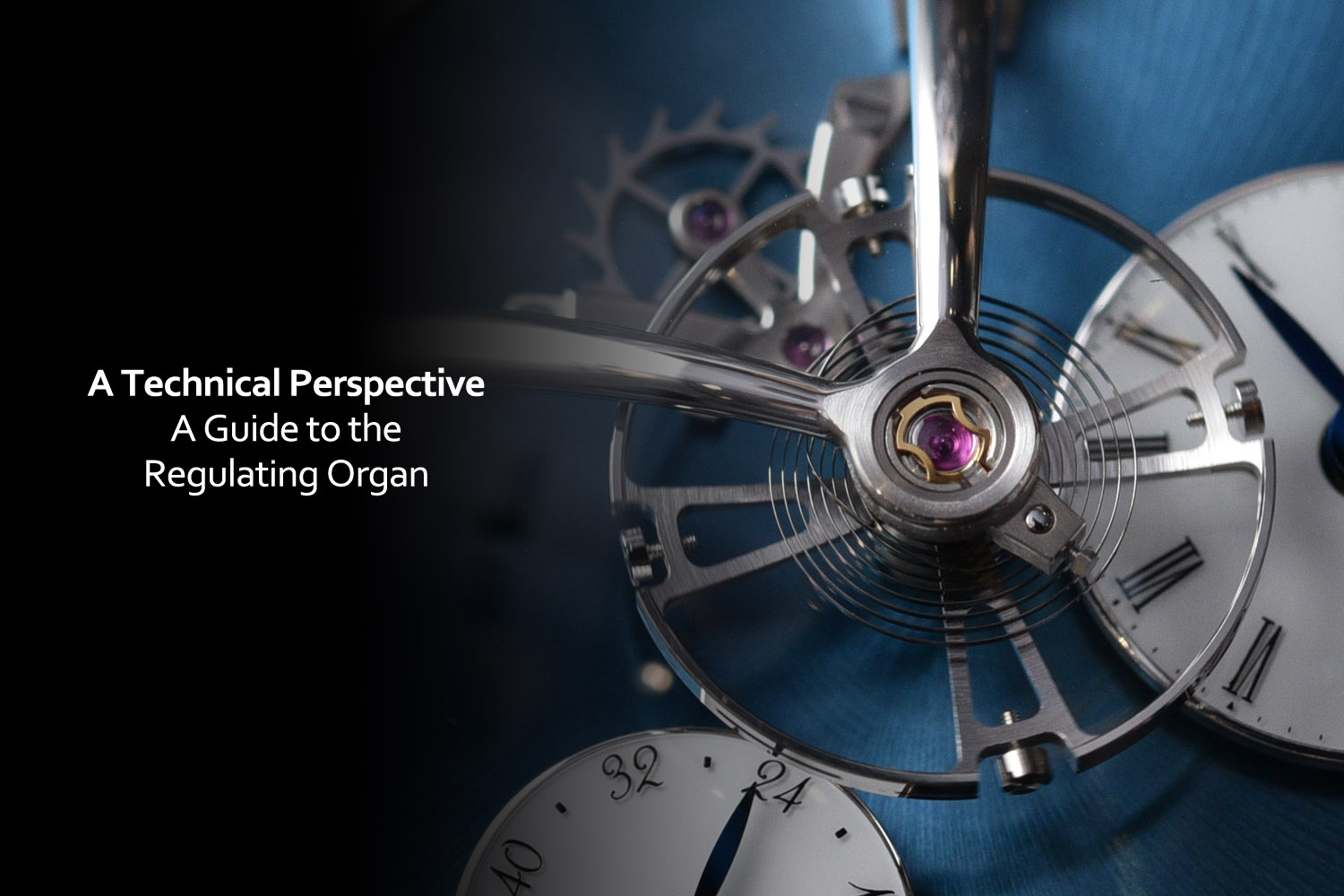

A Complete Guide to the Regulating Organ

Deciphering the most crucial part of a watch, the regulating organ.

