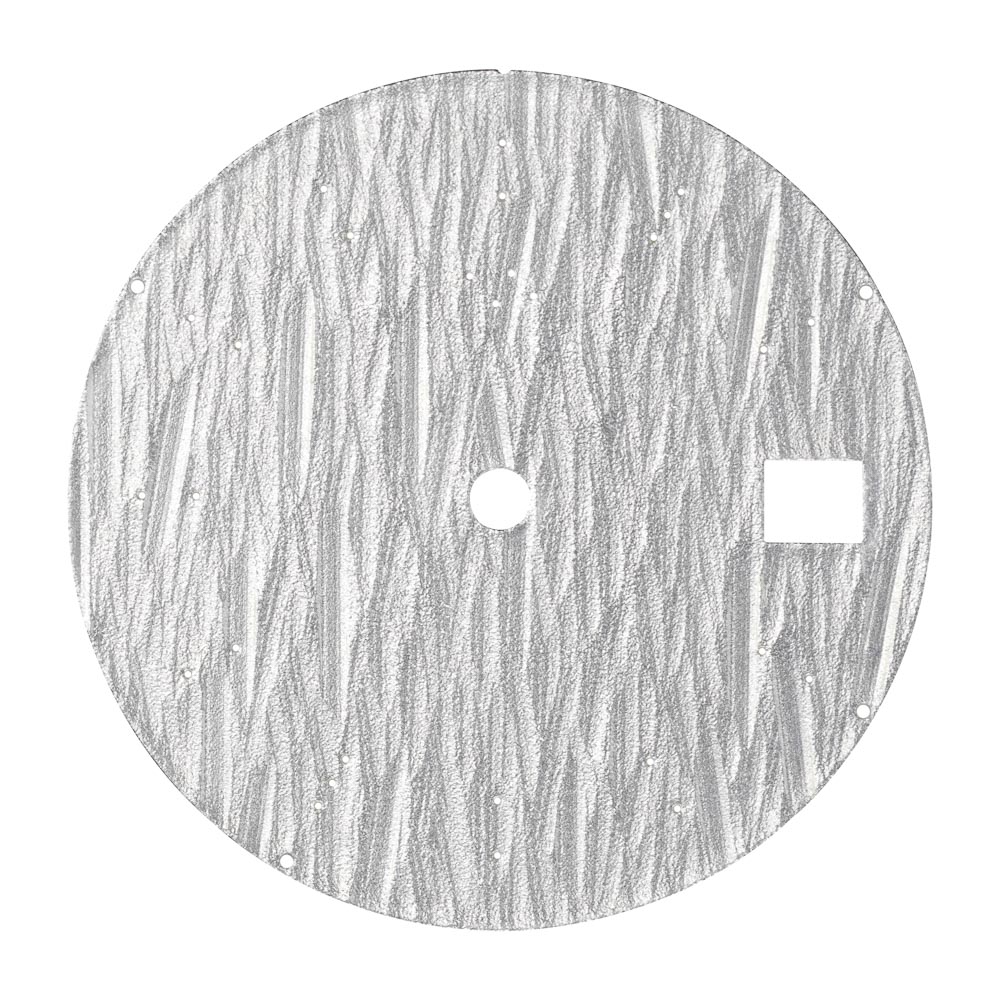

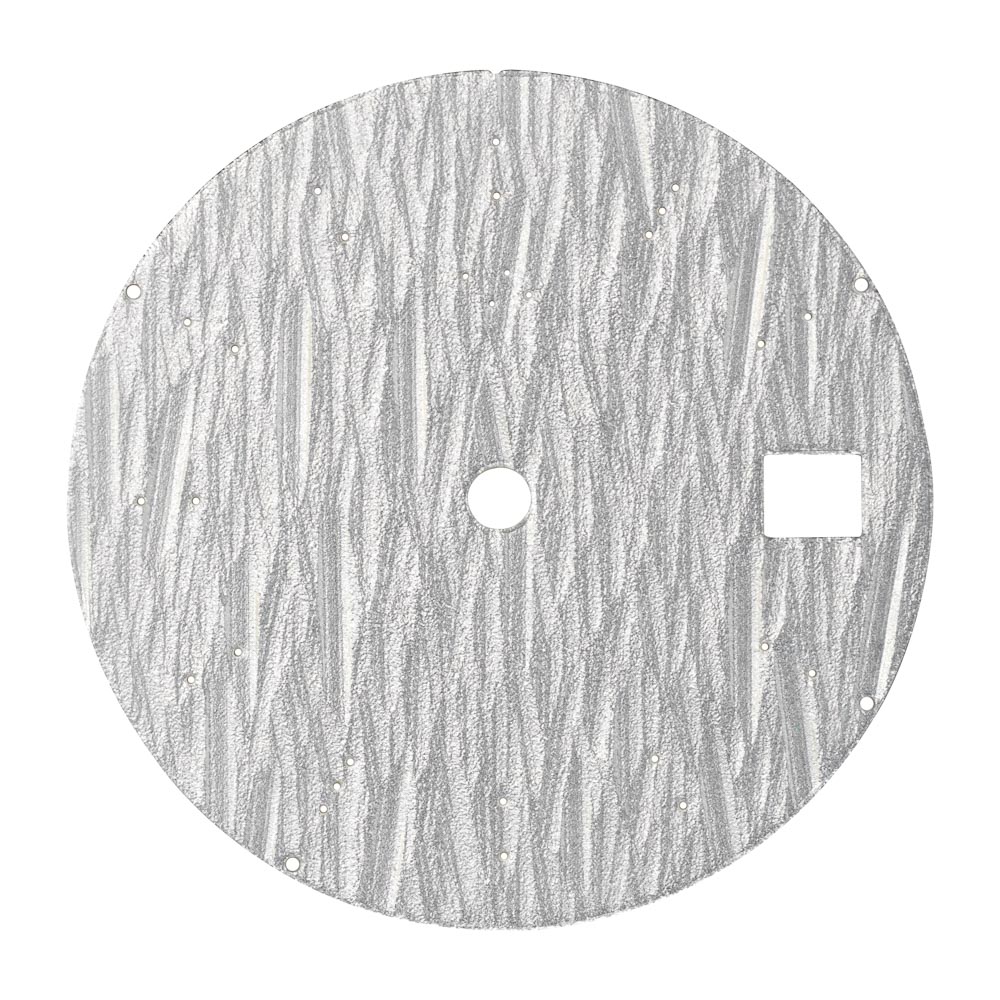

With classic flat dials, this is the moment when paint or lacquer is applied. With the White Birch SLGH005 and its intricate texture, more steps are necessary. The dial is brushed to add vertical strokes and texture, but again, the texture requires a different process. The dial is then silver-plated and coated to protect the colour. Some additional, intermediate steps are then explained in more detail in the article of the GS9 Club, but the most interesting part is the so-called wrap coating.

Indeed, due to the pronounced depth of the pattern, the markers can’t be directly applied to the dial, and the logos/tracks can’t be directly printed on the dial. This would result in uneven positions or oddly placed text. As such, the dial has to be “wrapped” with a transparent top coat to flatten the surface, while revealing the pattern underneath. By adding layers on top of layers of clear coating, the stamped pattern is completely covered and sealed. A preliminary polishing is done to smooth out the thick surface of the top coat and then a second coating and polishing step is executed. In total, we’re looking at about 14 to 15 layers of coating applied to the dial, more than double the normal amount. Once flat and perfectly polished, it’s time for steady hands to apply the GS logo and hour markers, and for the logos and tracks to be stamped on the dial.

The result… one of the most fascinating dials ever created by Grand Seiko. Make sure to have a good read of the GS9 Club article here, to understand the complexity of making the dial of the Grand Seiko White Birch SLGH005.

For more details, visit the websites of the Grand Seiko GS9 Club America and Grand Seiko GS9 Club Europe. Images of the dial manufacturing process used in this article are sourced from Grand Seiko or the GS9 Club.

4 responses

Now I need to know how the other white birch was made. I NEED TO.

This right here is why this hobby is so addictive. Fascinating.

Those seven phases of stamping all look exactly the same to me.

The result is wondeful, though.

still astounished by attention to detail in Grand Seiko range in fact the result is beautiful ! Same requirement and creativity be also seen in some Seiko enamel dial like SPB075J1