Why are Toothbrushes so Important in Russian Watchmaking?

A simple thing that says a lot about the brand’s mentality.

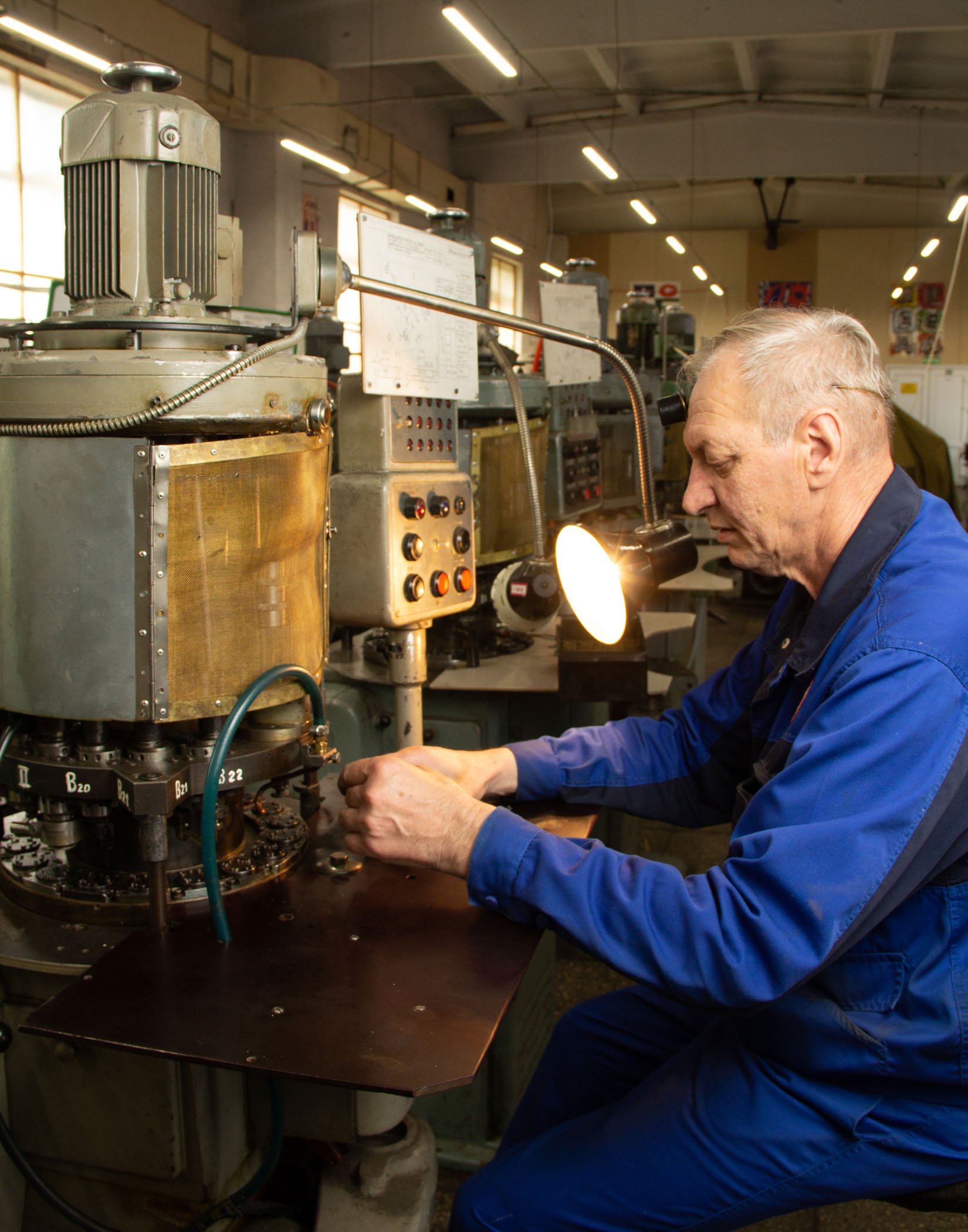

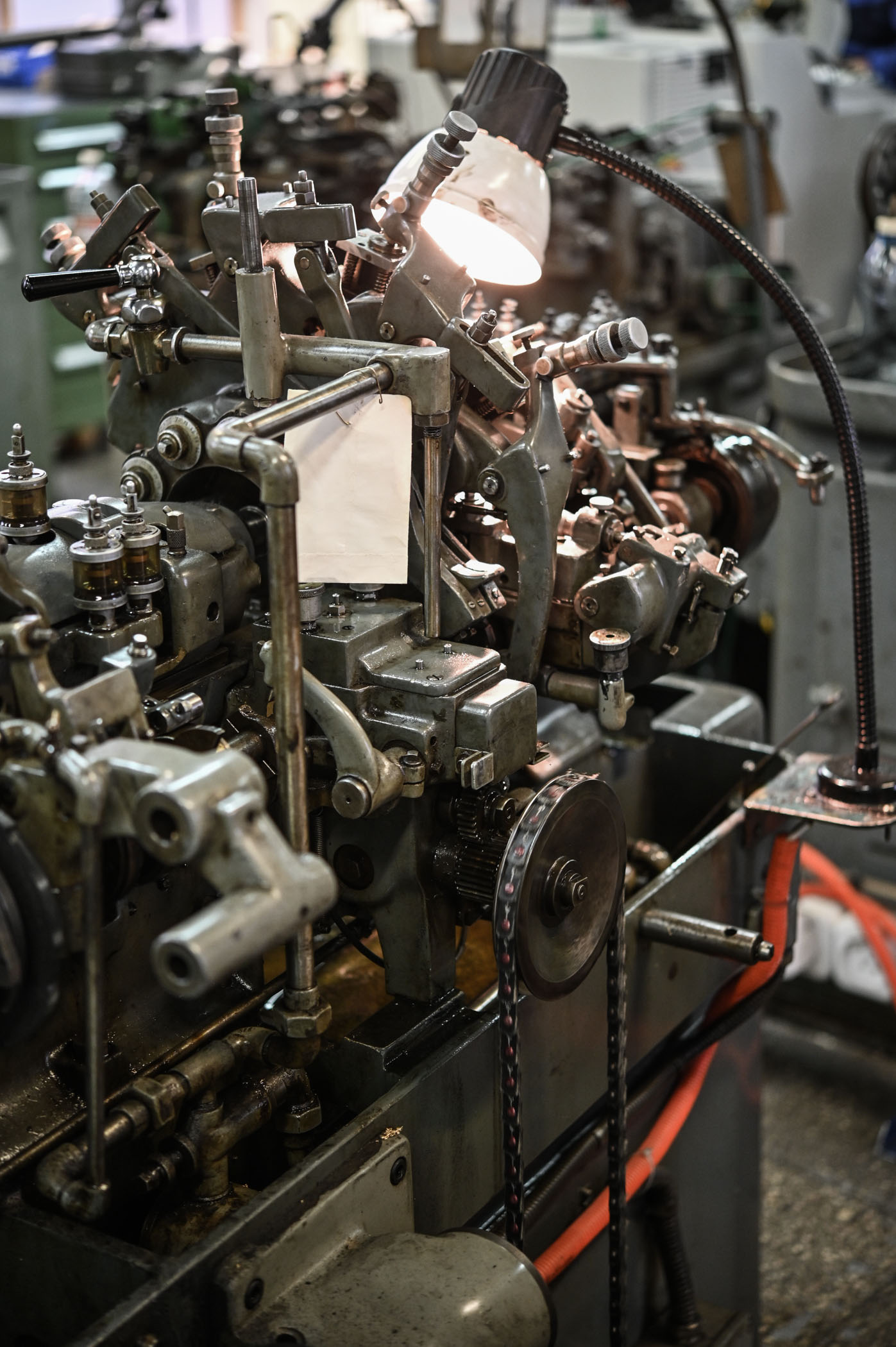

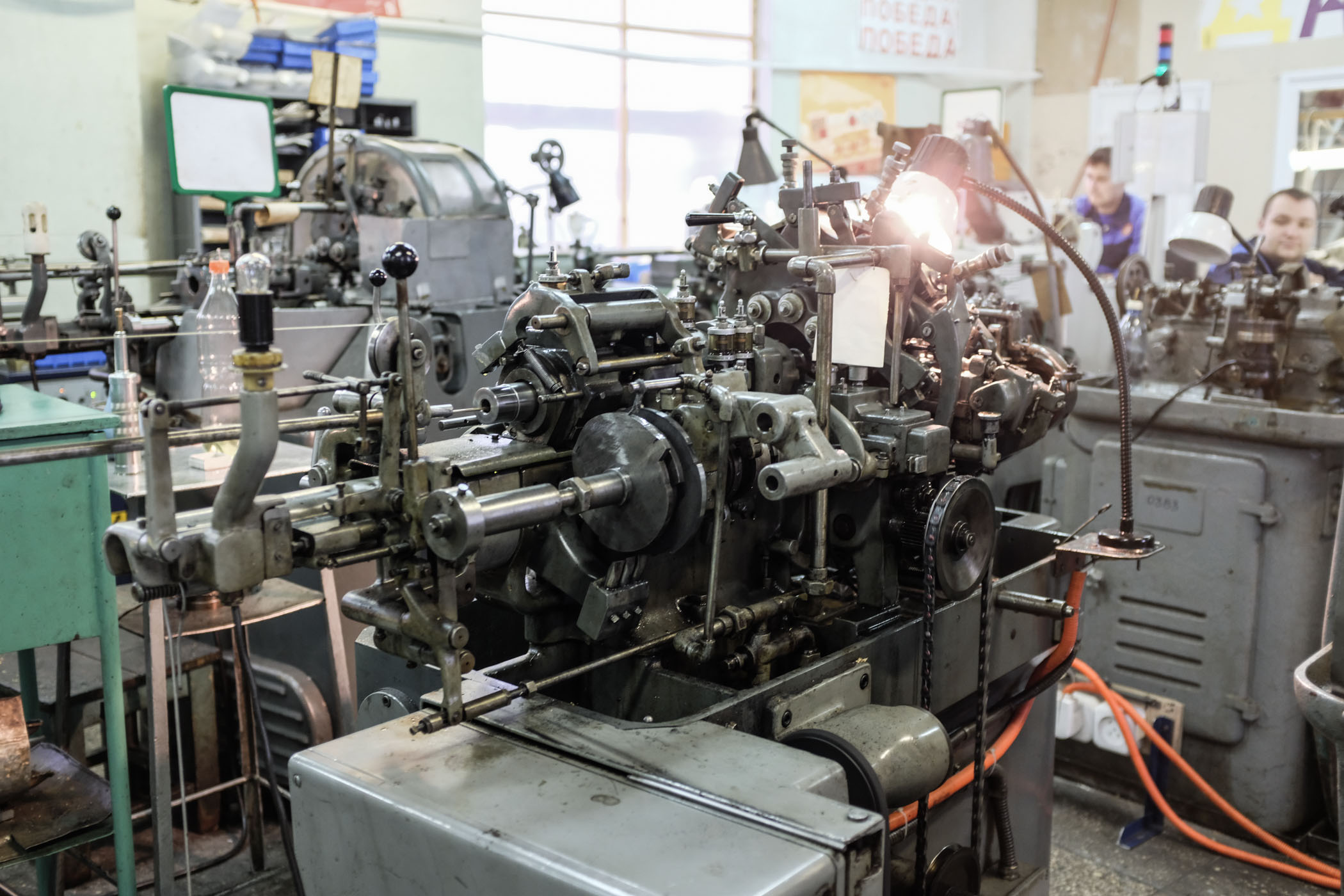

Anyone who visits the Raketa watch factory in Saint Petersburg will be surprised by the appearance of the machines in the main production hall. They seem to come from a different age. These days most watch factories use modern machinery with computerised numerical controls, but most of Raketa’s machines still date back to Soviet times. As we’ve already seen when I wrote about my visit to the factory, they look distinctly old-fashioned and out of place in the 21st century! And if the fact that Raketa’s manufacture has its own in-house choir might surprise you, there is something else that is just as surprising, and it has to do with toothbrushes… Why? Keep reading!