The regulating organ of a watch is certainly amongst the most important parts. It is what defines the speed at which the watch will run – and because time is defined by rules, this speed has to be controlled with great care, in order to have the most accurate watch possible. The regulating organ can take several forms, it can use several materials, it has been a field for innovations since watchmaking exists and overall, it is a crucial element of a watch. Here is a guide to understand the regulating organ of a watch.

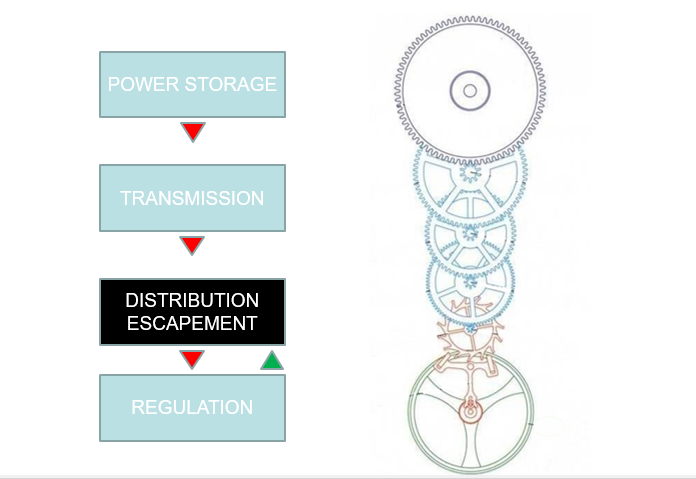

The balance wheel and hairspring represent the regulating organ of the watch. The balance wheel works in conjunction with the escapement. The escapement gives impulses to the balance wheel. In return it is regulated by the balance. The oscillations of the balance wheel regulate the flow of time and is therefore critical for the accuracy of the watch. Each swing of the balance allows the gear train to advance a set amount. Its role is similar to that of a pendulum in a clock. As a pendulum cannot be transported, it needed to be replaced by a device fulfilling the same function for watches.

An extremely thin coiled hairspring ensures that the balance swings back and forth at a constant frequency. Its center part is attached to the balance staff while the outer is to the balance bridge or cock. The duration of each oscillation is determined by the spring elasticity, its length (active length) and the inertia of the balance wheel. Watches can therefore be regulated by adjusting the active length of the spring (shortening the spring makes it run faster) or modifying the inertia of the balance wheel.

Materials

Modern balance wheels are usually made of Glucidur, an alloy with low coefficient of thermal expansion made of copper, beryllium and steel. Glucidur is also hard, resistant and has non-magnetic properties.

Hairsprings are nowadays often made of iron-nickel alloys such as Nivarox, whose elasticity is almost not affected by temperature. Nivarox is an acronym for Nicht variabel oxydfest (Non-Variable Non-Oxidizing). This alloy is in the same category as Invar (FeNi36%) invented by Swiss Nobel prize Charles Edouard Guillaume. If several companies now produce hairsprings, Nivarox-Far has long been an inescapable supplier of hairsprings and assortments (escapement/regulator) for the Swiss watch industry. This company, belonging to the Swatch Group, remains a key supplier for many movement manufacturers.

These modern alloys made unnecessary the use of the complex self-compensating balance wheels. The variation of temperature changes the dimension and the elasticity of the spring, as well as the diameter of the balance wheel. It was a major source of inaccuracy. Some of the greatest watchmakers worked on having opposing effects that would to some extent cancel each other with temperature changes.

More recently, some watchmakers have started to use silicon, to improve the performance of escapements (read our dedicated article here) and oscillators, more specifically crafting hairsprings. Silicon holds a number of properties that make it an interesting material. It is light, non-magnetic, flexible, temperature-resistant, requires virtually no-lubrication and can be manufactured with extreme precision (with technologies like DRIE – deep reactive ion etching – or LIGA – X-ray lithography). Ulysse Nardin was the first to introduce such hairsprings, with the Freak. Rolex, Patek Philippe and Swatch group followed and have conducted research in collaboration with CSEM in Neuchatel. Other high-tech materials were presented, for instance, Zerodur, a zero expansion glass ceramic, by Cartier (for concept watches’ hairsprings). More recently, TAG Heuer presented its first watch equipped with a carbon composite hairspring.

