Founded Out Of Passion, ZLTD Watches Offers Something Different and Refreshing

A Singaporean-Canadian indie adventure founded by enthusiasts, for enthusiasts.

‘Watches by enthusiasts, for enthusiasts’ is not just a marketing phrase when it comes to ZLTD Watches, but a genuine conviction. It’s about bridging passion, culture and creativity to offer something unique. Singaporean watch nut Z.L. Toh, one half of the brand, started out by spending hours upon hours watching YouTube videos on all things watchmaking. Finding a partner in Canadian watchmaker Raf Dzwonek when developing his first watch, the two joined forces to eventually found ZLTD Watches. Following a sell-out debut piece, Series 1, they have quickly gained attention from the watch-collecting community. Their latest piece, the Series 2, takes things a few steps further, with an inclined balance wheel, dial-side-exposed mechanics, and more! Time to introduce you to this rising duo on the indie watchmaking firmament!

Robin, MONOCHROME Watches – Kenny, everything started with you going down the watchmaking rabbit hole on YouTube. What triggered you into learning the actual craft?

I have always loved watches, and, as with most collectors, I started my watch-collecting journey with the usual Seikos and Casios. In pursuit of knowledge and to learn more about watches, I enjoy reading about them and watching review videos. Notably, I especially enjoy watching review videos from Tim Mosso of the 1916 Company, as his videos are always interesting and informative. The video that led me down the ‘Rabbit Hole’ was a Roger Smith review, and I was simply awestruck by a side of horology I never knew existed. In the video, I recall Tim Mosso delving deeply into the art of traditional watchmaking craftsmanship, from the heat bluing of the watch hands, the rose-engine hand-guilloché dial, the immaculate black polishing of the metal parts and the beautiful anglage on the movement bridges for the finishing. I then started researching other independent watchmakers, like Kari Voutilainen and Rexhep Rexhepi (to name a few), and fell utterly in love with the independent watch brands.

To better appreciate the craft, I had a crazy idea one day: starting my own watch brand with a small series of 15 watches that featured some of the traditional watchmaking skills I have come to love. Namely, the art of black polishing and the heat tempering of the steel hands to a colour. With that, the brand ‘Z.L.Toh’ was born with the Series 1 as the inaugural timepiece.

At what point did Raf enter the stage?

During the creation of Series 1, Raf was the partner I worked closely with to produce the components of the watch (the dial, indexes and hands). After a year of close collaboration, we realised we shared a vision for a watch brand that combines in-house complication modifications with traditional watchmaking crafts. With that, ‘Z.L.Toh’ was rebranded as ‘ZLTD Watches’ with Series 1.5 being the first Series that we launched after the rebranding, and Raf being the master watchmaker behind the brand from Series 1.5 onwards.

Raf, can you tell us more about your watchmaking background?

Raf, ZLTD Watches – My path into watchmaking was pretty organic. I found a box of old Soviet watches in my grandparents’ apartment in Poland and, out of curiosity, started taking them apart. I broke a few at first, but eventually managed to reassemble one—and that was the hook. From there, it turned into a real rabbit hole. I’ve been largely self-taught ever since, learning through hands-on work, research, and years of experimenting at the bench, which in the end matters most.

You started with the Series 1 watch and are now onto the Series 2. Can you elaborate on your debut series?

Chronologically, we first launched Series 1 in November 2023 (see directly below), then Series 1.5 in July 2025 and the Special Series – No.1 and Series 2 watches in November 2025. For Series 1, our goal was to create a great dress watch that featured traditional watchmaking craftsmanship and design elements we know collectors will appreciate. For our first series, a key objective was to highlight the demanding craft of mirror/black polishing. You’ll see this commitment reflected in every hour index on the dial.