Olga, Raketa’s Production Manager, explains: “Our machines are rather simple to use, but they allow us to achieve very high precision. They are easy to maintain as they don’t have any complex hydraulic systems, electronic circuits or computer software. As long as they are properly maintained, they will still be working in 100 years’ time.”

But what surprised me even more when I visited the Raketa Factory last year is that a lot of these machines have toothbrushes screwed into their frames, converting them into an integral part of the machine.

In other cases, these toothbrushes are used manually by Raketa’s watchmakers or workers. Lightyears behind the laboratory-like premises of Omega…

What is the purpose of these toothbrushes? The largest components of a mechanical movement are the plates, bridges and rotors. Producing these components is all about transforming a flat piece of brass into an extremely precise and complex component. This is done by cutting metal away with high-speed rotating cutters. Shavings are produced during the milling process, and the role of the toothbrush is to scrub the workpiece (and the holder on which the workpiece is fixed) and remove the shavings. This is an exceptionally important step: any dirt that remains on these surfaces can affect the precision of the subsequent milling operations and at a later stage, the precision of the watch itself.

As Olga explained: “I have never visited Swiss watch factories, but their modern milling machines must necessarily have an equivalent function – except that it must be done with some kind of more complex technology. We just use a toothbrush!” Pragmatism and resourcefulness at their best!

Nathalia, Raketa’s Supply Manager, went further: “Toothbrushes are certainly one of the most important consumable instruments of our factory: I buy them in boxfuls!”

This use of toothbrushes says a lot about Russian mentality. Russians are well known for simple and sturdy constructions. Why make something complicated when you can make it simple? This reminds me of the story about the Americans at NASA spending over a million dollars to develop a pen that would work in space without gravity – instead, the Russians relied on a pencil!

This Russian mentality is not only reflected in Raketa’s machines and production process but is also reflected in Raketa’s mechanical movement. This mechanism has a simple, robust engineering construction that dates back to the creation of the Raketa brand in 1961 and has undergone few changes since then. Exactly like the Russian “Soyuz” rocket launcher also developed in the 1960s, which, thanks to its simplicity, has become the most used space rocket in the world to this day.

As Ludmilla, Raketa’s Chief Engineer, explained: “Many people ask if one day we will develop a tourbillon for the Raketa mechanical movement. The answer is definitely ‘No!’ Not because it is too difficult for us, but simply because it doesn’t correspond at all to Russia’s mentality: tourbillons are an incredibly beautiful complication, but they are very fragile and don’t serve any useful function in a wristwatch. We prefer to do simple, useful things, such as Raketa’s 24-hour movement, which allows submariners to distinguish day from night at the depths of the oceans and cosmonauts to distinguish day from night in space.”

Ludmilla also told me why Raketa doesn’t want to change this old-school way of working: “First of all, why change something that works? Secondly, many European watch specialists and journalists who visit our factory recommend us not to change this way of working because it carries a very strong human touch: they tell me that we work like the Swiss worked 50 years ago!” And I am definitely one of these journalists!

It’s heartening to see how every machine is manually adjusted and operated by a man or a woman who transmits a bit of their soul to every single component they produce. This is really what watchmaking is all about: human emotions! You will certainly find plenty of that at the Raketa watch factory.

“I have worked at the Raketa factory since 1984. I saw first-hand how our factory survived the painful years of the Perestroika and the 1990s when failing communism collapsed and was replaced by brutal capitalism,” explains Yuri while scrubbing away the shavings produced while milling the rotors of Raketa’s automatic movement with a toothbrush. “Our way of working, tested over the past 60 years, is simple and efficient. This simplicity enabled us to continue working in these very difficult times. I would not change my toothbrush for anything else!“

Well, Yuri, don’t change it! These are the kind of anecdotes and fun facts that bring such authenticity and humanity to the watches produced by Raketa.

For more details about the brand, visit www.raketa.com.

5 responses

and this is why I love my Russian watches!

Great article.

Very interesting and it is not necessary to computerize this working environment!

jpl

ONE COMPUTER VIRUS and you have billion € paperweight

Love it. Cheap and cheerful watches.

I’ve purchased my Raketa Baikonur recently I am blown away by quality and attention to details. Hopefully Raketa will get attention and popularity they deserve. A truly unique manufacturer.