Fighting magnetism is a primary focus. Silicon (and the two developments mentioned above that however have not made it to major serial production yet) is anti-magnetic. Yet, not everyone is a fan of these modern technologies (silicon/carbon composite) and some question whether silicon has its place in a traditional mechanical watch. In 2000, Rolex developed and patented an innovative hairspring in an exclusive alloy of niobium, zirconium and oxygen: the Parachrom hairspring. In 2019, Swatch Group unveiled its Nivachron hairsprings (developed with Audemars Piguet) that “allow a considerable reduction in the influence of the residual effect of a magnetic field on the running of a watch, a reduction by a factor of 10 to 20, depending on the calibre”.

Different types of hairsprings

The shape and attachment of the hairspring naturally determines the way it expands and contracts. While a majority of movements use flat spiral springs, there are other possible shapes of hairsprings. The Breguet overcoil, in which the outer coil is bent up inwards and attached near the balance staff, aims at achieving isochronism (having a constant period regardless of of the amplitude) allowing the spring to ‘breathe’ symmetrically and evenly.

A Breguet hairspring in silicon featuring the eponymous overcoil (left). A Jaeger-Lecoultre Gyrotourbillon spherical hairspring (right).

Helical and spherical hairsprings also aim at improving isochronism. While constituting prestigious and eye-catching solutions, these are complex to manufacture and their three-dimensional nature requires much space.

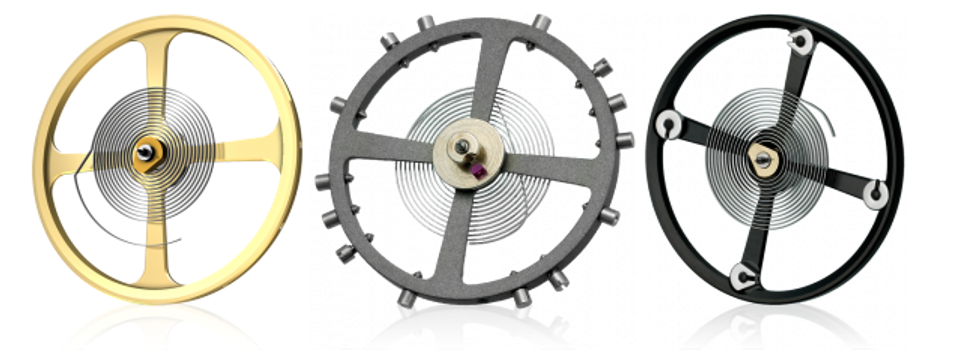

Different types of balance wheels

The main types of modern balance wheels. From left to right: annular, with screws or with weights.

A large number of watches today use annular balance wheels. The precision in manufacturing and the properties of Glucidur allow achieving excellent rate. Higher-grade solutions feature screws or weights to poise and/or adjust the balance.

The recent drive towards vertical integration (in particular because Nivarox-FAR had an almost monopolistic situation on the supply of escapements), several manufacturers have developed their own balance wheels which has enabled them to innovate and differentiate, creating new designs.

Among the most recent developments, independent watchmaker Karsten Frässdorf presented a version of its Spirograph Tourbillon featuring an original balance wheel with auxiliary thermo-compensation.

Adjusting watches

A number of factors and elements affect the functioning of a watch and its rate: the energy supplied to the balance, the adjustment of the beat, hairspring, position of the watch, temperature, magnetism, lubrication and its evolution over time, to name a few. Adjusting the rate of a watch, therefore, involves complex procedures.

Focusing on key operations, there are two main options to adjust the rate of a watch.