Each one undergoes a meticulous, multi-stage process: laboriously polished with various grits of sandpaper, then refined to perfection with pegwood and successive grades of diamond paste. Once polished, each index is then carefully installed onto the dial, piece by piece. To showcase the craft of heat tempering, we’ve chosen elegant Breguet-style hands which are first meticulously high-polished before being heat-treated to a vibrant colour of straw, purple, or blue. For Series 1.5, with a vision for an elegant yet sporty daily beater, we kept the same black-polished indexes and hands design but opted for two vibrant anodised titanium dial variants with a sophisticated brushed finish. The seconds hand are then either heat-treated bronze (for the Aubergine dial) or purple (for the Bronze dial).

Our latest update for Series 1.5 also highlighted a new enhancement to the chapter ring: the minute markers and brand name are now meticulously hand-filled using Japanese Cashew Urushi lacquer. This specific lacquer allows for exceptionally sharp, durable, and aesthetically rich detailing and is chosen for its superior depth and semi-gloss finish. We also implemented a key refinement to the chapter ring, with its inner edge now polished to a high finish. For the daily beater concept, we used an in-house modified Sellita SW330 movement and introduced a ‘jump hour’ feature. With a simple pull of the crown to the first position, you can effortlessly advance the hour hand independently, perfect for crossing time zones, without ever stopping the continuous flow of the seconds hand.

And how do the Special Project watches fit into this?