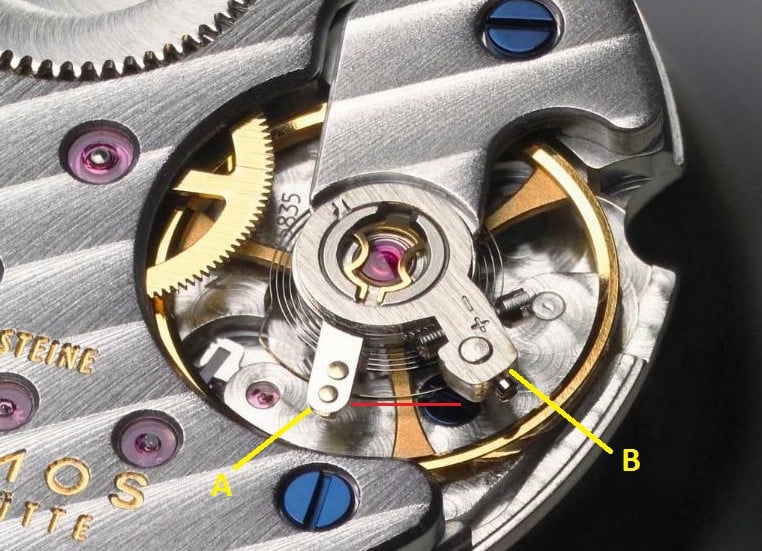

The raquetterie pictured above features a regulator (A). Two downward pins on the regulator hold the spring so that the part of the spring between the regulator and the stud (B) is inactive (part of the hairspring in red above). As a consequence, sliding the regulator determines the active length of the hairspring, hence its rate.

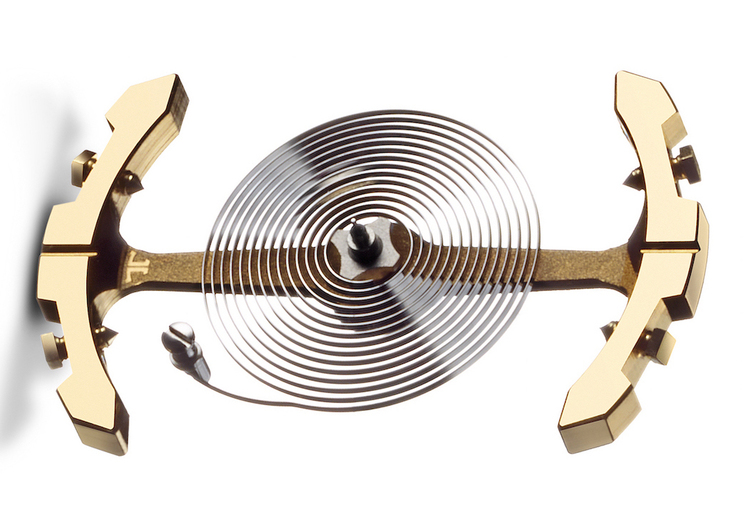

Watches without regulators are called free-sprung. The spring is not held by regulator pins and has a constant length. To adjust their rate, instead of working on the spring length, watchmakers work with the inertia of the balance wheel, moving the screws or weights positioned on the balance.

Free-sprung balance wheels are a high-grade solution, they are more complex to work with but they are meant to time better as certain sources of error are absent with them. Also, they do not risk being affected by shocks that might cause the regulator index to move.

Fighting gravity, the tourbillon

The oscillator and escapement are adversely affected by several factors. New materials allow counteracting the negative effect of magnetism or temperature changes. We will deal with the varying energy delivered to the escapement and balance wheel in an upcoming article. The accuracy of watches is also subject to the influence of gravity. Changes of position have significant effects on the way these keep time, in particular with disturbance in the balance wheel isochronism.

In 1801, Abraham Louis Breguet patented a solution to negate the effects of earth attraction; the tourbillon. A mobile carriage rotating at slow speed (most often once per minute) houses the balance, balance-spring and escapement with the aim to average out positional errors. The tourbillon is regarded as one of the greatest inventions of Breguet and it remains as evidence of skill and craftsmanship of the watchmakers capable of manufacturing this spectacular and captivating complication. After more than 200 years, the brainchild of Breguet is now worn on the wrist and has achieved great diversity. As the tourbillon has become more available in recent years, it has been brought to greater heights with numerous innovations, in particular rotations on several axes.

Unconventional oscillators

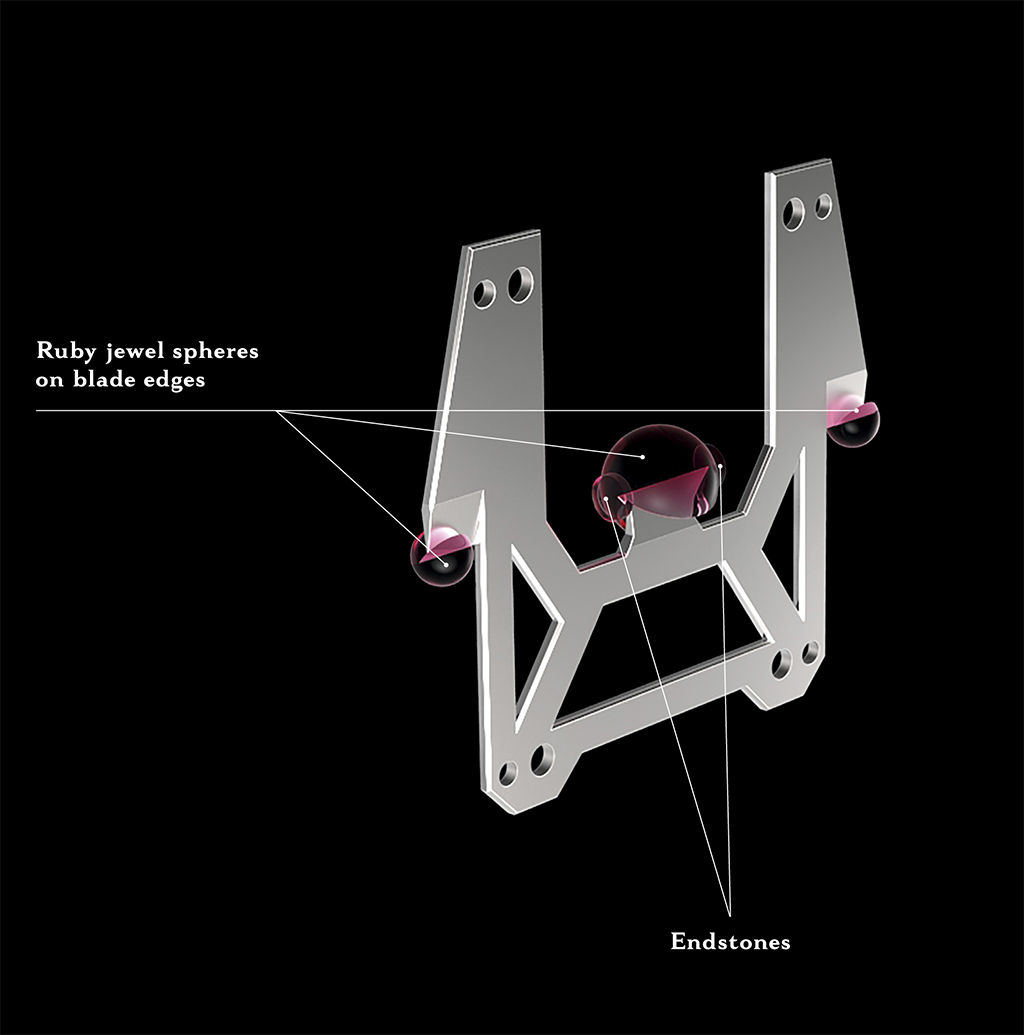

Beyond the traditional balance wheel and hairspring, “unconventional” oscillators have been developed by watchmakers, specifically in recent years together with the development of new escapements and the potentialities offered by silicon, to reach high frequency to enhance precision or to reduce the energy consumption of the movement. Our article on the escapements covers some of the latest innovations to replace the traditional spiral spring such as the Tag Heuer excitatory blade system with linear oscillator fit in the Mikrogirder, acoustic resonators for De Bethune or the innovative balance with flexible blades of the Parmigiani-Genequand escapement. At different levels, all these solutions aim at reaching higher frequencies/low amplitude for the oscillator.