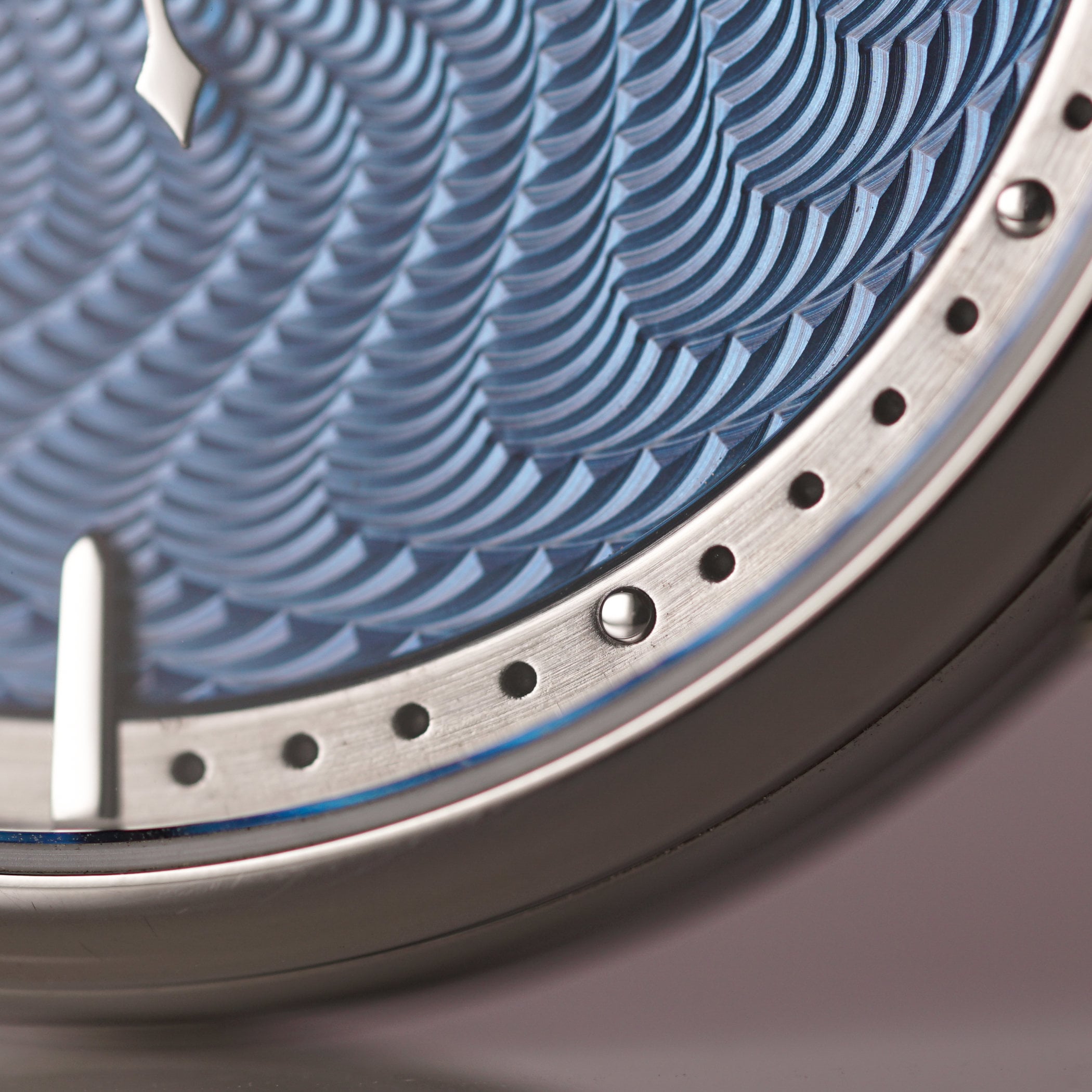

For the Special Project No.1 Watch, this limited edition watch was produced in collaboration with Legacy Watch Co. to thank them for their kind partnership and support. The design inspiration for the Special Project No.1 watch was based on the progress that we have made in our manufacturing and finishing capabilities since Series 1. We wanted to reimagine how we would relaunch Series 1 if we were to do it all over again, with the knowledge and equipment we have now. The dial features true hand-guilloché, cut by an artisan using a traditional Rose Engine (vs. laser-engraved in Series 1).

We continually strive to refine our past designs with every new series. With that, we made two new changes with (1) shifting the hour indexes to the 12, 3, 6 and 9 positions and (2) introducing our new rounded indexes, embedded into the chapter ring at every 5-minute position. Each of these rounded indexes is individually crafted, polished, and manually installed, piece by piece, to provide exceptional visual depth and precision. The design evolution of our indexes was guided by a single principle: how to maintain the brilliance of our polished elements without obscuring the beautiful underlying guilloche dial.

For the hands, we also debuted our signature hand style with a design that will define our future series of watches. Drawing inspiration from the different forms of traditional spear tips, we have created hands that are both highly legible and visually distinctive, reflecting our commitment to bespoke design at every level.

For the movement, we used an extensive in-house adaptation of the Sellita SW210. We replaced the conventional brass components with custom-manufactured stainless steel bridges, enabling us to achieve a higher degree of polish on the chamfers. We also made changes to the architecture, and it now features a three-quarter plate finished with a circular Côtes de Genève. Lastly, our logo has been engraved on the movement, and the engraving has been hand-filled with Japanese Cashew Urushi Lacquer. While the current movement features Ratchet wheels with a ‘snailing’ finish, please note that the 10 production pieces will be upgraded with mirror-polished ratchet wheels instead. Due to the extensive upgrades to the movement, we have cheekily decided to call this movement our ‘RD210’ movement.

Lastly, we have always believed that the wearing experience of a dress watch depends significantly on the quality of the strap. Our watches are paired with a leather strap that is handcrafted in partnership with Atelier Kai (a leather artisan based in Singapore) for his amazing straps. With every strap being meticulously hand-stitched and tailored to each customer’s specific wrist size.

The Series 2 looks quite unique. What’s the inspiration behind it?

Truth be told, for Series 2, the initial design conception was a ‘small seconds’ watch, as that seemed like a natural evolution from a ‘centre seconds’ watch as seen in Series 1. However, Raf had an interesting idea for something different, and after a year of rigorous development, we are immensely proud to unveil the ZLTD Series 2: an ambitious project powered by our in-house developed “RD01” Movement, featuring a unique 20-degree inclined balance wheel. Series 2 continues our commitment to in-house finishing/manufacturing and the technical challenge of developing in-house complication modifications. This is also the direction for our future brand launches, and Series 2 defines our vision.

You use the ETA 6498 as a base, but put a lot of work into it. Can you elaborate on the design, construction and finishing?