Just before Baselworld 2016, Dominique Renaud, one of the founders of Renaud & Papi disclosed his project DR01 Twelve First, featuring a brand new escapement associated with a blade that vibrates to regulate the escapement, there again combining high-frequency and low amplitude.

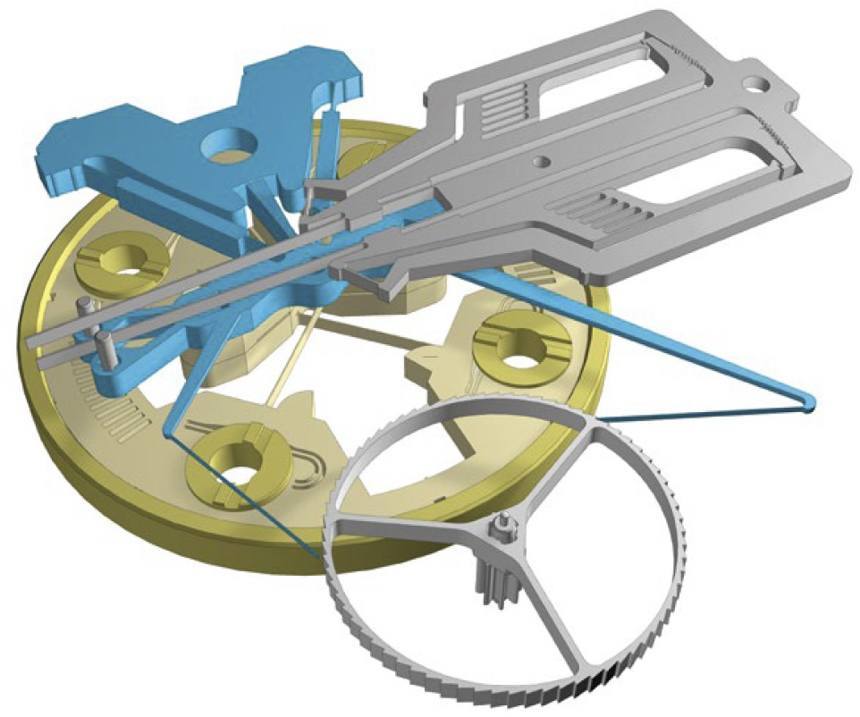

One of the most impressive developments in the field (and probably the only one to have made it to production) is, without doubt, the Zenith Defy Lab/inventor. Presented in 2017, the concept is based on a monolithic oscillator made of monocrystalline silicon developed thanks to the application of compliant mechanisms. The escapement working with the oscillator is very similar to a clock anchor escapement. The anchor is integrated within the oscillator (just like the anchor can be integrated to the pendulum for some clocks!) and works in conjunction with a silicon escape wheel.