Total development of the ‘RD01’ movement took approximately 12 months from start to finish. All components outside the gear train are produced in-house in our Canadian workshop. The movement uses a heavily in-house modified ETA 6498 gear train, chosen for its long-term serviceability and repairability by any watchmaker familiar with ETA movements. For Series 2, the movement bridges are crafted from stainless steel instead of conventional brass for its hardness and finished entirely in-house. This material choice enables us to achieve a brighter, more brilliant mirror polish on the anglage and chamfers.

The stainless steel bridges are sandblasted, and the polish on the anglage contrasts really nicely beside the matte black mainplate (almost like a ‘Yin-Yang’ effect). Overall, we wanted the architecture to be semi-skeletonised: the actively moving components are visible and engaging, while slower-moving elements like the mainspring barrel are intentionally hidden. Achieving symmetry was one of the biggest challenges in the design, but it was worth the effort. It gives the movement a sense of balance and calm, both mechanically and visually.

You’ve also opted for an inclined balance wheel. Can you tell us more about that?

Other than the great visual impact of an inclined tilt, the 20-degree inclined balance wheel also helps improve timekeeping, primarily by averaging out positional errors caused by gravity. The standard balance wheel is also upgraded to a screw balance wheel, which is then installed at a 20-degree angle using our in-house developed movement.

What can you tell us about the finishing of the other components of Series 2 – the dial and hands?

For the dial side, collectors will have the option of either a vibrant anodised titanium dial (Aubergine or Blue) with a sophisticated brushed finish that is done in-house or a hand-guilloché dial. For production, Series 2 will also feature mirror-polished screws instead of heat-blued screws – a decision made to harmonise perfectly with the overall aesthetic. For the hands, Series 2 also features our signature Spear-shaped style hands, which are manufactured and mirror-polished in-house.

To indicate the seconds, a rotating seconds dial sits below the main dial, adding depth to the watch. And to indicate them, a heat-treated purpled arrow hand is also installed. For the production models, the seconds dial will be engraved and hand-filled with lacquer to denote the 15th, 30th, 45th and 60th seconds.

So a lot of work is done in-house!

Absolutely. We’re not like most watch brands in the sense that we are in a unique position to engineer and manufacture high-precision movement components completely in-house. We have our own CNC machines, and this resource gives us control over our watch creation and opens new doors for developing even more unique complications down the line. Other than the watch cases, movements (in some cases) and leather straps, most of the other components are made and finished in-house in our workshop.

This Series 2 model, which you presented in a run of 20 pieces, is all sold out. Will there be others along the same design?

As a brand, we plan to use an iterative approach to refining our catalogue. This means we will keep our Series of watches and produce new pieces annually, with new innovations/changes from the previous iteration. In short, yes, we do plan to launch new variants of Series 2 in the future. With the first run being sold out, I can share that we are already looking into the next Series 2 design.

What are your goals with ZLTD as a brand? What do you hope to achieve in the future?

As mentioned, we would like to continue developing in-house complications while remaining committed to ‘time-honoured’ traditional watchmaking craftsmanship and showcasing them in our next Series of Watches. We are currently planning Series 3 and Series 4, which we plan to debut in 2026. However, in lieu of our capacity and focus on in-house manufacturing and finishing, we expect our annual production of watches to not exceed 100 timepieces. Raf and I are greatly humbled and grateful for the immense support of the watch community thus far, and we will endeavour to continue producing Watches that resonate with the watch community.

If people want to learn more about you two and your watches, how can they get in touch?

People can always check out more details on our website and reach out with any questions. We’re always very happy to be in touch with enthusiasts and collectors. We also share regular updates on our Instagram page, and people can get in touch there, too. Thank you very much for the kind support!

For more information, please visit ZLTDWatches.com.

5 responses

When MB&F, Gruebel Forsey, and Armin Strom get together for a quick mashup.

I love this young brand. Have ordered multiple series already. An eventual in-house movement would be quite the accomplishment

The finishing on the movement looks surprisingly poor for Swiss, but there’s definitely potential here.

It looks like a Chinese “hommage” to the Breguet La Tradition.

Very cool! I met Raf a few times at a local RedBar meeting in Calgary, Alberta. I saw some of his earlier works and was impressed with the watches, especially the dials. Well done here RAF!