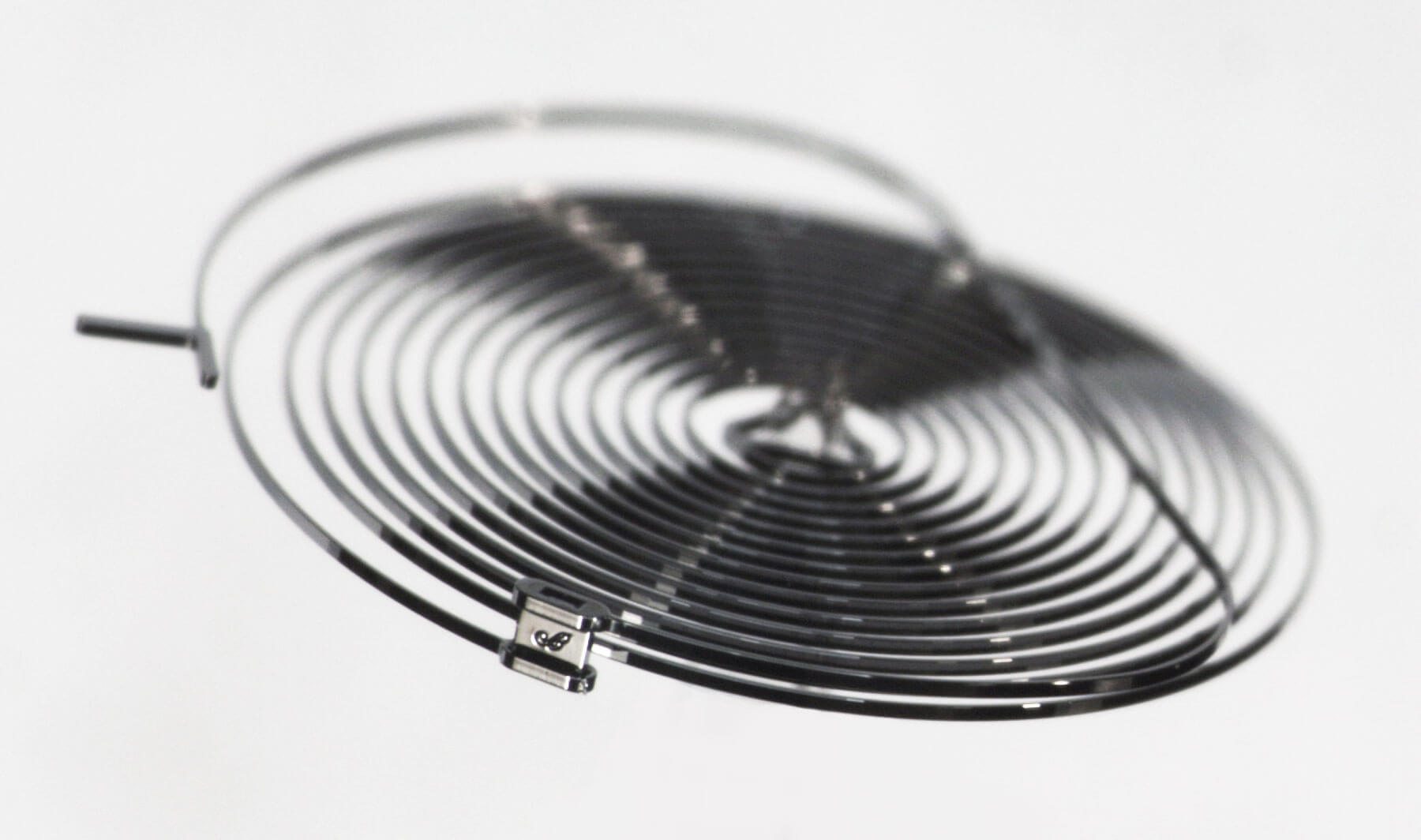

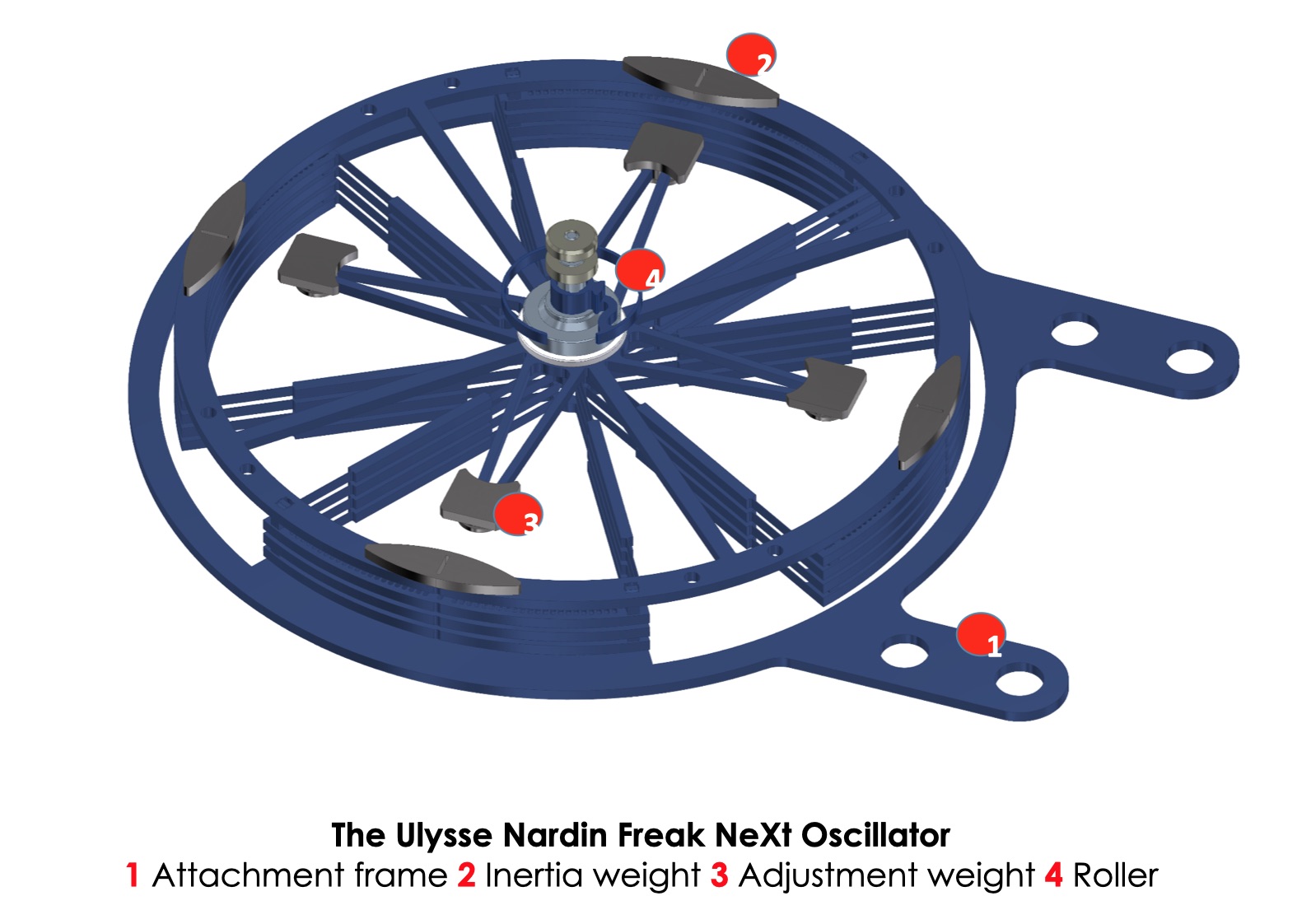

In 2019, Ulysse Nardin presented the Freak Next, a concept watch regulated with an unprecedented oscillator whose three-dimensional architecture is based on flexible silicon blades.

This article was originally published on April 22, 2016. It was updated on April 3, 2020.

9 responses

saw a pocket watch from 1900 made by the London maker ” Goldsmiths and Silversmiths “. it has the screws on the balance wheel.

i now understand how it works. thank you.

Who made the tourbillon with the pivot detent above?

It is a GP tourbillon – pocket watch movement.

Great article, lots of obscure stuff in there that I had not seen before.

As usual monochrome smash it out of the ball park with a well engaging, well in-depth piece of work on my favourite subject, thankyou guys..

Most excellent, please more articles on the technical aspects of watch operation. Kudos to those involved in the production of the article and it’s updating.

@shirley @john @phil Thank you for taking the time to read and comment on the article.

Just discovered this article. Really enjoyed it

as a new SA at one of Swiss watch brands, i always find ur article very helpful. thank you.